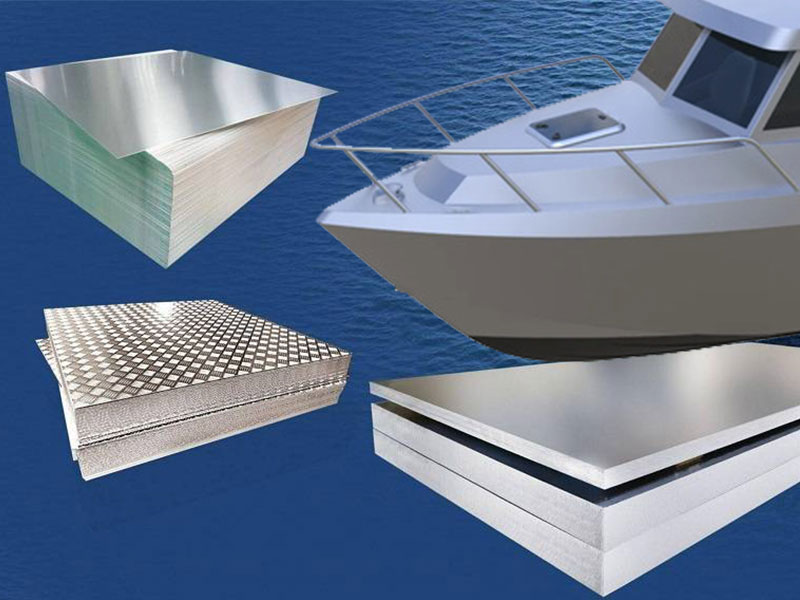

Marine 5052 Aluminum Sheets are premium-grade aluminum alloy sheets specifically formulated for marine and offshore applications requiring outstanding corrosion resistance, excellent formability, and good mechanical strength. Renowned for their enhanced resistance to seawater and salt spray, 5052 aluminum sheets are widely used in shipbuilding, boat manufacturing, offshore platforms, and coastal infrastructure.

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

Marine 5052 Aluminum Sheets are manufactured through precision rolling and finishing processes that ensure consistent thickness, dimensions, and surface quality. These sheets are available in various thicknesses, widths, and lengths to accommodate diverse marine fabrication requirements.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Excellent Corrosion Resistance | High resistance to seawater, marine atmospheres, and salt spray due to magnesium content | Long-lasting protection against rust and saltwater damage |

| Superior Formability | Outstanding bending, rolling, and shaping capability without cracking or loss of strength | Enables complex marine component fabrication and design flexibility |

| Good Mechanical Strength | Balanced tensile and yield strength suitable for structural and non-structural marine parts | Reliable performance under mechanical stresses |

| Weldable | Compatible with SMAW, MIG, TIG welding processes with proper techniques | Facilitates easy assembly and repair on marine vessels and structures |

| Lightweight | Low density (~2.68 g/cm³) resulting in reduced overall weight | Improves fuel efficiency and simplifies handling |

| Non-Magnetic and Non-Toxic | Ideal for environmentally sensitive marine equipment and applications | Safe for food processing and medical marine applications |

| Good Fatigue Resistance | Maintains integrity under cyclic loading | Suitable for dynamic structural components |

Chemical Composition

Marine 5052 aluminum is primarily alloyed with magnesium and small amounts of chromium to improve corrosion resistance and strength.

| Element | Content Range (%) |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Copper (Cu) | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.03 |

| Aluminum (Al) | Remainder |

Mechanical Properties

The mechanical properties of 5052 aluminum sheets can vary based on temper. The most common tempers for marine applications are H32 and H34 due to their good balance of strength and formability.

| Property | 5052-H32 | 5052-H34 |

|---|---|---|

| Tensile Strength (MPa) | 228 - 271 | 229 - 272 |

| Yield Strength (MPa) | 103 - 138 | 117 - 155 |

| Elongation (%) | 10 - 15 | 8 - 10 |

| Hardness (Brinell) | 60 - 75 | 70 - 80 |

| Density (g/cm³) | 2.68 | 2.68 |

Manufacturing and Sizes

Marine 5052 Aluminum Sheets are produced using hot rolling techniques with stringent quality control to ensure dimensional accuracy, flatness, and surface integrity. These sheets are available in thickness ranges from 0.5 mm to 10 mm or thicker, depending on project requirements. Standard widths typically range from 1000 mm to 2000 mm, with custom lengths available.

Surface finishes include mill (natural) finish and optional anodizing or painting for enhanced corrosion protection and aesthetics.

Typical Applications

Shipbuilding: Deck panels, fuel tanks, bulkheads, and hull plating in non-structural areas

Boat Manufacturing: Cabin panels, flooring, and interior partitioning

Offshore Platforms: Walkways, handrails, storage containers, and platform coverings

Coastal Infrastructure: Decorative cladding, signage, and lightweight building components

Marine Equipment: Pump housings, marine transportation containers, and tanks

Food and Chemical Processing: Due to its non-toxic and non-magnetic qualities

Corrosion Resistance and Maintenance

5052 aluminum sheets are renowned for their outstanding resistance to corrosion in seawater and marine atmospheres. This resistance is enhanced by the magnesium content and the natural formation of a protective oxide film on the aluminum surface.

Maintenance Tips:

Rinse regularly with fresh water to remove salt deposits and prevent surface degradation.

Avoid abrasive cleaners or harsh chemicals that could damage the oxide layer.

Inspect for scratches or mechanical damage that may expose the base metal and consider re-coating or anodizing if necessary.

Overall, 5052 aluminum requires minimal maintenance compared to traditional steel and offers superior longevity in marine environments.

Fabrication Recommendations

Welding: Use proper welding procedures suitable for 5xxx series aluminum; preheating is generally not required, but post-weld heat treatment is not recommended.

Cutting: Compatible with laser, water jet, plasma, or mechanical cutting; clean cuts reduce the need for secondary finishing.

Forming: Excellent cold-forming capabilities; avoid over-bending that might cause cracking.

Joining: Compatible with mechanical fasteners, including marine-grade stainless steel bolts and rivets.

Marine 5052 Aluminum Sheets provide an excellent balance of corrosion resistance, formability, and mechanical strength tailored for demanding marine environments. Their lightweight, non-magnetic nature combined with superior resistance to seawater corrosion make them an ideal alloy choice for a wide array of marine applications ranging from shipbuilding to offshore platforms.

Marine 5052 Aluminum Sheets are available in custom sizes, thicknesses, and tempers to meet your project-specific needs. For expert technical consultation, pricing, and delivery information, please contact our sales and engineering teams.