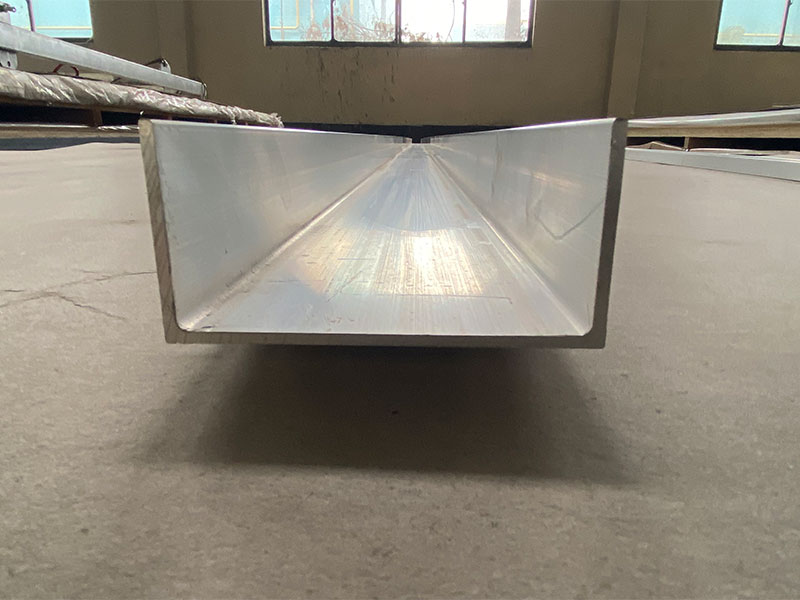

5083 Marine Aluminum Z Shaped Sections for Offshore Vessel Frame Design

In the demanding offshore marine environment, the structural integrity and corrosion resistance of vessels are crucial for reliable performance and safety. The use of 5083 Marine Aluminum Z Shaped Sections provides an optimized solution tailored specifically for offshore vessel frame designs.

5083 alloy is a magnesium-manganese based aluminum plate well-known for excellent corrosion resistance, particularly in seawater and marine atmospheres. It is non-heat-treatable but gains strength from cold working processes. Commonly employed in shipbuilding, transportation, and Arctic structure applications, 5083 alloy also provides exceptional weldability and good fatigue strength.

Z Shaped Sections: An Integral Profile for Structural Framing

Z shaped sections are structural profiles formed in a “Z” contour with precise dimensions tailored per design requirements. Their shape facilitates effective load distribution, makes them easy to connect with flat plates or other sections, and improves overall structural rigidity.

- Lightweight compared to steel, helping with flotation and fuel efficiency

- Boltable and weldable sections simplify offshore assembly and maintenance

- Precision-manufactured with tight dimensional tolerances

- Engineered stiffness due to profile geometry

- Facilitate cable or pipe supports along vessel frames

Chemical Composition of 5083 Alloy (Typical, wt%)

| Element | Mg | Mn | Cr | Fe | Si | Zn | Cu | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| % Wt | 4.0-4.9 | 0.4-1.0 | 0.05-0.25 | 0.4 max | 0.4 max | 0.25 max | 0.1 max | 0.15 max | Remainder |

Mechanical Properties for 5083 Alloy (Typical values)

| Property | Unit | Value |

|---|---|---|

| Tensile Strength (Ultimate) | MPa | 275 - 310 |

| Yield Strength (0.2% offset) | MPa | 145 - 190 |

| Elongation at Break | % | 12 – 22 |

| Hardness (Brinell) | BHN | 68 - 92 |

| Density | g/cm³ | 2.66 |

| Modulus of Elasticity | GPa | ~70 |

Features of 5083 Marine Aluminum Z Shaped Sections

1. Superior Corrosion Resistance

5083’s high magnesium and chromium content ensure excellent performance in aggressive marine environments. These Z sections resist pitting and stress corrosion cracking from saltwater exposure, significantly improving vessel longevity.

2. High Strength-to-Weight Ratio

Aluminum 5083 maintains high structural strength alongside substantial weight savings vs. steel. This allows offshore vessels to be lighter, enhancing fuel efficiency and handling without sacrificing integrity.

3. Outstanding Weldability

These sections respond well to all common welding techniques including GTAW (TIG), GMAW (MIG), and friction stir welding, critical for modular offshore assembly or in-field repairs.

4. Excellent Fabricability

5083 Z sections can be cut, formed, and machined with ease, giving flexibility for complex offshore hull and frame designs.

5. Heat Treatment Stability

Being non-heat-treatable, their performance remains stable after welding or thermal exposure as long as correct fabrication processes are followed.

6. Resistance to Fatigue and Impact

Offshore vessels encounter cyclic loads and impacts; 5083 alloy exhibits proven fatigue performance minimizing crack initiation and growth in supporting frames.

Application in Offshore Vessel Frame Design

5083 marine aluminum Z shaped sections excel in multiple vessel framing applications due to their light weight, corrosion resistance, and design flexibility:

- Frame Members & Structural Supports: Excel in longitudinal and transverse framing offering optimal load transfer with minimum weight.

- Bulkheads & Longitudinal Stringers: Serve as components to define large compartment shapes and withstand hydrostatic pressure variations.

- Deck Beams and Ribs: Provide durable stiffening while reducing deck weight.

- Superstructure Concaves and Offshore Platforms: Useful for deckhouse framing due to corrosion resistance in overhead marine environments.

- Pipe and Cable Support Systems: Their standardized shapes support pipe runs and cable trays, integrating efficiently into existing frames.

Benefits in Offshore Design

- Increased Service Life: Combatting harsh marine conditions reduces need for replacement or frequent repair.

- Lower Lifecycle Costs: Material choice decreases corrosion-related maintenance and downtime.

- Improved Operational Safety: Constructs frame designs with superior structural integrity to resist extreme loads.

- Environmentally Friendly: Aluminum’s recyclability contributes to sustainable shipbuilding practices.

Customization and Fabrication Options

Yours truly’s production line includes capability for customized melting, extrusion, and surface finishing to meet varied project demands:

- Varied surface treatments such as anodizing, powder coating, or anti-fouling coatings to tailor corrosion resistance.

- Military-grade or commercial certifications available upon request (e.g., ISO, ABS, DNV class rules).

- Custom section dimensions can be produced based on project engineering drawings.

- Available lengths up to 6 meters or cut-to-length options for onsite installation ease.

Related Products

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 Marine Aluminum Z Shaped Sections for Offshore Vessel Frame Design

In the demanding offshore marine environment, the structural integrity and corrosion resistance of vessels are crucial for reliable performance and safety.

View Details5083 Marine Aluminum Round Bar for Durable Offshore Vessel Parts

When it comes to constructing durable offshore vessel parts, material choice is paramount. Among various options, 5083 marine aluminum round bar stands out as a highly reliable and versatile solution.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View Details5083 Marine Aluminum Channels for Offshore Platform Construction

In the demanding world of offshore platform construction, material selection forms the backbone of structural integrity, durability, and performance. With increasing emphasis on lightweight and corrosion-resistant materials.

View Details

Leave a Message