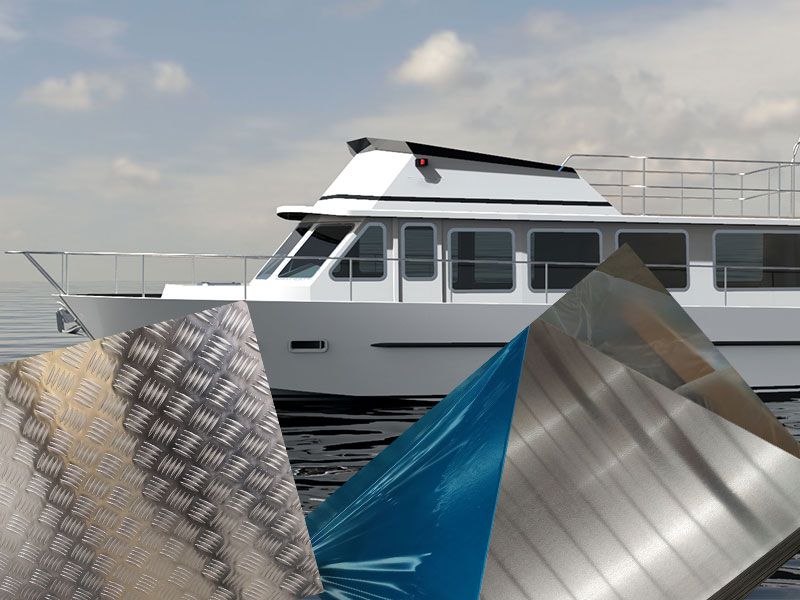

Marine 5083 Aluminum Sheets are premium-grade aluminum alloy plates specifically engineered for the harsh conditions of marine and offshore environments. Widely recognized for their superior corrosion resistance, high strength-to-weight ratio, and excellent weldability, 5083 aluminum sheets serve as a reliable and durable solution for shipbuilding, offshore platforms, and coastal infrastructure.

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres. Its exceptional resistance to marine corrosion and excellent formability have made 5083 a material of choice for structural and non-structural marine applications where longevity and safety are priorities.

