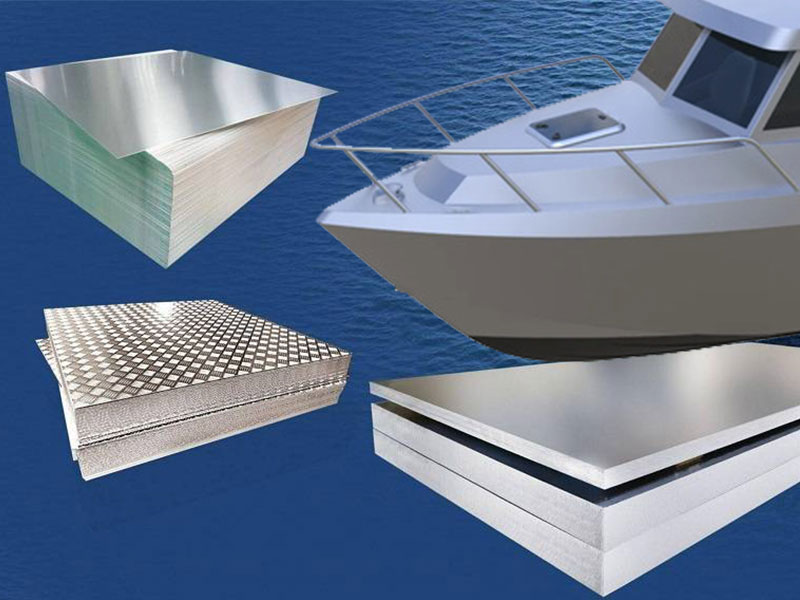

Applications of Marine Aluminum Sheets in Shipbuilding and Superstructures

Marine aluminum sheets have become indispensable materials in modern shipbuilding and superstructure fabrication due to their unique combination of light weight, strength, corrosion resistance, and ease of fabrication. As marine environments subject vessels to severe conditions—such as saltwater corrosion, mechanical stress, and fluctuating temperatures—the selection of construction materials is critical to ensure performance, safety, and longevity.

Why Marine Aluminum Sheets?

Before diving into specific applications, it’s important to recognize why marine aluminum sheets have become a preferred choice in ship construction:

Exceptional Corrosion Resistance: Marine aluminum alloys (primarily 5xxx and 6xxx series such as 5083, 5086, 5052, and 6061) naturally resist seawater corrosion, pitting, and stress corrosion cracking, significantly reducing maintenance and increasing lifespan compared to steel.

Lightweight Yet Strong: With densities roughly one-third that of steel (~2.7 g/cm³ vs. ~7.85 g/cm³), aluminum sheets reduce overall vessel weight, enhancing speed, fuel efficiency, and payload capacity.

Excellent Weldability and Formability: Aluminum’s compatibility with MIG, TIG, and friction stir welding allows complex hull shapes and superstructure components, while its high ductility facilitates bending and forming during fabrication.

Thermal and Acoustic Properties: Aluminum offers good thermal conductivity, aiding heat dissipation, and favorable acoustic characteristics, useful in crew comfort and noise reduction.

Marine Aluminum Alloys Commonly Used

| Alloy | Common Tempers | Characteristics |

|---|---|---|

| 5083 | H111, H321 | High strength and corrosion resistance for hull plating and structural parts |

| 5086 | H32, H34, H116 | Superior corrosion and weldability for structural frameworks and decks |

| 6061 | T6 | High-strength alloy used primarily for superstructure and fittings |

| 5052 | H32 | Good corrosion resistance and formability, often in non-load-bearing panels |

Primary Applications of Marine Aluminum Sheets in Shipbuilding

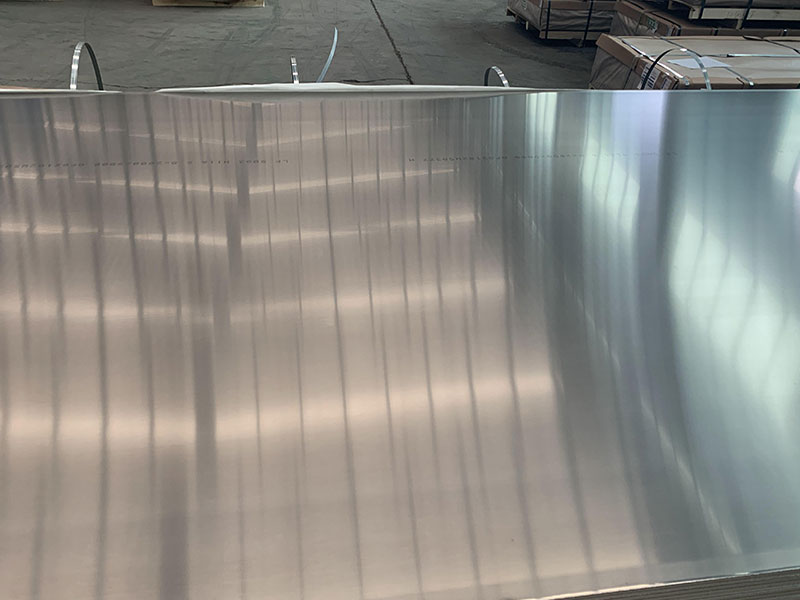

1. Hull Plating

Marine aluminum sheets are extensively used for hull construction in both commercial and recreational vessels. Alloy 5083 and 5086, in particular, offer:

