Marine Grade Aluminum Solid Bar for Shipbuilding Reinforcements

In modern shipbuilding, material selection is paramount to ensure strength, durability, corrosion resistance, and lightweight design. One of the most critical materials used in this domain is the Marine Grade Aluminum Solid Bar, which plays a vital role in shipbuilding reinforcements.

Why Marine Grade Aluminum Solid Bar for Shipbuilding Reinforcements?

Unlike standard aluminum, marine grade aluminum solid bars are specifically engineered to endure harsh maritime environments. Their applications include structural reinforcements for ship hulls, frames, bulkheads, and deck fittings, where both mechanical strength and corrosion resistance are non-negotiable requirements.

Working with marine-grade aluminum solid bars for shipbuilding reinforcements presents unique challenges compared to other applications. The primary concern is ensuring consistent material properties throughout the entire bar, especially given the often extreme stresses and corrosive environments these components endure. We've seen instances where seemingly minor variations in alloy composition, even within the acceptable tolerances, can lead to premature fatigue cracking or stress corrosion cracking under prolonged saltwater exposure. Therefore, rigorous incoming inspection, including metallurgical analysis and tensile testing, is critical. We also meticulously track the heat treatment process to guarantee the optimal strength and corrosion resistance. Furthermore, the machining and welding processes require specialized expertise to avoid introducing defects that could compromise the structural integrity. Improper welding, for instance, can create stress concentrations that significantly reduce the lifespan of the reinforcement.

Beyond the material itself, the design considerations for these reinforcements are paramount. We’ve found that simply specifying a larger diameter bar isn't always the optimal solution; a properly designed, smaller section can be significantly more effective. the specific loading conditions, fatigue cycles, and the interaction with surrounding structures is vital for maximizing strength while minimizing weight. Finite Element Analysis (FEA) simulations have become invaluable tools in optimizing designs, allowing us to predict stress concentrations and potential failure points before the components are even fabricated. This proactive approach is essential for ensuring the longevity and reliability of the vessel, especially considering the significant safety implications involved in shipbuilding.

Core Functions

- Structural Reinforcement: These bars act as internal supports within the ship's structure for increased mechanical integrity against forces such as wave impact, vibration, and stress distribution.

- Corrosion Resistance: Use of marine grade aluminum significantly reduces the risk of galvanic and crevice corrosion, which is common in saline environments.

- Weight Reduction: Aluminum’s low density allows ships to gain strength without adding excessive weight, increasing fuel efficiency and maneuverability.

- Ease of Fabrication: Excellent machinability allows precise customization of reinforcement parts, saving time and cost during ship construction and maintenance.

Technical Parameters and Standards

The performance of marine grade aluminum solid bars depends heavily on strict compliance with several internationally recognized standards and consistent physical and chemical properties.

Alloy Composition and Chemical Properties

Most commonly used alloys include 5083, 5086, and 6061 series due to their exceptional corrosion resistance and mechanical strength. Below is a typical chemical composition for Alloy 5083, optimized for marine applications:

| Element | Typical Composition (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Copper (Cu) | ≤ 0.1 |

Mechanical Properties (Typical Parameters for 5083-H112)

| Property | Value |

|---|---|

| Tensile Strength | 290 - 350 MPa |

| Yield Strength | ≥ 145 MPa |

| Elongation | ≥ 12% |

| Density | 2.66 g/cm³ |

| Hardness (HB) | 55 - 70 |

Temper Conditioning

Among temper designations for marine aluminum solid bars, H112 and H321 are most prevalent:

- H112 Temper: As-fabricated tempers resulting in specific mechanical properties post rolling or extrusion with minimal additional heat treatment.

- H321 Temper: Strain hardened and stabilized to improve strength and corrosion resistance, particularly beneficial for marine applications.

Implementation Standards for Marine Applications

- ASTM B208 / B221: Defines standard specifications for aluminum alloy rolled and extruded bars, rods, and profiles.

- ABS (American Bureau of Shipping): Provides certification requirements addressing material quality assurance for marine-grade alloys.

- ISO 6361 / 11960: International standards outlining specifications for wrought aluminum sheets, strips, and bars for marine use.

Shipyards and reinforcement applications often require materials that exceed minimal critical values for mechanical parameters and exhibit superior corrosion resistance ratings to fulfill class society certifications.

Distinctive Applications of Marine Grade Aluminum Solid Bars in Shipbuilding

1. Hull Frame Reinforcements

The hull must resist repetitive dynamic loads and corrosion from continuous sea exposure. Marine aluminum solid bars offer rugged support structures that help maintain hull shape without adding unwanted weight.

2. Bulkheads and Deck Fittings

Solid bars machined to specifications are employed in attachment points for bulkheads or tanks, which need stable frameworks resistant to saltwater corrosion as well as cyclic load they impart.