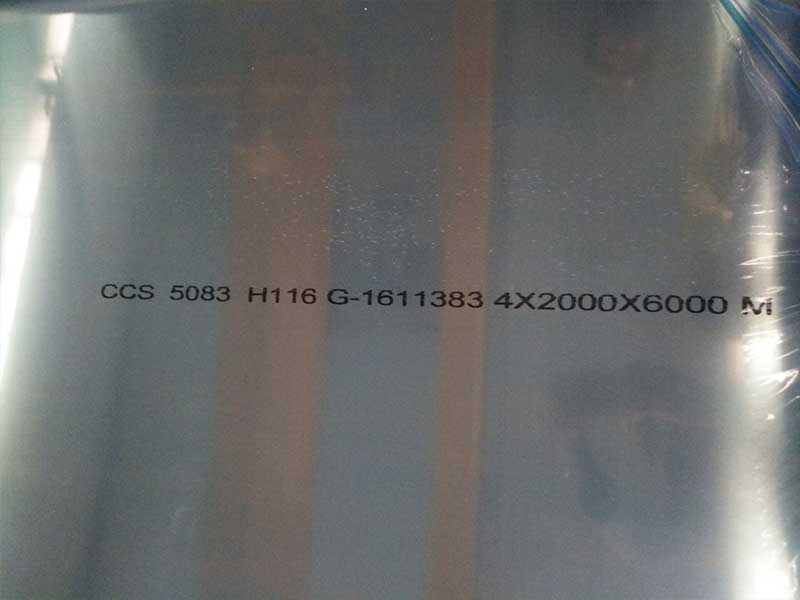

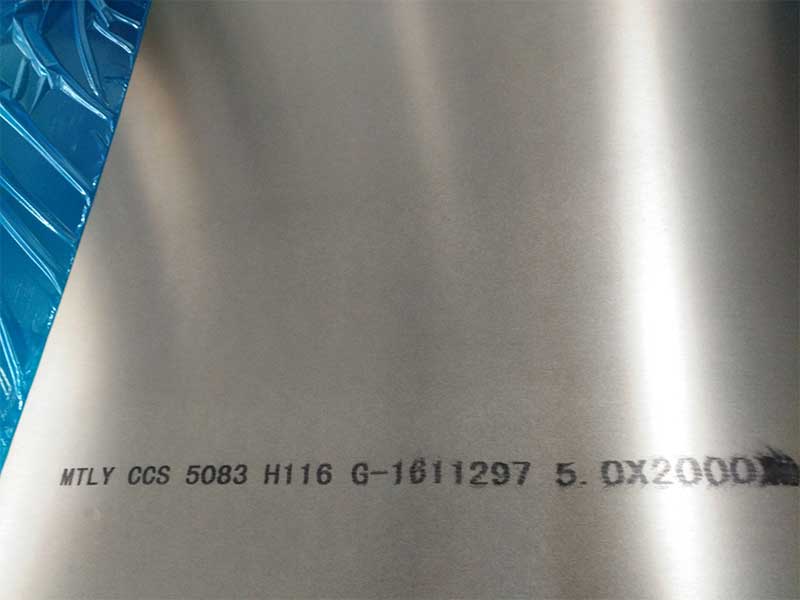

Marine 5083 Aluminum Sheets are manufactured through advanced rolling processes to achieve precise dimensional tolerances and superior surface quality. These sheets can be supplied in various thicknesses and sizes to support diverse marine construction and fabrication needs.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Superior Corrosion Resistance | Exceptional resistance to saltwater, seawater spray, and marine atmospheres due to magnesium content | Extended service life even in aggressive marine environments |

| High Mechanical Strength | Strong structural performance while maintaining relatively low weight | Provides reliable load-bearing capacity with weight savings |

| Excellent Weldability | Compatible with common welding methods (TIG, MIG, resistance welding) without compromising integrity | Facilitates fabrication and repair on-site |

| Good Formability and Workability | Can be easily bent, formed, and shaped without cracking or deformation | Flexibility for custom marine designs |

| Lightweight | Density approximately 2.66 g/cm³ | Reduces overall vessel weight, improving fuel efficiency |

| Non-Magnetic | Aluminium’s non-ferrous nature makes it ideal for electronic and sensitive marine equipment | Minimizes interference and magnetic signatures |

| High Impact Resistance | Maintains toughness and ductility at low temperatures | Improved safety and durability under mechanical stress |

Chemical Composition

The chemical makeup of 5083 aluminum highlights its high magnesium content essential for marine corrosion resistance.

| Element | Content Range (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Remainder |

Mechanical Properties

The mechanical characteristics of 5083 aluminum sheets can vary depending on temper and processing. Below are typical values for the commonly used temper H111 and H321, suitable for marine applications:

| Property | 5083-H111 | 5083-H321 |

|---|---|---|

| Tensile Strength (MPa) | 275 - 345 | 300 - 350 |

| Yield Strength (MPa) | 125 - 215 | 145 - 215 |

| Elongation (%) | 12 - 24 | 10 - 18 |

| Brinell Hardness (HB) | 70 - 95 | 75 - 95 |

| Density (g/cm³) | 2.66 | 2.66 |

Manufacturing and Sizes

Marine 5083 Aluminum Sheets are produced primarily by hot rolling with stringent quality control to ensure flatness, thickness accuracy, and surface finish. Available thickness typically ranges from 1.5 mm to 20 mm or more, with standard widths up to 2000 mm. Custom sizes can be produced on request.