Resistant hull plating that withstands seawater corrosion and impact damage

Weight reduction improving vessel speed and fuel efficiency

Compatibility with large-scale welding and forming processes needed for complex hull geometries

2. Deck and Superstructure Panels

In superstructures—such as cabins, bridges, and deckhouses—aluminum sheets provide:

Structural panels that balance strength and lightweight design

Resistance to corrosion and wear from the marine atmosphere

Flexibility for architectural styling, including curved and contoured surfaces

3. Bulkheads and Internal Framing

Marine aluminum sheets support internal integrity via:

Bulkhead plating providing fire barriers and structural separation

Stiffeners and framing members formed from sheets to reinforce decks and hull sections

Reduced overall weight aiding vessel stability and payload distribution

4. Tanks and Storage Vessels

Aluminum’s inertness and corrosion resistance make it ideal for:

Freshwater, fuel, and wastewater storage tanks fabricated from 5052 or 5083 sheets

Hygienic marine food and chemical processing tanks within vessels

Specialized Marine Superstructure Applications

1. Ladderways, Staircases, and Walkways

Aluminum sheets are fabricated into:

Tread plates and checker plates providing anti-slip surfaces

Structural supports for stairs and walkways offering strength with reduced weight

2. Equipment Enclosures and Housings

Protect sensitive marine machinery and electronics by constructing:

Weather-resistant, corrosion-proof enclosures using aluminum sheets

Sound-insulating panels with aluminum layered composites

3. Railings, Handrails, and Safety Barriers

Aluminum sheets form components that:

Ensure secure, corrosion-resistant guardrails on decks and platforms

Provide lightweight and aesthetically pleasing rail systems

4. Architectural and Decorative Elements

Modern yachts and passenger vessels utilize aluminum sheets for:

Seamless paneling, trim, and decorative features benefiting from anodized or painted finishes

Lightweight facades that withstand marine harshness while enhancing visual appeal

Fabrication and Joining Techniques

Fabricating marine aluminum sheets involves:

Cutting: High-precision shearing, laser, plasma, or waterjet cutting to shape components.

Forming: Cold bending, rolling, and stamping allow complex shapes and curves.

Welding: Advanced techniques, especially TIG, MIG, and friction stir welding, preserve corrosion resistance and structural integrity.

Surface Treatment: Anodizing, powder coating, or marine-grade painting enhance corrosion resistance and aesthetics.

Maintenance and Longevity

Marine aluminum sheets provide a low-maintenance solution but require routine care to maximize lifespan:

Rinse with fresh water regularly to remove salt deposits

Inspect for scratches or mechanical damage, especially in welded areas

Use appropriate cleaning agents to avoid surface degradation

Reapply protective coatings or anodizing over time in aggressive environments

Marine Grade Aluminum Sheets are fundamental to modern shipbuilding and superstructure construction. Their unique blend of corrosion resistance, mechanical strength, light weight, and fabrication versatility delivers superior vessel performance and durability in harsh marine conditions. From hull plating to decorative superstructure elements, marine aluminum sheets enable engineers and shipbuilders to build safer, more efficient, and longer-lasting maritime vessels.

For customized alloy selection, fabrication support, or detailed technical consultation on marine aluminum sheets, please contact our marine metals experts who are committed to supporting your next project’s success.

Related Products

Marine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsRelated Blog

7075 T6 Aluminum Sheet For Boat

When it comes to selecting the ideal material for marine applications, especially boats, durability, corrosion resistance, and strength are non-negotiable. Among various marine-grade aluminum alloys.

View DetailsAluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

View Details10mm 8mm 6mm Marine Aluminium Sheet

In the demanding maritime environment, material performance can decide the lifespan and safety of vessels and related structures. Marine aluminium sheets, particularly in 10mm, 8mm, and 6mm thicknesses, offer a unique combination of durability.

View DetailsMarine grade aluminum for ship building aluminium sheet 5052 h111

Superior strength, corrosion resistance, and durability of marine grade aluminum 5052 H111 aluminum sheets, ideal for shipbuilding applications requiring high fatigue strength and excellent seawater performance.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsMill Finish Aluminium Sheet for Ship building

When it comes to shipbuilding, choosing the right materials is pivotal for ensuring both durability and optimal performance. Among various options, mill finish aluminium sheet stands out as a superior choice.

View Details

Leave a Message