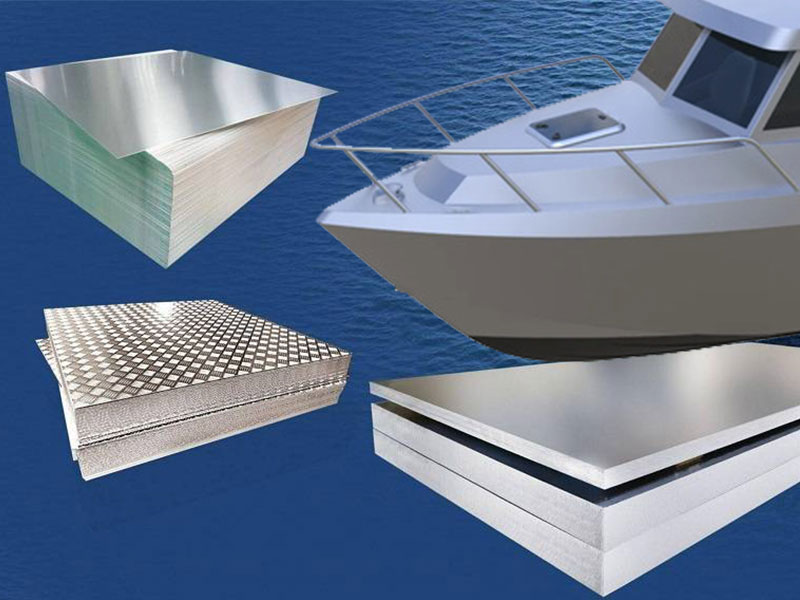

Marine 5086 Aluminum Sheets are high-performance aluminum alloy plates widely used in shipbuilding, offshore structures, and coastal engineering projects where exceptional corrosion resistance, enhanced strength, and excellent weldability are essential. As a member of the 5xxx series aluminum-magnesium alloys, 5086 is specifically engineered to deliver outstanding durability and reliability in harsh marine environments characterized by exposure to seawater, salt spray, and extreme weather conditions.

5086 aluminum is a strain-hardened alloy known for its superior corrosion resistance in seawater and marine atmospheres, which surpasses many other aluminum alloys in this regard. Its magnesium content—slightly higher than 5052—enhances strength and resistance to oxidation, making 5086 particularly suitable for structural marine components that face both mechanical loads and corrosive stresses.

Manufactured via advanced rolling processes, Marine 5086 Aluminum Sheets offer excellent surface quality, dimensional stability, and uniform mechanical properties, facilitating large-scale marine construction and precision fabrication.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Outstanding Corrosion Resistance | Superior resistance to seawater, salt spray, and marine atmospheres due to elevated magnesium content | Prolonged service life and reduced maintenance costs in marine environments |

| Enhanced Mechanical Strength | Higher tensile and yield strength compared to many aluminum alloys in the 5xxx series | Supports structural applications subject to heavy loading |

| Excellent Weldability | Compatible with TIG, MIG, and resistance welding methods without affecting corrosion resistance | Simplifies fabrication and on-site repairs |

| Good Ductility and Formability | Allows bending, rolling, and shaping while maintaining alloy integrity | Enables complex marine component geometries |

| Lightweight | Density approximately 2.66 g/cm³ | Contributes to weight savings and fuel efficiency in vessels |

| Non-Magnetic and Non-Toxic | Safe for marine environments requiring low magnetic interference or chemical inertness | Ideal for specialized marine applications such as electronics enclosure |

Chemical Composition

Below is the typical chemical composition of Marine 5086 Aluminum Sheets, emphasizing its significant magnesium content.

| Element | Typical Range (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.2 – 0.7 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 5086 aluminum sheets are typically supplied in the H32, H34, or H116 tempers, each offering a balance between strength and ductility suitable for marine constructions.

| Property | 5086-H32 | 5086-H34 | 5086-H116 |

|---|---|---|---|

| Tensile Strength (MPa) | 275 - 350 | 295 - 350 | 300 - 360 |

| Yield Strength (MPa) | 145 - 230 | 165 - 240 | 190 - 260 |

| Elongation (%) | 12 - 18 | 10 - 15 | 10 - 14 |

| Brinell Hardness (HB) | 75 - 95 | 80 - 100 | 90 - 105 |

| Density (g/cm³) | 2.66 | 2.66 | 2.66 |

Manufacturing and Available Sizes

Marine 5086 Aluminum Sheets are produced by state-of-the-art hot rolling followed by precise cold finishing to ensure flatness and accurate thickness. Standard stock sheet thicknesses range from 1.5 mm to 12 mm, with widths typically up to 2000 mm. Custom sizing and cutting services are available based on customer requirements.

Surface finishes are typically supplied in mill finish but can be anodized or painted for enhanced corrosion protection or aesthetic purposes.

Corrosion Resistance and Surface Protection

5086 aluminum’s high magnesium and chromium content form a robust oxide layer that significantly improves resistance to pitting, crevice corrosion, and stress corrosion cracking caused by saltwater exposure.

Surface treatments can further improve durability:

Anodizing: Provides a hard, corrosion-resistant, and UV-stable oxide layer.

Powder Coating or Marine-Grade Paint: Adds an additional protective barrier and allows for color customization.

Regular Cleaning: Recommended to remove salt deposits and debris, preserving the protective oxide layer.

Fabrication and Welding Guidelines

Welding: Use appropriate filler materials and controlled heat input to maintain corrosion resistance and mechanical integrity; welded joints maintain most base alloy properties.

Forming: 5086 sheets can be cold bent and formed with care to avoid surface cracking, adhering to recommended bend radii.

Cutting: Suitable for shearing, waterjet, plasma, or laser cutting with proper support to avoid deformation.

Joining: Compatible with marine-grade fasteners such as stainless steel bolts and rivets.

Typical Marine Applications

Ship hull plating and deck sheets

Offshore oil and gas platform structural components

Marine crane and winch base plates

Pontoon hulls and floating structures

Ballast tanks and storage containers

Coastal architectural panels and cladding

Maintenance Recommendations

Regularly wash with fresh water to remove salt residues and contaminants that could accelerate corrosion.

Inspect welded areas periodically for signs of corrosion or mechanical stress.

Avoid contact with dissimilar metals unless proper insulation methods are applied to prevent galvanic corrosion.

Marine 5086 Aluminum Sheets offer a superior combination of corrosion resistance, enhanced strength, excellent weldability, and formability optimized for challenging marine environments. Their robust physical and chemical properties make them an ideal material for durable shipbuilding, offshore construction, and coastal infrastructure projects requiring long-term performance in seawater applications.

We supply Marine 5086 Aluminum Sheets in a wide range of dimensions and tempers tailored to your project needs. For technical support, pricing, or custom fabrication inquiries, please contact our experienced engineering and sales team.