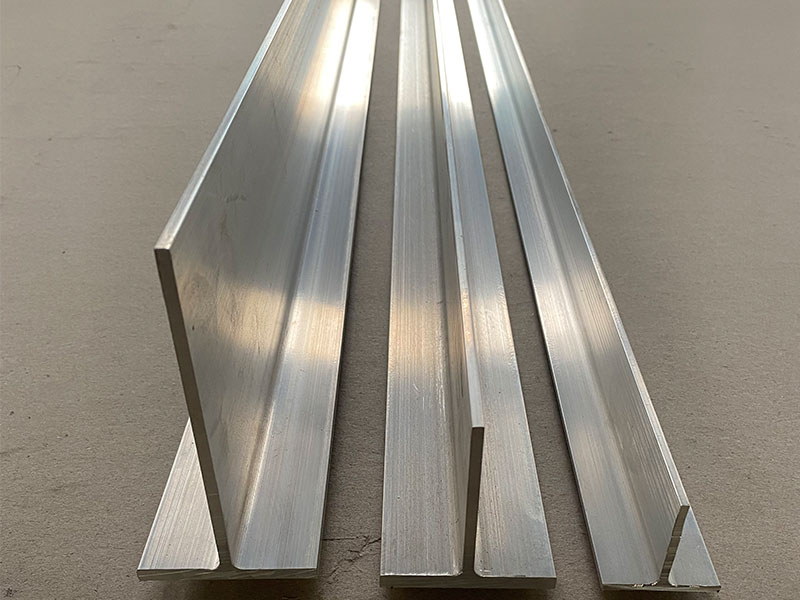

6061 Marine Aluminum Z Shaped Sections for Marine Frame Reinforcement

6061 Marine Aluminum Z Shaped Sections for Marine Frame Reinforcement

Marine structures rarely fail because one component is "weak." They fail because loads travel through the hull in complicated paths, concentrate around cutouts and joints, and keep repeating under vibration, wave slap, and thermal cycling. From that angle, 6061 marine aluminum Z shaped sections are less like simple profiles and more like load-routing hardware: they guide stress where you want it to go, while keeping weight low and fabrication practical. For frame reinforcement, a Z section behaves like a quiet problem-solver-stiffening plating, bridging transitions, and offering a clean way to attach secondary members without bulky brackets.

Why a Z profile works so well in marine frames

A Z shaped section combines two flanges offset by a web. That geometry is valuable in marine reinforcement because it creates separation between fastening planes. In real builds, you often need one flange to sit tight against hull plating while the other flange becomes a convenient shelf for longitudinals, stringers, deck beams, or equipment rails. The offset reduces interference, improves access for welding or riveting, and helps avoid the "stacked thickness" that can trap moisture and promote crevice corrosion.

From a structural viewpoint, Z sections provide good stiffness-to-weight in the direction that matters: resisting local panel buckling and increasing section modulus around frames. They are especially useful where a flat bar would oil-can, and where an angle would force both attachment faces into the same plane.

Functional advantages in 6061 specifically

Choosing 6061 aluminum for Z sections is a strategic compromise that marine builders appreciate: it offers solid strength, dependable machinability, and widely understood welding behavior. Unlike some higher-strength alloys that trade away corrosion resistance or weld performance, 6061 sits in a sweet spot for mixed fabrication methods.

functional strengths of 6061 marine aluminum Z sections include:

Efficient frame reinforcement with minimal weight penalty

A properly sized Z section can increase frame rigidity without needing thicker plate. In high-cycle marine service, lowering mass also reduces inertia loads and fatigue stress.

Practical joining options

Z sections are friendly to MIG/TIG welding, and also work well with mechanical fastening when isolation is used. The profile naturally creates "landing areas" for clips, brackets, and fasteners.

Corrosion resistance suitable for marine environments

6061 resists atmospheric and freshwater corrosion well, and performs reliably in marine air and splash zones when correct surface prep, drainage, and coating systems are used. For immersed or highly aggressive chloride exposure, builders often combine 6061 with protective coatings, anodes, and sensible design clearances.

Dimensional stability and consistency

Extruded Z profiles in 6061 tend to maintain straightness and predictable tolerances, which matters when aligning long runs along a hull or superstructure.

Common marine applications for Z shaped sections

In practice, marine frame reinforcement is rarely a single "use case." Z sections show up wherever designers need stiffness, an offset mounting surface, or a clean transition between components.