3. Integral Support Structures in Superstructures

Use of lightweight aluminum reinforcements ensures top-heavy ship components maintain strength without compromising vessel stability.

Future Trends and Innovations

Integral tracking of these materials’ behaviors via sensor embedding and real-time monitoring Die Forging techniques contribute towards boosted fatigue resistance and predictability during service life for safer, longer-lasting ship builds.

Related Products

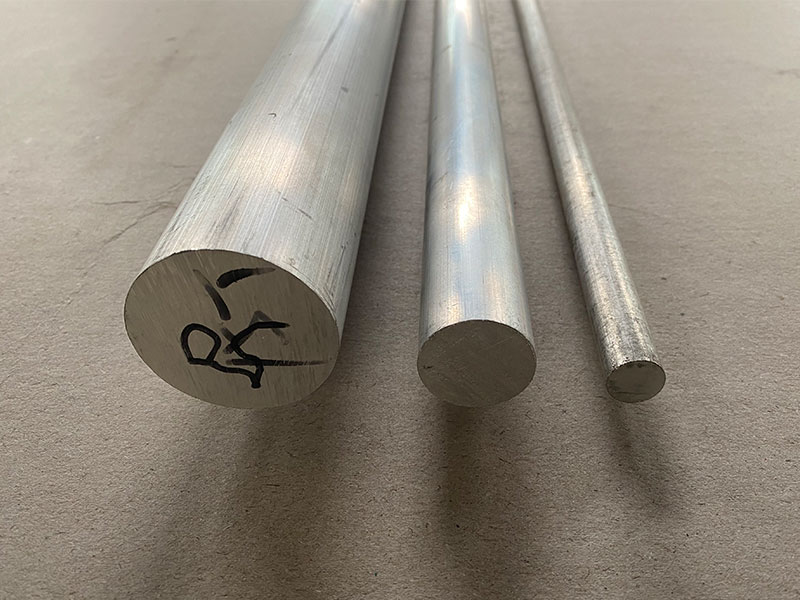

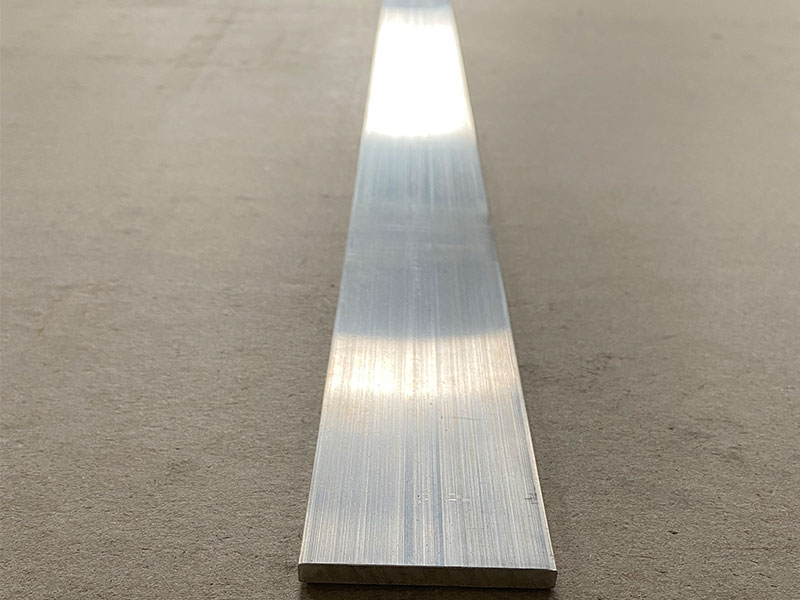

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5052 Marine Grade Aluminum Solid Bar for Saltwater Tolerant Boat Parts

High-performance 5052 marine grade aluminum solid bar, engineered for superior corrosion resistance and durability in saltwater environments. Ideal for boat parts and marine applications demanding long-lasting strength and reliability.

View DetailsMarine Aluminum Hollow Bars for Marine Platform Construction

In the challenging domain of marine platform construction, the choice of materials directly influences the longevity, safety, and performance of offshore installations.

View DetailsMarine Aluminum Hexagonal Bars for Heavy Duty Boat Frame Construction

In the demanding environment of marine construction, selecting the right materials for heavy duty boat frames is crucial. Among the many options, marine aluminum hexagonal bars have emerged as a standout choice, offering an exceptional blend of strength.

View Details6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5083 Marine Grade Aluminum Solid Bar for Boat Hull Reinforcement

In the expansive world of marine construction and engineering, selecting the right materials can make the difference between a resilient vessel and costly structural failures.

View Details

Leave a Message