Marine Aluminum Pipe Elbow with Anti Corrosion Coating

Marine Aluminum Pipe Elbow with Anti‑Corrosion Coating: The “Silent Joint” That Decides Your System’s Lifespan

Most engineers look at a marine pipeline and focus on the straight runs: wall thickness, flow rate, pump head. Yet the actual “decision points” of any marine piping system are the elbows. Every bend is a turbulence generator, a stress concentrator, and—if it’s not handled correctly—a corrosion hotspot.

This is where the marine aluminum pipe elbow with anti‑corrosion coating quietly becomes the most strategic component in the line. Not the biggest, not the most visible, but the place where material science, hydrodynamics, and electrochemistry collide.

Why Aluminum Elbows Behave Differently in Marine Environments

Marine aluminum elbows do not simply replace carbon steel bends; they change the system’s behavior.

Steel elbows at bends typically carry:

- A sharp local increase in weight and support load

- High susceptibility to galvanic coupling when connected to other metals

- Significant scaling and rust products that alter internal surface roughness

Marine aluminum elbows, by contrast, introduce:

- Radically lower weight at structural stress points

- Naturally forming passive oxide film that supports coated systems

- More stable and predictable internal surface behavior under seawater, particularly with proper coatings

Under dynamic loads—vessel motion, vibration from pumps, thermal cycling—an elbow’s low mass becomes a critical factor. The lighter the bend, the less inertial load transferred to flanges, supports, and nearby welds. Aluminum excels here, especially in large‑diameter cooling water, ballast, and fire main systems.

The Coating is not an Accessory; It’s an Engineered Layer in a System

Viewing anti‑corrosion coating as “paint” is one of the most expensive misconceptions in marine design.

On a marine aluminum pipe elbow, the coating has three distinct roles:

- Electrochemical shield: reducing exposure to chlorides and dissolved oxygen

- Surface energy manager: controlling adhesion, fouling, and scaling tendencies

- Mechanical buffer: protecting against erosion at high‑velocity impact zones on the intrados and extrados of the bend

The best designs treat base metal and coating as a composite system, not a metal plus a decorative layer. Surface preparation, alloy choice, temper condition, and coating chemistry must be coordinated.

Marine Aluminum Alloys for Pipe Elbows

Marine elbows are typically fabricated from 5xxx and 6xxx series aluminum alloys. Each family addresses a different problem: strength versus formability versus corrosion resistance.

Common alloy choices for marine elbows:

- 5083: High‑strength, excellent seawater resistance, good weldability

- 5086: Better cold formability than 5083, very good corrosion resistance

- 6061: Good balance of strength and machinability, used where complex fittings or machining details are needed

- 6082: High strength among 6xxx, increasingly used in structural piping and offshore applications

The 5xxx series alloys rely on magnesium as the primary alloying element, delivering superior resistance to seawater and stress‑corrosion cracking, especially in the appropriate temper for piping components.

Alloy Tempering: Why the “Soft” States Win at the Bend

A straight pipe might be optimized in a higher‑strength temper, but an elbow is a localized forming zone. Over‑hardened tempers can crack during bending, or end up with work‑hardened zones that behave unpredictably under cyclic loads.

Typical temper selections for marine aluminum elbows:

- 5083‑O or 5083‑H111: Annealed or lightly strain‑hardened, ideal for cold forming into elbows; good toughness and weldability

- 5086‑O / H111: Similar rationale, with slightly better formability

- 6061‑O for forming, then post‑forming heat treatment to 6061‑T6 or T651 for increased strength if the process allows

A critical insight: for elbows in high‑vibration or pressure‑cycling systems, ductility can be more valuable than ultimate tensile strength. A properly formed O‑temper elbow with good wall uniformity and coating will typically outlast a higher‑strength, poorly formed elbow that harbors residual stresses and microcracks.

Implementation Standards: Where Design Discipline Meets Real‑World Loads

Although standards vary by region and classification society, high‑quality marine aluminum pipe elbows are typically designed and produced in line with a cluster of norms instead of a single document.