Typical applications include:

Hull frame and transverse reinforcement where plating needs anti-buckling support

Longitudinal stiffeners along bottom plating and side shell, especially near high-slap regions

Deck and cabin framing where an offset helps route wiring, plumbing, or insulation

Hatch coamings, bulwark supports, and door frame reinforcement

Equipment foundations, console supports, and internal racking where a rigid edge member is needed

Retrofit reinforcement on existing aluminum boats where minimal cutting and easy fit-up are priorities

A distinctive advantage in retrofit work is that a Z section can often be added as a "cap-and-shelf" stiffener: one flange bonds to an existing surface, while the other flange becomes a new attachment plane without reworking the original structure.

Alloy tempering choices and what they mean on the shop floor

Temper is where 6061 becomes a "tunable" material. For marine Z sections, the most common tempers are 6061-T6, 6061-T651, and 6061-T4.

6061-T6 is solution heat-treated and artificially aged. It delivers higher strength, making it a strong default for frame reinforcement members.

6061-T651 is similar to T6 but stress-relieved by stretching, improving dimensional stability and reducing warpage risk in machining. This can be valuable when Z sections are drilled, milled, or slotted for complex assemblies.

6061-T4 is solution heat-treated and naturally aged. It is softer and easier to form; some builders choose T4 when additional bending or forming is required before final assembly.

For welded marine structures, it's important to remember a practical truth: welding locally reduces strength in the heat-affected zone. Many designers account for this by sizing the section appropriately, using intermittent weld patterns where permitted, and focusing on fatigue-friendly details like smooth transitions and controlled weld starts/stops.

Implementation and fabrication standards commonly referenced

Marine aluminum projects typically align product supply and fabrication with a mix of ASTM, EN, and marine classification guidance. For 6061 Z shaped sections, the following standards are commonly used as reference points:

ASTM B221 for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes

EN 755 for aluminum extruded products (tolerances and mechanical properties, depending on region)

AWS D1.2 for structural welding of aluminum

Marine classification rules (ABS, DNV, Lloyd's Register) where applicable for commercial vessels, especially regarding weld procedures, inspection, and scantling expectations

Exact compliance depends on vessel type and customer requirements, but these references help ensure consistency in chemistry, temper, dimensional tolerances, and joining quality.

Typical parameters and specification notes

Because Z sections are extrusions, dimensions vary widely. Buyers usually specify a combination of geometry, temper, length, and surface condition:

Alloy: 6061

Temper: T6, T651, or T4 depending on fabrication plan

Profile form: Z shaped extruded section, equal or unequal flanges

Thickness range: commonly in the few-millimeters to low-teens range, selected by load and weld strategy

Length: fixed lengths for production efficiency or cut-to-length for retrofit and custom yards

Surface: mill finish; optional anodizing or primer systems depending on corrosion strategy

Straightness and twist tolerances: per ASTM B221 or EN 755 as agreed

A helpful purchasing viewpoint is to treat a Z section as a structural component, not just "stock." Communicating the joining method, coating plan, and service environment upfront helps select the best temper and surface prep.

Chemical composition of 6061 (typical limits)

Below is a commonly used chemical composition table for AA 6061 (weight percent). Always confirm with the mill test certificate for your batch.

| Element | Composition (wt. %) |

|---|---|

| Silicon (Si) | 0.40–0.80 |

| Iron (Fe) | 0.00–0.70 |

| Copper (Cu) | 0.15–0.40 |

| Manganese (Mn) | 0.00–0.15 |

| Magnesium (Mg) | 0.80–1.20 |

| Chromium (Cr) | 0.04–0.35 |

| Zinc (Zn) | 0.00–0.25 |

| Titanium (Ti) | 0.00–0.15 |

| Others (each) | 0.00–0.05 |

| Others (total) | 0.00–0.15 |

| Aluminum (Al) | Balance |

The "personality" of 6061 comes largely from the Mg-Si system, which responds well to heat treatment and provides a dependable blend of strength and corrosion performance for marine construction.

A practical, marine-first way to think about 6061 Z sections

Related Products

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum Z Shaped Sections for Saltwater Resistant Engineering

In the world of marine construction, material selection is critical for ensuring durability, strength, and resistance to harsh environmental conditions.

View Details6061 Marine Aluminum Channels for Offshore Boat and Platform Construction

6061 Marine Aluminum Channels are a premier choice for offshore boat and platform construction owing to their combination of strength, corrosion resistance, and excellent workability.

View Details6061 Marine Aluminum Channels for Boat Deck and Frame Construction

6061 marine aluminum channels are extruded structural profiles manufactured from 6061-T6 (or T6511) aluminum alloy, engineered specifically for marine applications such as boat decks, hull framing, stringers, railings, and equipment mounts.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details

Leave a Message