Marine Anodized Aluminum Sheets are high-quality aluminum alloy products that combine the inherent lightweight strength and corrosion resistance of marine-grade aluminum with the enhanced durability and aesthetic appeal of anodized surface treatment. Specifically engineered for use in harsh marine environments, these sheets are widely used in shipbuilding, offshore structures, coastal architecture, and marine equipment where resistance to corrosion, wear, and UV degradation is critical.

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061). These aluminum substrates undergo an electrochemical anodizing process that forms a controlled, stable oxide layer on the surface. This anodic oxide film is:

Integral to the aluminum surface (not a coating or paint)

Hard, durable, and resistant to abrasion

Highly corrosion-resistant, especially in saltwater environments

Able to accept a variety of color dyes for decorative finishes

The result is a sheet product that offers extended service life, reduced maintenance, and an attractive, uniform finish ideal for marine applications.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Base | Typically 5xxx (like 5083, 5052) or 6xxx (6061) alloys known for excellent corrosion resistance and strength | Long-term durability in saltwater and coastal environments |

| Anodized Surface Layer | Electrochemically-grown aluminum oxide layer, typically 10-25 microns thick | Enhanced wear resistance, corrosion protection, and UV stability |

| Color and Finish Options | Clear anodized or colored finishes (bronze, gold, black, etc.) possible through dyeing | Aesthetic versatility for marine and architectural projects |

| Environmental Resistance | Excellent withstand against marine weathering, oxidation, salt spray, and sunlight | Minimal maintenance and corrosion prevention |

| Non-Peeling and Non-Flaking | Unlike paint or powder coating, anodized layers are an integral part of the metal surface | Long-lasting, maintenance-free finish |

| Lightweight and Strong | Maintains aluminum’s low density (~2.7 g/cm³) with high strength-to-weight ratio | Easy handling and structural compliance |

| Sustainable & Recyclable | Aluminum is fully recyclable, and anodizing is an environmentally friendly process with no heavy metals or VOCs | Environmentally responsible material choice |

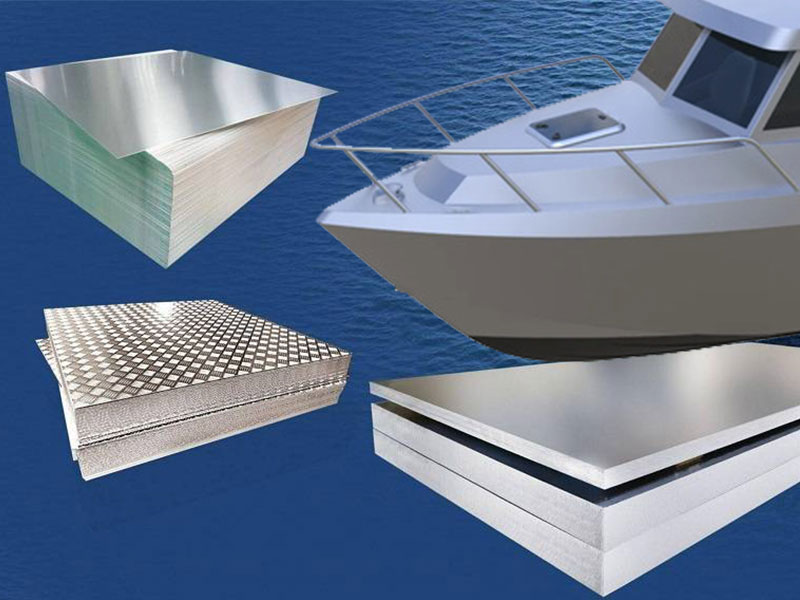

Typical Applications

Ship and yacht superstructures, hull components, and trim

Offshore platform panels and architectural elements

Coastal building facades and window frames

Marine signage, railings, and ladders

Equipment housings, cabinets, and instrument panels

Ventilation covers and decorative marine hardware

Aluminum Alloys and Chemical Composition

Marine anodized aluminum sheets predominantly use alloys that exhibit excellent corrosion resistance in marine environments. Below are two commonly used alloys with their typical chemical compositions:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | Remainder |

