Marine 5383 Aluminum Sheets are high-performance aluminum alloy plates specially engineered for marine and offshore environments. With excellent corrosion resistance, good mechanical strength, and exceptional weldability, 5383 aluminum is widely used in shipbuilding, offshore platforms, and coastal engineering.

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications. Owing to its superior resistance to seawater corrosion and excellent fabricability, 5383 aluminum sheets are extensively utilized in structural components of vessels and offshore facilities operating under harsh saline conditions.

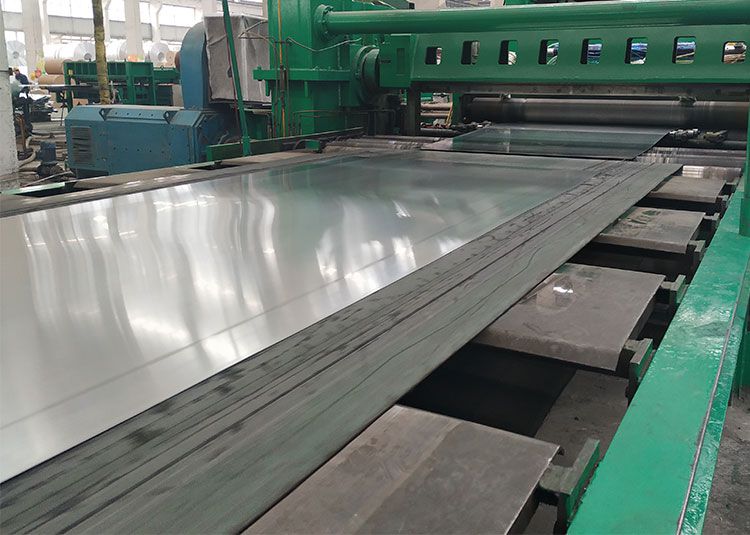

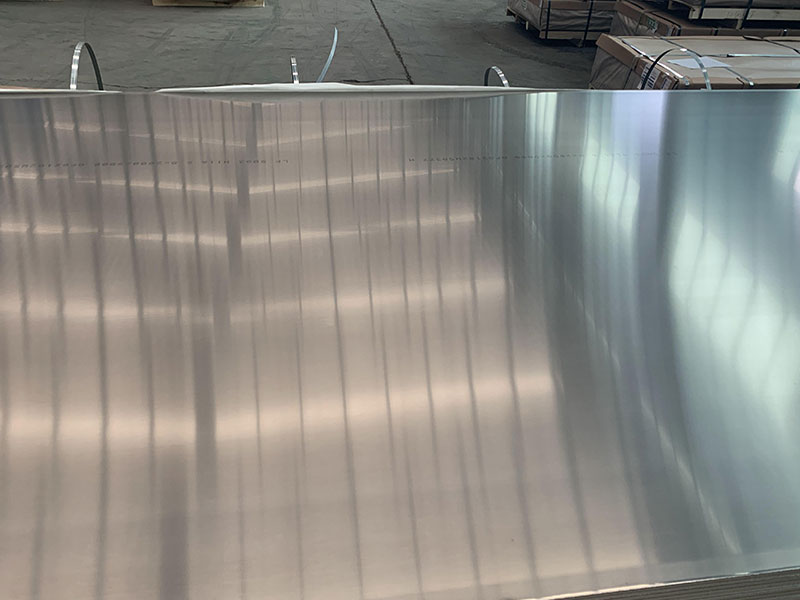

Produced using advanced rolling and finishing processes, Marine 5383 Aluminum Sheets offer outstanding dimensional accuracy, surface quality, and uniform mechanical performance that meet stringent marine standards.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Superior Corrosion Resistance | Enhanced resistance to saltwater, marine atmospheres, and stress corrosion cracking | Improved longevity and lower maintenance in marine settings |

| Good Mechanical Strength | Balanced tensile and yield strength with excellent ductility | Reliable structural performance with increased safety |

| Excellent Weldability | Compatible with TIG/MIG welding, spot welding, and resistance welding processes | Simplifies shipbuilding and offshore fabrication processes |

| High Formability | Easily formed and shaped with minimal risk of cracking or deformation | Enables customization and complex marine component designs |

| Lightweight | Aluminum density ~2.66 g/cm³ | Weight reduction for fuel efficiency and ease of handling |

| Non-Magnetic and Eco-Friendly | Aluminum’s natural properties make it safe for sensitive applications and environmentally sustainable | Ideal for electronic equipment housings and green construction |

Chemical Composition

The chemical composition of Marine 5383 Aluminum Sheets reflects an optimized formulation for marine endurance and structural strength:

| Element | Typical Range (%) |

|---|---|

| Magnesium (Mg) | 4.5 – 5.5 |

| Manganese (Mn) | 0.2 – 0.7 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.3 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.1 |

