6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique Applications

When it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, safety, and performance. Among various materials, 6082 marine aluminum hexagonal bars have emerged as a standout solution, combining structural strength, corrosion resistance, and versatile machining capabilities to meet the complex demands of marine environments.

6082 Marine Aluminum: More Than Just an Alloy

6082 aluminum belongs to the 6xxx series, primarily alloyed with magnesium and silicon. This alloy is widely recognized for its superior mechanical properties and corrosion resistance, particularly beneficial for marine applications. Unlike more common marine-grade aluminum alloys such as 5052 or 5083, 6082 strikes an exceptional balance between machinability and tensile strength—traits essential for forming precise, complex offshore components.

The Hexagonal Bar Format: An Engineering Advantage

Hexagonal bars are characterized by their six-sided cross-section, offering benefits over standard round or square bars. In offshore construction, hex bars lend themselves to specific design uses—like fastening, connecting mating parts, or serving as shafts where automated tools benefit from flat surfaces for gripping and torque application. The hexagonal shape also reduces weight without sacrificing core strength, an important factor for reducing structural load on offshore rigs or vessels.

Corrosion Resistance: The Lifeline in Marine Atmospheres

Saline water and harsh weather conditions are notoriously erosive. Why then is 6082 aluminum especially suitable for offshore parts? The alloy forms a natural oxide layer that protects the metal underneath from aggressive chlorides and seawater. With added protective coatings and anodizing, 6082 marine aluminum hex bars extend service life considerably, reducing maintenance costs and downtime.

Applications Across Offshore Marine Construction

The versatility of 6082 marine aluminum hexagonal bars finds multiple industrial uses, such as:

- Structural frames and supports: Hex bars provide robust, lightweight reinforcements that enhance platform safety.

- Fastening elements: Bolts, nuts, and collars machined from hex bars exhibit excellent strength, optimized for bolted joints critical in risers or bracing systems.

- Piping system components: Shapes produced from hex bars assist pipe fittings where torque control is required during installation.

- Marine hardware fittings: Hooks, cleats, and latches made from 6082 offer superior corrosion resistance with the strength to endure repetitive movements and loads offshore.

Distinctive Technical Characteristics From a Production Perspective

Manufacturers favor 6082 marine aluminum hex bars due to:

- Excellent machinability: Reduced tool wear and enhanced finish are achieved thanks to the alloy’s balanced magnesium-silicon content.

- Consistent dimensional tolerance: High accuracy in extrusion and annealing delivers predictable geometric properties ideal for automated manufacturing.

- Heat treatment adaptability: The T6 tempering process improves tensile strength, reaching around 290 MPa, making these hex bars suitable for high-stress offshore zones.

- Welding amenability: 6082 allows effective fusion welding or friction stir welding, promising contiguity in complex assemblies.

Related Products

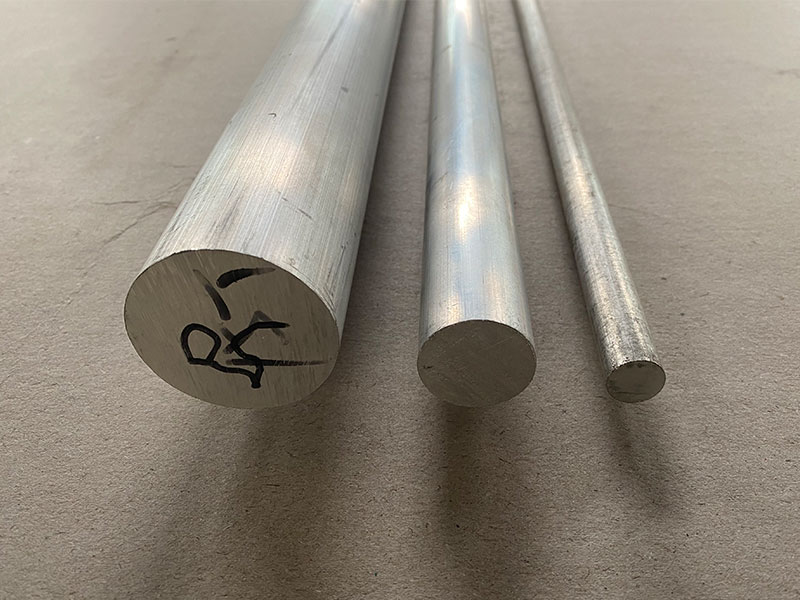

6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details

Leave a Message