10mm 8mm 6mm Marine Aluminium Sheet

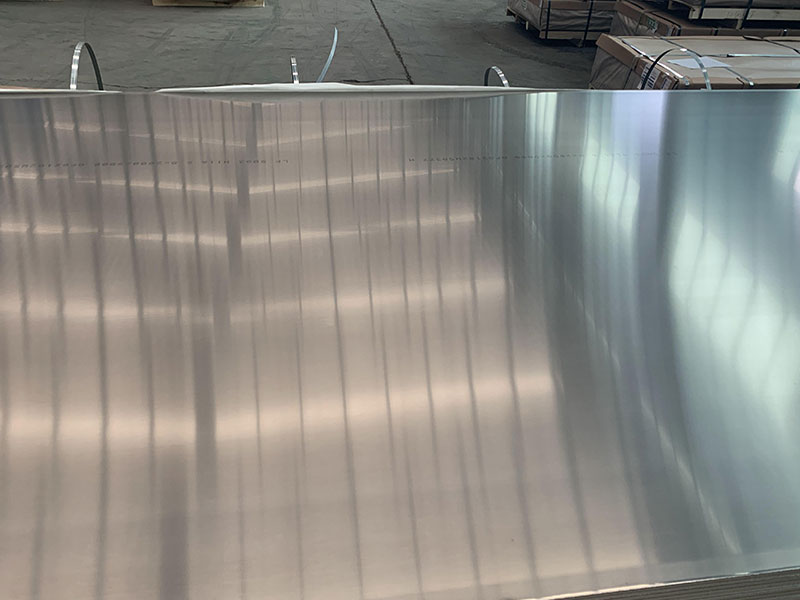

In the demanding maritime environment, material performance can decide the lifespan and safety of vessels and related structures. Marine aluminium sheets, particularly in 10mm, 8mm, and 6mm thicknesses, offer a unique combination of durability, corrosion resistance, and strength.

1. The Role of Thickness: Why 10mm, 8mm, and 6mm Matter

When selecting marine aluminium sheets, thickness isn’t just a dimension — it’s a function-defining parameter. Each thickness suits particular applications:

Working with 10mm, 8mm, and 6mm marine aluminum sheets daily reveals some interesting nuances. The thicker 10mm sheets are undeniably robust, ideal for applications demanding high strength and resistance to impact, like the hulls of larger boats or heavy-duty equipment housings. However, their increased thickness presents challenges in fabrication; cutting and bending require more powerful machinery and careful planning to avoid warping or cracking. We often find that while the initial cost is higher, the longevity and reduced maintenance needs over the lifespan of the final product offset this. The lighter 6mm sheet, on the other hand, is much more versatile and easier to manipulate, making it popular for smaller boat components or decorative elements where weight is a significant factor. Balancing strength and workability is key, and we often advise clients on the optimal thickness depending on their specific application and budget.

One recurring issue we've observed is the importance of proper surface preparation before welding or joining these sheets. Even minor surface imperfections can lead to weld defects or premature corrosion, especially in the harsh marine environment. Our rigorous quality control involves meticulous cleaning and surface treatment to ensure optimal adhesion and longevity. Furthermore, the choice of alloy within the "marine aluminum" designation is crucial. While 5083 and 5052 are common choices, their properties differ slightly in terms of strength and corrosion resistance. We've seen instances where using the wrong alloy

- 10mm Sheets: Provide enhanced strength for structural hull plating, bulkheads, and decking where high mechanical loads, impact resistance, and dimensional stability over time are essential.

- 8mm Sheets: Serve in mid-load areas such as superstructures, deck beams, and framing, striking a balance between weight savings and performance.

- 6mm Sheets: Ideal for components requiring greater flexibility and minimum weight penalty without sacrificing resistance to corrosive seawater—such as small boat hulls, marine gear casings, and auxiliary components.

2. Technical Foundations: Assessing Alloy Groups, Standards & Tempering

Marine Aluminium Alloy Types

Marine aluminium sheets commonly originate from the 5xxx series alloys, especially 5052, 5083, and 5086, prized for their outstanding corrosion resistance in saltwater environments while maintaining formidable strength. Occasionally, 5xxx series offers variants with slight tweaks suiting certain fabrication steps like welding.

Temper Designations and Mechanical Properties

Temper refers to the treatment process the aluminium sheet has undergone to optimize its strength and workability:

- H32 Temper: Strain-hardened then stabilized for marine alloys—this is a popular option reflecting a strong balance: altered mechanical properties for better formability during fabrication with good results under static and dynamic loads.

- H34 Temper: Similar to H32 but with greater strain-hardening, ideal for areas requiring more structural reinforcement without alloy roll overs.

- O (Annealed): Fully annealed aluminium offering excellent ductility for shaping and welding, trading off some tensile strength present in work-hardened conditions.

Marine aluminium sheets in these typical thicknesses come treated to conform to recognized marine standards such as ISO 17083 and ABS (American Bureau of Shipping) Type Approval, ensuring compatibility with maritime design codes and classification societies.

A detailed of the chemical makeup lays the foundation for consistent marine performance. Below is the typical composition range for a commonly used marine marine aluminium alloy, 5083, per common standards from ASTM B209 / AA and JIS H 4100 against targets for sustained corrosion resistance:

| Element | % Weight Range |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Others | 0.05 per element max |

| Aluminium (Al) | Balance |

These percentages optimize corrosion resistance, weldability, mechanical strength, and impact resistance — all paramount in seafaring applications.