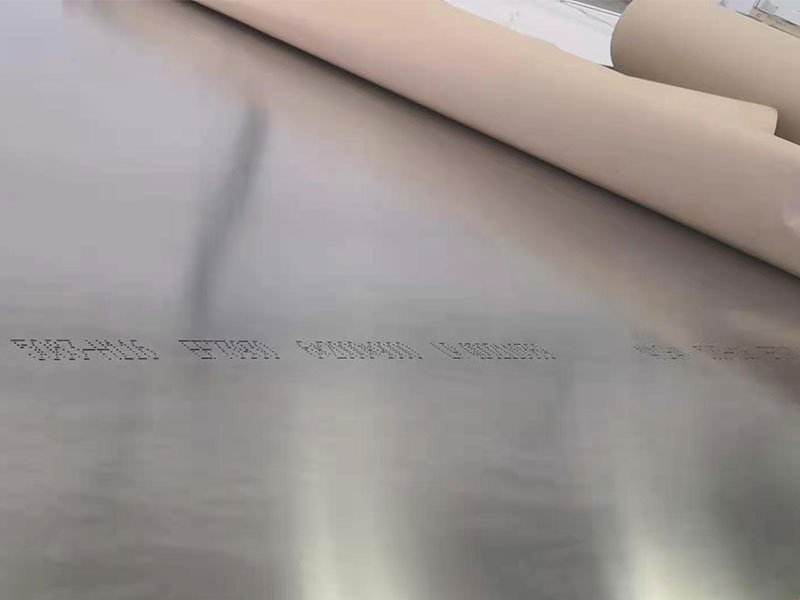

Sheets usually feature a smooth mill finish, although surface treatment options such as anodizing or painting are also available for enhanced protection or aesthetic purposes.

Typical Marine Applications

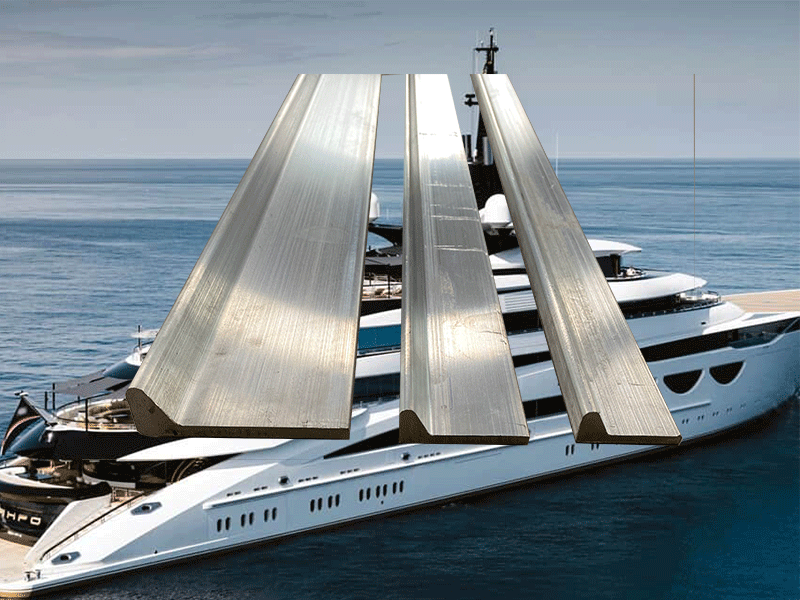

Shipbuilding: Hull plating, bulkheads, decks, and superstructures

Offshore Platforms: Structural members, walkways, staircases, and safety railings

Boat Manufacturing: Hulls, decks, and cabins for yachts and commercial vessels

Marine Equipment: Pump housings, transport containers, and storage tanks

Coastal and Port Infrastructure: Marine bridges, piers, mooring platforms, and storage facilities

Corrosion Resistance and Maintenance

The high magnesium content in 5083 aluminum enhances resistance to seawater corrosion including pitting and stress corrosion cracking. Nevertheless, periodic maintenance improves longevity:

Cleaning: Regular rinsing with fresh water to remove salt residues and contaminants

Inspection: Routine visual checks for signs of corrosion or mechanical damage

Surface Protection: Optional anodizing or application of marine-grade coatings for extra protection

Due to its inherent corrosion resistance, 5083 aluminum requires less maintenance than conventional steels and many other metals.

Fabrication Recommendations

Welding: Follow appropriate procedures for 5xxx series aluminum, with controlled heat input to avoid distortion and loss of mechanical properties

Cutting: Can be cut by shearing, CNC machining, water jet, or laser cutting without leaving burrs or causing surface cracks

Forming: Suitable for cold bending and shaping, but follow recommended minimum bend radii to prevent cracking

Joining: Bolting and riveting with marine-grade fasteners are recommended for assemblies where disassembly may be required

Marine 5083 Aluminum Sheets combine lightweight strength, exceptional corrosion resistance, and excellent weldability to offer an ideal material solution for critical marine and offshore applications. Their robust mechanical properties and ability to withstand harsh saline environments with minimal maintenance make them a preferred choice for shipbuilders, offshore engineers, and marine fabricators worldwide.

We supply Marine 5083 Aluminum Sheets to meet your customized size, thickness, and temper specifications. For technical support, pricing, and delivery schedules, please contact our sales engineering department.