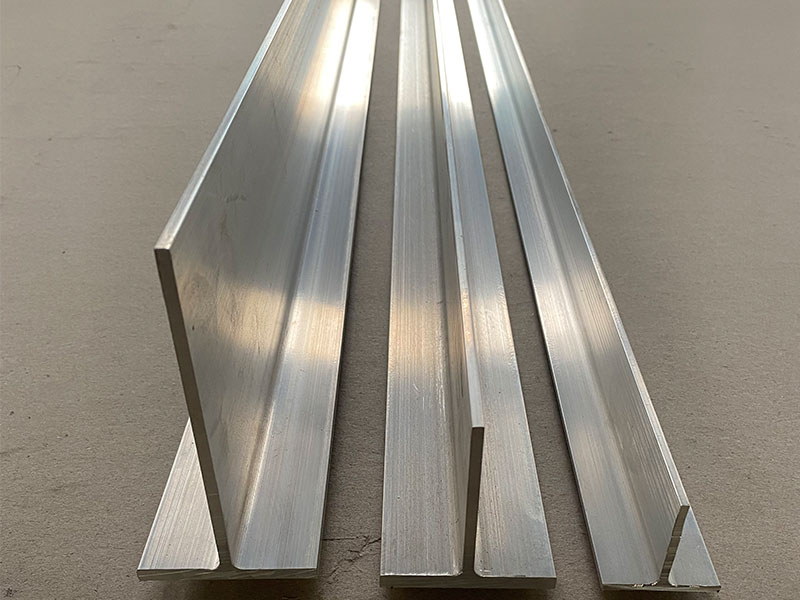

6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks. These unique profiles combine the resilience of aluminum alloys with shape engineering versatility, perfectly tailored for seaworthy frames, bracing systems, and modular structure designs on ships and offshore platforms.

Why 6061 Alloy?

6061 Aluminum alloy is an aviation- and marine-grade wrought alloy channeled into extensive use due to its excellent strength-to-weight ratio, corrosion resistance, and weldability. The aluminum-magnesium-silicon alloy primarily comes under the 6XXX series reflecting its tempering and composition standards governed by ASTM B221 and ISO 6361 certifications.

Z Shaped Sections: Structural Benefits

The "Z" profile, compared to flat bars or square tubes, offers enhanced moment of inertia and rigidity per unit weight owing to its geometric design:

- Structural Advantage: Z shapes provide superior flexural stiffness—critical for marine framing that must endure heavy dynamic loads such as waves and equipment vibrations.

- Compatibility: Easy to integrate with various panel and deck design layouts due to their longitudinal and torsional strength.

- Weld and Fabricate Friendly: Thanks to the machinability of 6061 alloys, these profiles lend themselves well to CNC milling, bending, and TIG/MIG welding with minimal heat distortion.

Technical Parameters of 6061 Marine Aluminum Z Sections:

| Parameter | Spec (Example) |

|---|---|

| Alloy | 6061 |

| Temper | T6 (Solution Heat-Treated & Artificially Aged) |

| Density | 2.70 g/cm³ |

| Yield Strength | ≥ 275 MPa |

| Tensile Strength | 310 - 350 MPa |

| Elongation at Break | ≥ 8 % |

| Corrosion Resistance | Excellent against saltwater |

| Section Dimensions | Custom thickness 3-12 mm, height 20-150 mm, scribing according to CAD specs |

| Surface Finish | Mill, anodized, or custom marine-grade coatings |

Chemical Composition by Weight (%)

This metallic recipe uniquely balances performance; critical elements include magnesium for structural strength and silicon for corrosion control.

| Element | Content (%) |

|---|---|

| Aluminum (Al) | Balance (approx. 97.9+) |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Copper (Cu) | 0.15 – 0.4 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Manganese (Mn) | ≤ 0.15 |

| Iron (Fe) | ≤ 0.7 |

| Others | ≤ 0.15 total |

Implementation & Industry Standards

For marine custom frames, correct application programmes mandate adherence to ASTM B221 norms for extrusion quality, ISO 9227 for corrosion testing, and AWS D1.2 standards governing welding methods for shipbuilding aluminum. The Z section extrusions be tested for mechanical properties during fabrication, ensuring strict compliance with performance and dimensional precision.

Tempering & Heat Treatment Process

The T6 temper affirms solution heat treatment followed by artificial aging. This two-step process heightens mechanical durability especially for marine use:

- The alloy is heated to around 530 °C, rapidly quenched to lock matrix elements,

- Then artificially aged at approximately 160 - 180 °C for several hours to achieve peak hardness.

This metallurgical conditioning provides reliable strength without compromising ductility, a critical factor in absorbing impact and resonant forces performing underwater.

Advantages in Marine Frame Customization

The fusion of 6061 alloy properties with the Z shaped custom sections optimizes weight-saving with outstanding stiffening action—a core demand for naval architects and marine engineers:

- Reduced hull weight directly translates into better fuel efficiency and enhanced speed for vessels.

- Resistance to oceanic corrosion mitigates maintenance costs,

- Structural adaptability makes retrofitting and modular upgrades easier at shipyards.

Related Products

Marine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

6061 Marine Aluminum Channels for Custom Marine Component Fabrication

When it comes to constructing reliable, corrosion-resistant, and durable marine structures, the choice of material is pivotal. Among several options.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details

Leave a Message