4. Functional Advantages in Maritime Environments

Beyond dimensional characteristics, marine aluminium sheets of 6mm-10mm thickness demonstrate capabilities critical for endurance in saline atmospheres:

- Superior Corrosion Resistance: Thanks to alloying Mg (magnesium) and Cr, these sheets form a stabilizing oxide layer resistant to salt spray, sea air, and moisture.

- Lightweight Yet Resilient: These alloys minimize vessel weight without sacrificing necessary hull strength, enabling higher fuel economy and superior stability.

- Weldability and Workability: The temper and alloy combinations strikebalance efficiencies, allowing formers and fabricators to laser cut, bend, and weld while complying with maritime construction standards.

- Fatigue Resistance: Sections made with 6-10mm sheets withstand cyclic mechanical stresses from waves and hull flexing, mitigating fatigue cracks typical in other materials.

5. Real-World Applications of Marine Aluminium Sheets (6mm-10mm)

Whether it's a small yachts’ cabin frame or large commercial marine vessels, these sheets find widespread application:

- Structural Hull Plates (10mm): Their thickness resists extensive hull pressures and puncture forces, safeguarding the vessel's integrity through harsh weather and collisions.

- Deck and Bulkheads (8mm): Employed for substructures and framing to weigh lesser yet retain anatomic sturdiness—aided by enhanced prevention properties against corrosion and aging.

- Marine Equipment Casings & Panels (6mm): Lightweight parts such as instrument housings, hatch covers, and masts benefit from non-magnesium induced corrosion–safe aesthetics and durability.

- Corrosion Shields & Cladding Layers: Marine aluminium sheets bolster vessel endurance with heat- and salt-tolerant conductive material lamination.

Choosing between 6mm, 8mm, and 10mm marine aluminium sheets is less a matter of mere thickness, but precision application-driven decisionmaking built on thorough technical :

- Identify your load, safety, and fabrication scheme priorities.

- Consider alloy chemistry for combined mechanical strength and corrosion resistance.

- Match temper treatments according to the balance needed for manufacturing and end-use requirements.

- Verify marine-compliant standards to ensure industry-accepted lifetime durability.

Only then can marine aluminium sheets truly unlock their promised intelligence at once cost-effective, highly resilient, and aligned with progressive maritime engineering demands.

Optimized for builders, marine fabricators, and specification engineers, this explorative overview unites material science fundamentals with pragmatic design application angles—establishing 10mm, 8mm, and 6mm marine aluminium sheets as essential pillars in modern maritime constructions.

Related Products

Marine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

0.3mm 0.4mm 0.5mm 1.6mm Thickness Roll Aluminium Coil Sheet 5052 h32 For Boat

When it comes to marine applications, selecting the right material is crucial for performance, durability, and safety. Enter the 5052 H32 marine aluminum coil sheet, available in thicknesses ranging from 0.

View DetailsMarine aluminium alloy sheet

Marine aluminum alloy sheet is an indispensable material in the construction and maintenance of vessels, offshore platforms, and various marine infrastructure. Its unique combination of strength, corrosion resistance.

View DetailsMill Finish Aluminium Sheet for Ship building

When it comes to shipbuilding, choosing the right materials is pivotal for ensuring both durability and optimal performance. Among various options, mill finish aluminium sheet stands out as a superior choice.

View DetailsMarin grade aluminum sheet 5052 5mm thick for boat

What is Marine Grade Aluminum 5052?Aluminum 5052 is a non-heat-treatable aluminum-magnesium alloy primarily known for excellent corrosion resistance, high strength among the non-heat treatable grades, and superb weldability.

View Details5754 marine grade aluminium alloy sheet

Comprehensive capabilities and technical specifications of 5754 marine grade aluminium alloy sheets. Ideal for marine applications, this alloy offers excellent corrosion resistance, superb weldability, and robust mechanical properties, ensuring durability

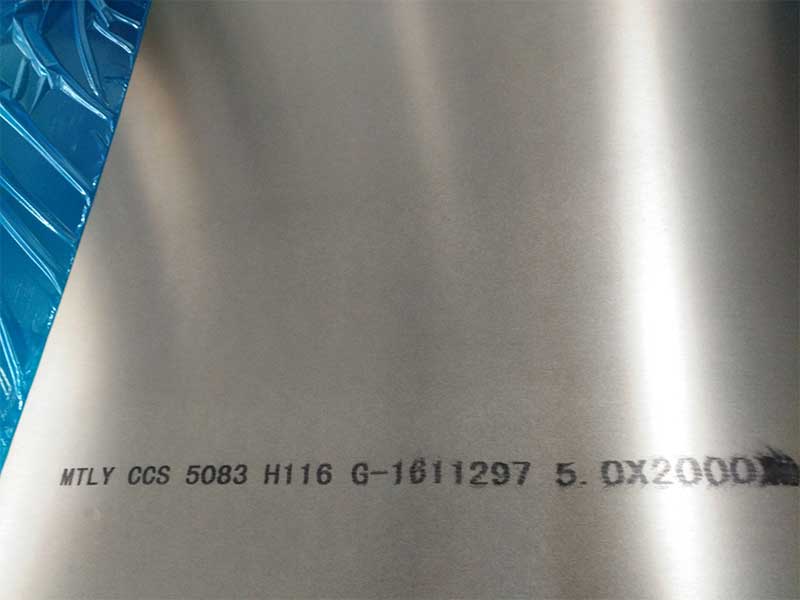

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details

Leave a Message