Relevant frameworks often include:

- ISO and EN standards for wrought aluminum products, such as EN 573 (chemical composition) and EN 485 (mechanical properties and tolerances)

- Pressure piping and fitting references (e.g., EN 10253 style dimensional logic, adapted for aluminum)

- Classification society rules from DNV, ABS, LR or CCS for aluminum piping systems, particularly for fire main, cooling water, bilge, and ballast lines

- Coating standards such as ISO 12944 for corrosion protection of steel structures adapted in practice to aluminum, and IMO PSPC concepts for durability targets

When a manufacturer designs an aluminum elbow claiming “marine grade,” a competent buyer verifies more than just the alloy number. Dimensional tolerances, wall thinning limits at the bend, ovality, and coating thickness control are equally important.

Typical Dimensional and Performance Parameters

While exact values vary by project, typical parameter ranges for marine aluminum pipe elbows include:

- Nominal diameters: commonly DN 25 to DN 600 and above for main seawater lines

- Bend radii: short radius (about 1D) for tight spaces, long radius (about 1.5D or greater) for reduced pressure drop and erosion

- Wall thickness: tailored to pressure class, often following calculations similar to EN or ASME pressure piping concepts but using aluminum’s allowable stresses

- Pressure ratings: low to medium pressure for many seawater service lines, up to higher classes for specialized systems, with attention to fatigue under pulsating loads

- End connections: butt‑weld, flanged, or grooved; weld‑end elbows are common where weight and corrosion resistance are priorities

From a flow perspective, long‑radius elbows in aluminum offer an underrated gain: the combination of a smoother internal surface from extrusion or forming plus properly cured coating can slightly reduce friction factors compared with rougher ferrous bends, which gradually degrade as corrosion products form.

Chemical Composition: The Alloy Behind the Coating

Below is a representative chemical composition table for commonly used marine aluminum alloys for elbows. Actual production heat analysis should always be verified against relevant standards such as EN 573 or AA specifications.

| Alloy | Si (max %) | Fe (max %) | Cu (max %) | Mn (max %) | Mg (%) | Cr (max %) | Zn (max %) | Ti (max %) | Others (each %) | Others (total %) | Al (approx.) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.40 | 0.40 | 0.10 | 0.40–1.0 | 4.0–4.9 | 0.05–0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Balance |

| 5086 | 0.40 | 0.50 | 0.10 | 0.20–0.7 | 3.5–4.5 | 0.05–0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Balance |

| 6061 | 0.40–0.8 | 0.70 | 0.15–0.40 | 0.15 | 0.8–1.2 | 0.04–0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Balance |

| 6082 | 0.70–1.3 | 0.50 | 0.10 | 0.40–1.0 | 0.6–1.2 | 0.25 | 0.20 | 0.10 | 0.05 | 0.15 | Balance |

The magnesium content in 5xxx alloys is the lever for seawater corrosion resistance and strength. Chromium, manganese, and trace elements fine‑tune grain structure and resistance to exfoliation and stress‑corrosion cracking, which is critical in curved, stressed sections such as elbows.

Anti‑Corrosion Coating Systems: More Than Just Epoxy

The elbow is a high‑risk zone for erosion‑corrosion due to:

- Acceleration of flow on the outer radius

- Micro‑cavitation in high‑velocity systems

- Sand or particulate loading in seawater

A proper coating system for marine aluminum elbows typically integrates:

- Chemical conversion or adhesion promotion: chromate‑free conversion coatings or adhesion promoters designed specifically for aluminum, enhancing bonding between substrate and primer

- Primer layer: epoxy or epoxy‑polyamide primer optimized for aluminum’s oxide surface, forming the foundation for barrier performance

- Intermediate and topcoats: high‑build epoxy, epoxy glass‑flake, or polyurethane systems, depending on immersion or splash zone exposure

In immersed seawater service inside the elbow, specialized internal linings such as solvent‑free epoxies or reinforced epoxy systems are often selected for high‑velocity conditions.

A subtle but important point: aluminum naturally forms a stable oxide layer, but this passive film also makes coating adhesion highly technique‑sensitive. Poor surface preparation can lead to underfilm corrosion and blistering, especially around welds and heat‑affected zones (HAZ) near the elbow ends.