Mechanical Properties

| Property | 5083-H111 | 6061-T6 |

|---|---|---|

| Tensile Strength (MPa) | 275 - 345 | 310 - 350 |

| Yield Strength (MPa) | 145 - 215 | 270 - 300 |

| Elongation (%) | 12 - 20 | 8 - 12 |

| Hardness (Brinell) | 75 - 95 | 95 - 115 |

| Density (g/cm³) | 2.66 | 2.70 |

The anodizing process does not significantly affect mechanical properties since it forms a surface oxide layer without altering the bulk metal structure.

The Anodizing Process

Anodizing is an electrochemical process where the aluminum sheets act as an anode in an electrolytic solution, typically sulfuric acid. The process involves:

Surface Preparation: Cleaning and degreasing to remove contaminants.

Electrolytic Oxide Formation: Applying electrical current to form a thick oxide layer (typically 10 – 25 microns).

Coloring (Optional): Dyeing the porous oxide layer before sealing can produce various colors.

Sealing: Hydrating the oxide to close pores and enhance corrosion resistance.

Surface Finishes and Colors

| Finish Type | Description | Typical Thickness | Application |

|---|---|---|---|

| Clear Anodized | Natural silver metallic appearance | 10-25 microns | Standard marine corrosion protection |

| Colored Anodized | Bronze, black, blue, gold, custom colors | 12-20 microns | Architectural appeal, branding, aesthetics |

| Matte/Satin Finish | Slightly textured surface appearance | Varies | Reduced glare and decorative uses |

| Bright/Durable Finish | Polished or buffed before anodizing | Varies | High-end yacht trim and fixtures |

Corrosion Resistance and Maintenance

Anodized aluminum sheets are ideal for marine environments due to the tightly bonded oxide layer acting as a robust corrosion barrier. The anodic film protects aluminum from saltwater attack, pitting corrosion, and general atmospheric degradation.

Maintenance Tips:

Clean regularly with fresh water and mild detergent to remove salt deposits.

Avoid harsh chemicals and abrasive materials to preserve the anodized finish.

Inspect periodically for any physical damage or surface wear; anodizing can be reapplied if necessary.

Advantages Over Other Coatings

| Property | Anodized Aluminum | Painted Aluminum | Powder-Coated Aluminum |

|---|---|---|---|

| Corrosion Resistance | Excellent, integral oxide layer | Good initially but may chip or peel | Good, but may suffer UV degradation |

| Wear Resistance | High (hard oxide surface) | Moderate | High, but can scratch |

| Maintenance | Low, long-lasting finish | Requires periodic repainting | Requires maintenance |

| Environmental Impact | Environmentally friendly process | Involves VOCs and chemicals | Contains solvents; less eco-friendly |

Ordering Information

When ordering Marine Anodized Aluminum Sheets, please specify:

Aluminum alloy (e.g., 5083-H111, 6061-T6)

Sheet dimensions and thickness (typically 1mm to 6mm or thicker)

Desired anodized finish (clear or colored) and thickness of anodizing layer

Surface texture or finish preferences (matte, satin, bright)

Any fabrication requirements such as cutting, forming, or drilling

We offer custom anodizing and fabrication services to satisfy marine-grade standards.

Marine Anodized Aluminum Sheets are an exceptional choice for marine and offshore applications requiring the perfect balance of corrosion resistance, mechanical strength, and aesthetic appeal. The anodizing process enhances aluminum’s natural advantages by providing a hard, stable, and durable surface that withstands the challenges of the marine environment with minimal maintenance. By selecting the appropriate alloy, anodizing thickness, and finish, customers gain a long-lasting solution ideally suited for both structural and decorative marine projects.

For expert consultation, technical advice, and custom orders, please contact our knowledgeable sales and engineering team.