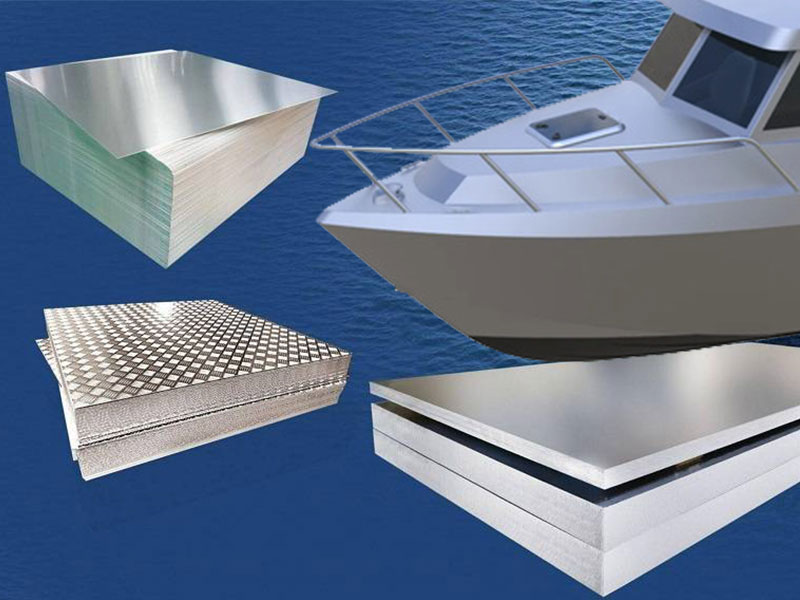

Marine Aluminum Tread Sheets are high-performance aluminum alloy plates designed specifically for demanding maritime environments. Known for their outstanding corrosion resistance, mechanical strength, and anti-slip surface, these sheets are ideal for various marine applications, including shipbuilding, docks, platforms, and walkways. Combining durability with lightweight characteristics, marine aluminum tread sheets offer an efficient and long-lasting solution to meet the stringent requirements of marine industries.

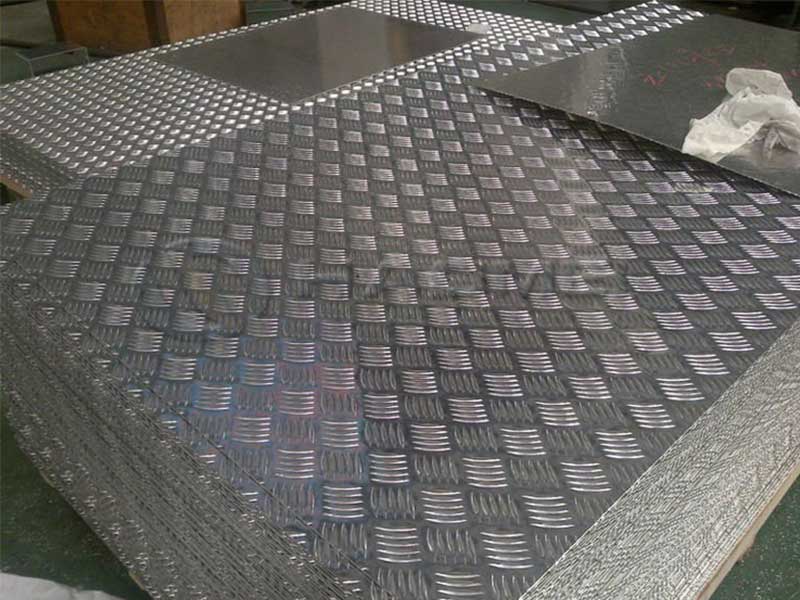

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate. This textured surface not only enhances the sheet’s slip resistance but also provides increased rigidity without significantly adding weight. These properties make them invaluable for safety-critical walking and working surfaces aboard vessels and offshore installations.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Alloy | Typically made from alloy series 5000 or 6000, such as 5083 and 6061, both renowned for corrosion resistance | Superior resistance to saltwater corrosion |

| Anti-Slip Surface | Raised tread patterns (diamond or linear) provide excellent grip under wet or oily conditions | Enhanced safety for crew and passengers |

| Lightweight | Aluminum’s low density (approximately 2.7 g/cm³) helps reduce overall vessel weight | Improved fuel efficiency and easier handling |

| High Strength | Mechanical properties suitable for structural applications | Reliable performance under mechanical stress |

| Excellent Weldability | Compatible with common aluminum welding techniques | Easy integration into ship structures |

| Low Maintenance | Resistant to rust and marine oxidation | Reduced life-cycle costs |