Mechanical Behavior: How the Elbow Responds Under Real Loads

The elbow in an aluminum marine pipeline is a multi‑axis stress point. It experiences:

- Internal pressure and pressure fluctuations

- Bending from misalignment and hull or structure deformation

- Vibration from rotating machinery

- Thermal expansion and contraction

Aluminum’s lower modulus of elasticity compared to steel means the elbow can flex more under load, distributing stress more smoothly if properly supported. This flexibility can be an advantage in marine structures that constantly move, such as high‑speed craft, offshore platforms, and floating structures.

The temper state profoundly affects this behavior:

- O‑temper elbows absorb more deformation without cracking and provide better resistance to low‑cycle fatigue when wall thickness and support spacing are correctly engineered

- Age‑hardened tempers like 6061‑T6 offer high strength but require precise control of bending processes and post‑forming heat treatment to avoid microcracks

When elbows are welded into the system, the weld metal and HAZ may have slightly different mechanical properties from the parent elbow. A well‑matched filler alloy (for example, 5356 for many 5xxx alloys) and refined welding procedures reduce galvanic potential differences and local soft zones.

Galvanic Considerations: The Elbow as an Interface Component

Marine aluminum elbows often connect to dissimilar metals: bronze valves, stainless spools, or even coated steel manifolds. In wet, chloride‑rich environments, this can create galvanic cells that consume the less noble metal.

A high‑quality coated marine aluminum elbow is designed as an electrochemical buffer:

- External coatings minimize direct seawater contact and reduce galvanic coupling area

- Internal liners help isolate aluminum from stainless or copper‑nickel system components

- Design details, such as electrically insulating gaskets, sleeves, or flange isolating kits, are used at dissimilar metal joints

Integrating Parameters, Standards, and Coatings into Real‑World Marine Use

When specifying or designing a marine aluminum pipe elbow with anti‑corrosion coating, the most reliable long‑term performance comes from synchronizing:

- Alloy and temper with forming method, required strength, and expected vibration

- Dimensional standards with classification society rules and site‑specific pressure and flow conditions

- Coating system with both the external environment (immersed, splash, atmospheric) and internal service (velocity, temperature, abrasives)

- Welding, NDT, and inspection standards with coating preparation, so that quality control supports both structural integrity and surface performance

Instead of treating these elbows as commodity fittings, treating them as “engineered nodes” in a dynamically loaded, chemically aggressive circuit transforms reliability.

When to Prefer Marine Aluminum Coated Elbows Over Conventional Alternatives

Patterns emerge across real installations:

- High‑speed vessels and lightweight craft gain substantial structural advantages from weight reduction at elbows, improving stability and fuel consumption

- Offshore platforms and floating units benefit from lower dynamic loads on supports and racks, reducing fatigue damage where the pipework attaches to structure

- Ferries, workboats, and patrol vessels using aluminum superstructures gain corrosion consistency and simpler material management by standardizing on marine aluminum fittings coated for duty

Particularly in seawater cooling, ballast, bilge, and fire main systems, the combination of a marine aluminum elbow and a correctly specified anti‑corrosion coating transitions the elbow from being a known “problem point” to a predictable, inspectable, and long‑lived component.

A piping system reveals its true quality not in the straight runs, but where it bends, joints, and interfaces. The marine aluminum pipe elbow with anti‑corrosion coating is the quiet test of design depth:

- If the alloy, temper, geometry, coating, and standards converge intelligently, the elbow disappears from your maintenance log.

- If any of these elements are misaligned, the elbow becomes the first leak, the first pitting site, the first vibration crack.