| Aluminum (Al) | Balance |

Mechanical Properties

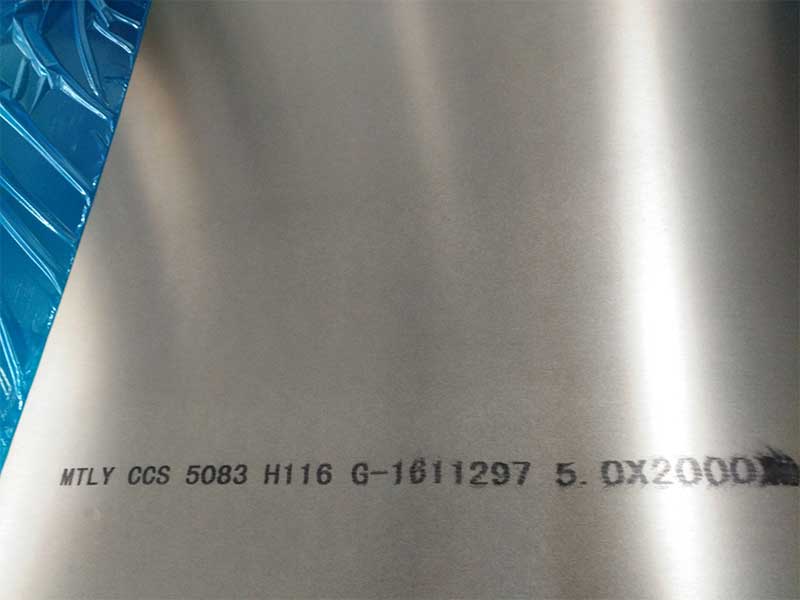

Marine 5383 aluminum sheets exhibit mechanical strengths suitable for structural marine applications, typically supplied in tempers H32, H112, or H116.

| Property | 5383-H32 | 5383-H112 | 5383-H116 |

|---|---|---|---|

| Tensile Strength (MPa) | 300 – 360 | 310 – 370 | 320 – 380 |

| Yield Strength (MPa) | 180 – 260 | 190 – 270 | 205 – 290 |

| Elongation (%) | 10 – 15 | 10 – 14 | 10 – 13 |

| Brinell Hardness (HB) | 75 – 95 | 80 – 100 | 85 – 105 |

| Density (g/cm³) | 2.66 | 2.66 | 2.66 |

Manufacturing and Available Sizes

Marine 5383 Aluminum Sheets are produced through advanced hot rolling and finishing techniques that guarantee precise thickness control, flatness, and surface finish quality. Thickness options commonly range from 1.5 mm to 12 mm, with standard widths up to 2000 mm. Custom sizes and cutting services are also available to meet specific marine project requirements.

Sheets typically come with a smooth mill finish but can be anodized, powder-coated, or painted to enhance corrosion resistance and aesthetics.

Corrosion Resistance and Surface Protection

The naturally formed thin oxide film of 5383 aluminum alloy effectively protects it from corrosion in marine environments, including resistance to pitting and stress corrosion cracking. Additional surface treatments may be used for enhanced protection and decorative purposes:

Anodizing: Thickens the oxide layer for improved abrasion and corrosion resistance with optional color finishes.

Powder Coating or Marine Paint: Provides a durable barrier against harsh weather and UV exposure.

Regular Maintenance: Freshwater rinsing to remove salt deposits and deposits extends service life.

Fabrication Guidelines

Welding: Employ recommended filler metals and welding procedures for 5xxx series aluminum alloys to maintain corrosion resistance and mechanical properties.

Cutting: Suitable for CNC, plasma, laser, or water jet cutting, minimizing burrs and distortion.

Forming: Cold forming and bending possible with appropriate tooling and adherence to minimum bending radii.

Joining: Mechanical fastening with corrosion-resistant fasteners is compatible.

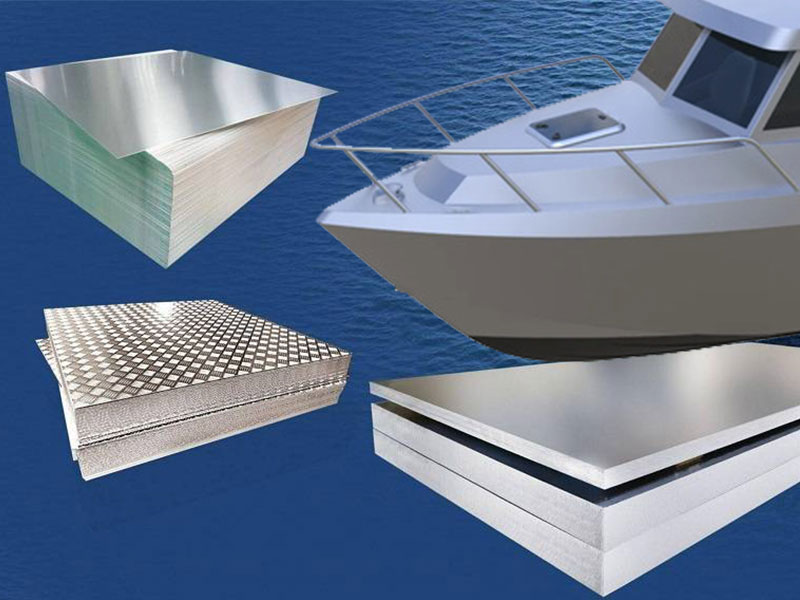

Typical Marine Applications

Hull plating and deck structures on ships and commercial vessels

Offshore platform structural components and walkways

Bulkheads, fuel and water tanks

Coastal building cladding and infrastructure components

Boat cabin walls, flooring, and trim panels

Marine equipment enclosures and housings

Maintenance Recommendations

Marine 5383 Aluminum Sheets offer low maintenance requirements due to their excellent corrosion resistance. Best practices include:

Periodic washing with fresh water to eliminate salt residue.

Avoidance of harsh chemicals or abrasive cleaning tools.

Inspection of welded joints and fastened areas for early signs of corrosion or damage.

With its excellent corrosion resistance, high mechanical strength, and ease of fabrication, Marine 5383 Aluminum Sheets provide an effective solution for a variety of marine and offshore structural applications. The alloy’s superior performance in seawater environments coupled with its lightweight nature make it a preferred choice among shipbuilders and marine engineers aiming for long-lasting, reliable marine structures.

We provide Marine 5383 Aluminum Sheets in customizable sizes, thicknesses, and tempers tailored to your project needs. For detailed specifications, technical consultation, and quotations, please contact our dedicated sales and engineering team.