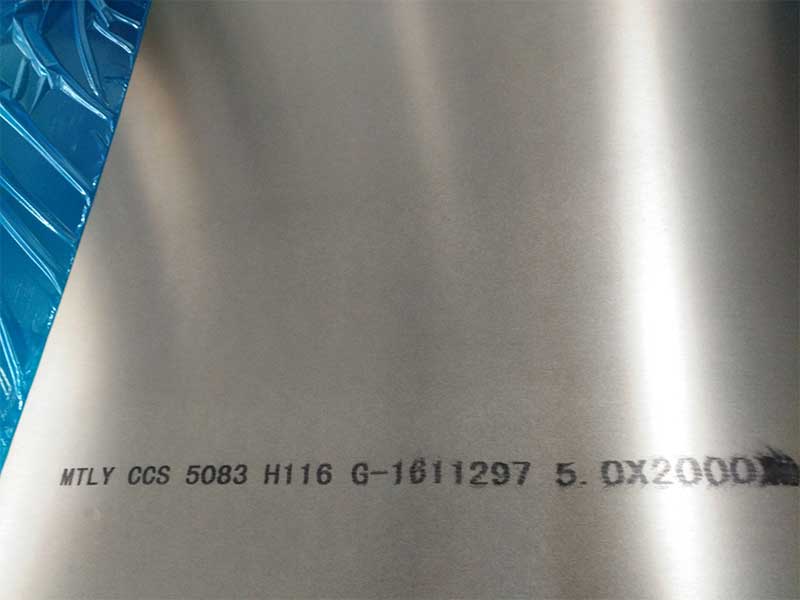

Aluminum sheet 5083 h116 with certificate of CCS for marine

Aluminum Sheet 5083 H116 is a high-strength, corrosion-resistant aluminum magnesium alloy designed specifically for demanding marine applications. Known for its excellent performance under seawater exposure and superior mechanical strength, the 5083 alloy is broadly utilized in shipbuilding, offshore platforms, and other marine structures. With certification from the China Classification Society (CCS), this product offers quality assurance and compliance with international marine standards.

Product Name: Aluminum Sheet 5083 H116Certifying Body: China Classification Society (CCS)Application: Marine, Shipbuilding, Offshore platforms, Oil & Gas rig componentsThickness Range: 2mm to 150mm (standard, can be customized)Width Range: Up to 2500mmLength: Tailored based on order

Chemical Composition (Typical)

| Element | Mg (Magnesium) | Mn (Manganese) | Cr (Chromium) | Fe (Iron) <= | Si (Silicon) <= | Cu (Copper) <= | Zn (Zinc) <= | Al (Aluminum) remainder |

|---|---|---|---|---|---|---|---|---|

| % Weight | 4.0 – 4.9 | 0.4 – 1.0 | 0.05 – 0.25 | 0.4 | 0.4 | 0.1 | 0.25 | Balance |

Note: All values are subject to minor variations depending on supplier and batch.

Mechanical Properties

| Property | Typical Value | Standard/Notes |

|---|---|---|

| Tensile Strength (σb) | 290 – 335 MPa | ASTM B926, EN 485 |

| Yield Strength (σ0.2) | ≥ 145 MPa | |

| Elongation (%) | ≥ 12% | 50mm gauge length |

| Hardness (HB) | 70 – 90 | Brinell Hardness |

| Density | 2.66 g/cm³ |

Temper Designation and Definition: H116

- H116 temper denotes the stabilized condition of the 5083 alloy sheet to be used without strain-ageing, which safeguards the material’s resistance to sensitization in marine environments.

- After rolling and annealing, the material undergoes strain hardening, followed by stabilization heat treatments unique to the temper H116.

- Alleviates the risk of exfoliation corrosion, specifically vital for marine-grade aluminum subjected to saltwater.

Implementation and Quality Standards

- CCS Certification: Aluminum sheet 5083 H116 comes with a Certification by CCS that confirms compliance with marine engineering standards, ensuring material traceability and factory audits.

- Production Standards:

- GB/T 15115-2008 (Aluminium and aluminium alloy sheets)

- ASTM B928/B928M

- ISO 6361:2012

- EN AW-5083 standards as per EN 485-2

- Corrosion Resistance: Designed to withstand harsh saltwater and marine atmospheres, ideal for hulls, decks, and superstructures.

- Welding & Fabrication: Suitable for gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and has excellent cold working and machining capabilities.

Benefits for Marine Applications

- Exceptional Corrosion Resistance: Due to the magnesium-rich chemical make-up, the 5083 alloy is highly resilient against seawater corrosion and exfoliation.

- High Strength with Toughness: The H116 temper preserves excellent mechanical strength while maintaining ductility necessary for shaping and impact-resistance on maritime structures.

- Lightweight: Compared with steel, the lower density means improved fuel efficiency and payload capacity.

- Certified Reliability: CCS certification validates conformity to strict safety and performance metrics critical in the marine industry.

- Versatility: Works well across various marine exterior and interior applications, including bulkheads, decks, pressure vessels, and structural components.

Applications in Marine Environment

- Marine vessel hulls and superstructures

- Offshore drilling platforms and construction

- Energy pipeline supports and cargo tanks

- Shipbuilding structural components requiring exotic corrosion resistance

- High wear surfaces like protective cladding

Related Products

Marine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsRelated Blog

5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View DetailsAluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View Details

Leave a Message