Typical Applications

Deck coverings on ships, ferries, and yachts

Gangways and loading ramps

Offshore platforms and oil rigs

Fish processing plants and marine food industries

Boat flooring and custom marine fabrication

Walkways, stair treads, and ramps

Chemical Composition

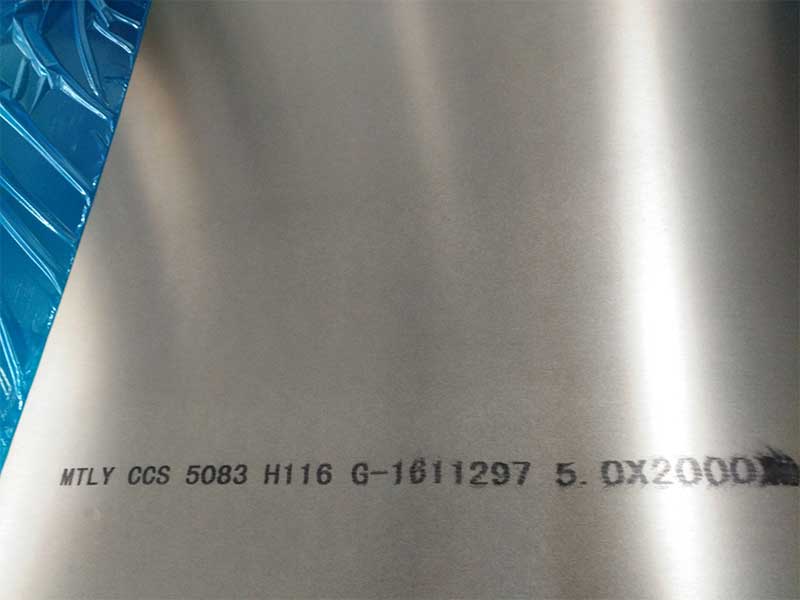

Marine aluminum tread sheets are produced primarily from alloys that maintain strength and corrosion resistance in harsh saltspray conditions. Below is a typical chemical composition for two commonly used marine-grade alloys:

Table 1: Chemical Composition (%) of Marine Aluminum Alloys

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | Remainder |

Mechanical Properties

Mechanical strength varies slightly based on temper and alloy. Below are representative values for these marine-grade alloys:

Table 2: Mechanical Properties of Marine Aluminum Tread Sheets

| Property | 5083-H321 | 6061-T6 |

|---|---|---|

| Tensile Strength (MPa) | 290-350 | 310-350 |

| Yield Strength (MPa) | 145-215 | 260-290 |

| Elongation (%) | 10-18 | 8-12 |

| Hardness (Brinell) | 75-95 | 95-115 |

| Density (g/cm³) | 2.66 | 2.70 |

Manufacturing and Surface Patterns

Marine aluminum tread sheets can be custom-fabricated to different thicknesses and sizes. Standard thickness ranges from 1.5 mm up to 6 mm or more, depending on application requirements. Common tread patterns include:

Diamond Plate: Raised diamond shapes for maximum grip and aesthetic appeal.

Linear/Checkered Pattern: Parallel raised ridges for directional skid resistance.

The sheets are manufactured by hot rolling or cold rolling techniques followed by pattern embossing to create the textured surface.

Corrosion Resistance and Maintenance

The marine environment is highly corrosive due to constant exposure to saltwater and weather conditions. Aluminum alloys like 5083 and 6061 are specifically selected for marine tread sheets because they form a protective oxide layer that prevents deep corrosion. Additionally:

Periodic cleaning with fresh water will extend the service life.

Surface treatments such as anodizing or painting can provide additional protection and aesthetics.

Repair and welding can be carried out on-site without compromising corrosion resistance.

Ordering Information

Customers can specify:

Alloy type (5083, 6061, etc.)

Thickness and sheet dimensions

Temper and mechanical grades

Tread pattern type

Surface finish requirements

We provide custom cutting, drilling, and fabrication services to meet tight project specifications.