Seeing marine aluminum elbows as “silent joints” that arbitrate between mechanical load, fluid dynamics, and electrochemistry leads to better engineering choices—and healthier ships, platforms, and coastal infrastructure over the long term.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

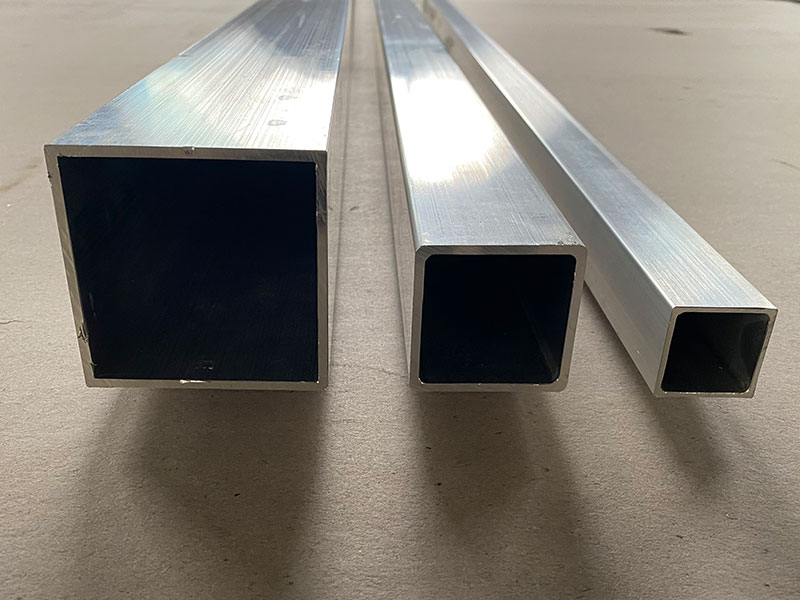

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

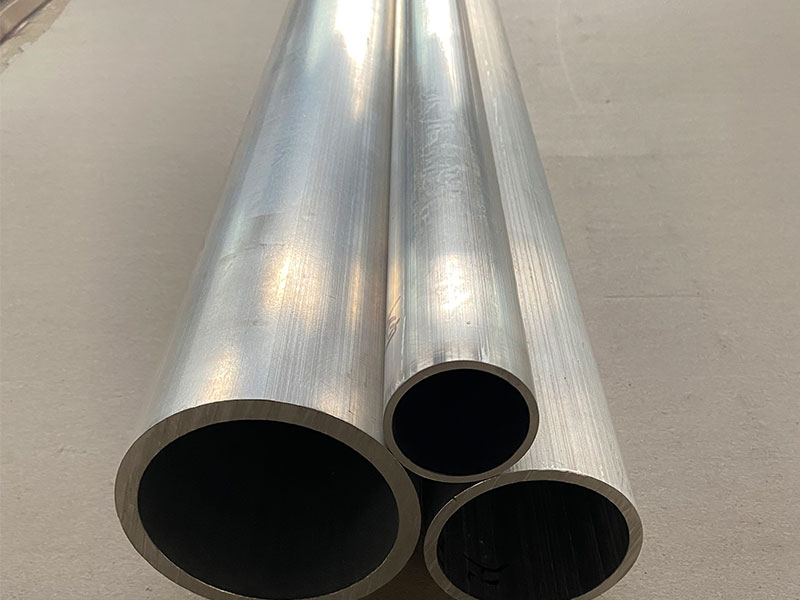

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

Corrosion Resistant Aluminum Pipe Elbow for Offshore Platforms

In the challenging conditions of offshore platforms, where exposure to harsh saline water, high pressure, and fluctuating temperatures is constant, choosing the right piping components can make or break operational efficiency.

View Details6082 Marine Aluminum Tubes for Coastal Marine Infrastructure

In native natural ecosystems straddling our planet’s coastlines, coastal marine infrastructure serves as the lifeblood of myriad industries, ranging from transportation to tourism, aquaculture, and conservation initiatives.

View Details5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View DetailsMarine Aluminum Pipe Elbow for Marine HVAC Systems

In the marine industry, HVAC (Heating, Ventilation, and Air Conditioning) systems play a pivotal role in maintaining a comfortable and functional environment on ships and offshore platforms.

View DetailsCustom Made Marine Aluminum Elbow for Offshore Installations

Custom made marine aluminum elbows are corrosion‑resistant, lightweight, and high‑strength fittings engineered for offshore installations, topside piping, and subsea support systems.

View DetailsMarine Aluminum Elbow for Fuel System Installations

When it comes to designing and installing fuel systems in marine environments, using the right materials is paramount. Among these materials, Marine Aluminum Elbows is know due to their remarkable properties and advantages.

View Details

Leave a Message