Marine 5083 5086 H116 Checkered Aluminum Plate for Deck Board

Marine-grade aluminum alloys have become the material of choice for decking and structural applications on vessels, fight corrosion challenges in saltwater environments, while maintaining superior strength-to-weight ratios. Among these, the Marine 5083 and 5086 aluminum alloys tempered to H116 with a checkered pattern are industry benchmark materials used extensively for ship deck boards, docks, offshore platforms, and other marine structures requiring reliable performance.

What is Marine 5083/5086 H116 Checkered Aluminum Plate?

Alloy Designation: 5083, 5086 (Al-Mg series)

These two alloys belong to the highly corrosion-resistant, non-heat-treatable family of aluminum-magnesium alloys. Both 5083 and 5086 provide an excellent combination of strength, ductility, welding ability, and marine corrosion resistance, making them ideal for harsh marine environments.

Temper: H116

The H116 temper signifies a strain-hardened, stabilized state with very specific conditions optimized to improve stress corrosion cracking resistance while maintaining mechanical strength. It is the stipulated temper for marine-grade aluminium plates intended for hostile environmental exposure.

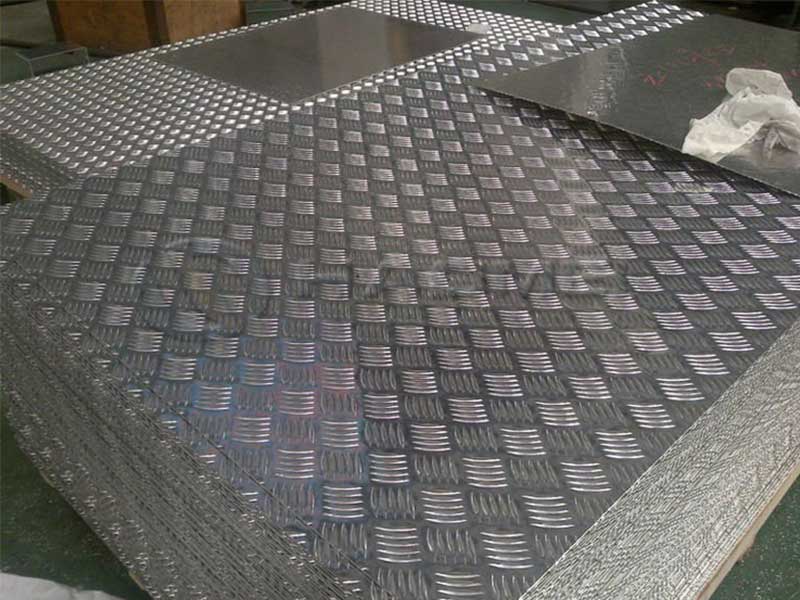

Product Form: Checkered Plate

The aluminum plate is hot rolled then configured with a raised diamond or checkered tread pattern. This patterned surface provides enhanced anti-slip characteristics, critical for decking to maintain footing safety in wet and slick conditions encountered on ship decks or offshore facilities.

Chemical Composition

| Element | 5083 (%) | 5086 (%) |

|---|---|---|

| Aluminum | Bal. | Bal. |

| Magnesium | 4.0 – 4.9 | 4.0 – 4.9 |

| Manganese | 0.4 - 1.0 | 0.2 - 0.5 |

| Iron | ≤ 0.4 | ≤ 0.5 |

| Silicon | ≤ 0.4 | ≤ 0.5 |

| Chromium | 0.05 – 0.25 | 0.05 – 0.25 |

| Copper | ≤ 0.1 | ≤ 0.1 |

| Zinc | ≤ 0.25 | ≤ 0.25 |

Mechanical Properties (Typical for H116 Temper)

| Property | Alloy 5083-H116 | Alloy 5086-H116 | Unit |

|---|---|---|---|

| Yield Strength (0.2% offset) | 215-240 | 215-250 | MPa |

| Tensile Strength | 305-350 | 295-345 | MPa |

| Elongation at Break | ≥12 | ≥10 | % |

| Hardness (Brinell) | ~80-87 | ~85-90 | HB |

| Density | 2.66 | 2.66 | g/cm³ |

Features and Benefits

- High Corrosion Resistance: Both 5083 and 5086 alloys display outstanding resistance to seawater corrosion, including pitting and stress corrosion cracking, a critical factor in marine atmospheres.

- Excellent Mechanical Strength: The alloys maintain a favorable yield and tensile strength that withstand heavy loads and mechanical impact on ship floors.

- Superior Anti-slip Design: The raised checkered pattern imparts safety to wet deck surfaces without sacrificing durability.

- Weldability: Excellent weld strength and compatibility with multiple welding methods (MIG, TIG), allowing fabricators to construct customized layouts.

- Lightweight: Weighing considerably less than steel alternatives, helping reduce vessel weight and improve fuel efficiency.

- Heat and UV Resistance: Retains properties over a broad temperature range and resists degradation by constant ultraviolet exposure.

Implementation and Industry Standards

| Standard | Specification |

|---|---|

| ASTM B928 | Specification for Aluminum-Alloy Rolled Plates, Sheet and Strip for Marine Application |

| AWS D1.2 | Structural Welding Code – Aluminum |

| ISO 6361 | Specifications for Rolled Aluminum 5083 and 5086 |

| US Navy MIL-DTL-46027 | Shipbuilding Grade Specifications for Aluminum Plate |

The plates are offered with full proprietary certifications in chemical and mechanical testing, including thickness check, flatness tolerances, protein-level corrosion tests, and crack determination.

Applications

- Ship & Boat Decks: Enhanced grip and structural strength for passenger and working decks on ferries, yachts, fishing boats, and commercial ships.

- Offshore Platforms: Structural paneling and anti-skid walkways in oil rigs and marine construction.

- Marine Hydraulic Equipment Manufacturing: Durable bases or platforms requiring corrosion-robust surfaces.

- Floating Docks & Pontoons: Ruftop decks or passageways able to withstand prolonged saltwater contact with minimal upkeep.

- Coastal Infrastructure: Bridge walkways, piers, and marina surfaces needing corrosion ideology compliance.

Installation Suggestions and Handling Tips

- Maintain surface cleanliness free of dirt, salt, or coatings detrimental to weld quality.

- Use approved fabrication and joining techniques per AWS and ASTM requirements.

- Avoid overworking or bending which can lead to micro-cracking and reduced corrosion resistance.

- When coating or painting, properly etch and prime according to marine-grade procedures to extend lifespan.

- Store flat and dry to prevent surface oxidation before installation.

Related Products

Marine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsRelated Blog

7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View DetailsMarine Grade Plate Aluminum Sheet 5083 O H116

When it comes to marine construction and offshore applications, selecting the right material is crucial. Marine Grade Aluminum Plate 5083 O H116 stands out as a top-tier solution, blending excellent mechanical properties, corrosion resistance.

View Details5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View Details3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments.

View DetailsMarine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry.

View Details

Leave a Message