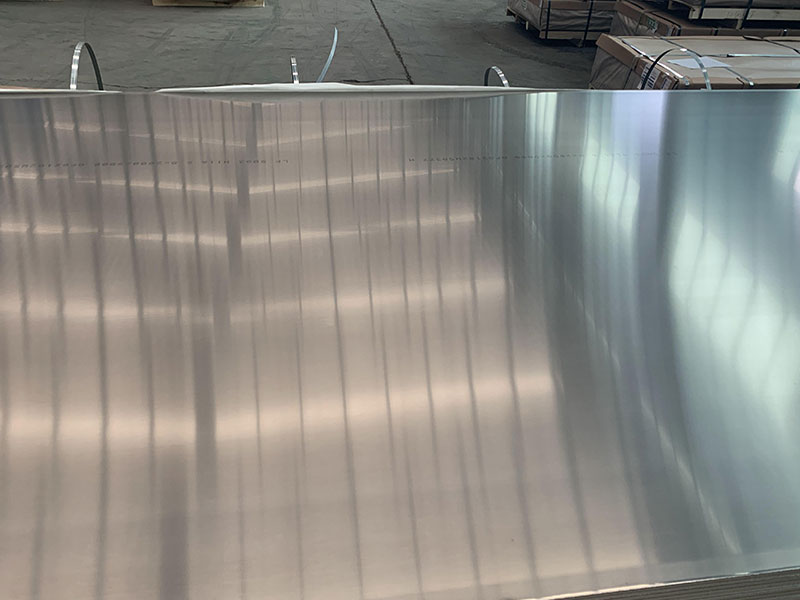

Marine aluminium alloy sheet

Marine aluminum alloy sheet is an indispensable material in the construction and maintenance of vessels, offshore platforms, and various marine infrastructure. Its unique combination of strength, corrosion resistance, and lightweight properties makes it a superior choice compared to traditional materials such as steel or untreated aluminum.

Marine Aluminum Alloy Sheet

Marine aluminum alloy sheets are specially engineered aluminum alloys formulated to withstand harsh marine environments. These sheets combine excellent mechanical properties with superior corrosion resistance, especially against saltwater. The alloys typically fall within the 5xxx and 6xxx series aluminum grades due to their beneficial attributes of strength, weldability, and resistance to stress corrosion.

Functions and Advantages

Corrosion Resistance:The saltwater environment is highly aggressive to metals. Marine aluminum alloy sheets, particularly those in the 5xxx series (e.g., 5083, 5052) contain magnesium as their primary alloying element, which drastically improves corrosion resistance, especially against seawater-induced pitting and crevice corrosion.

Lightweight and High Strength:With up to 60% weight reduction compared to steel, marine aluminum enables enhanced fuel efficiency and ease of handling without compromising structural integrity. This is critical in vessel performance and operational cost reduction.

Excellent Weldability and Fabrication:These sheets can be hot or cold worked and welded with minimal strength loss, allowing flexibility in manufacturing diverse ship and offshore structures while maintaining their engineered toughness.

Superior Fabrication Tolerances:The sheets offer good surface finish, dimensional stability, and are easier to paint and coat, which are important for long-term maintenance.

Typical Technical Parameters and Alloy Temper Codes

| Property | Unit | Alloy 5083-H116 | Alloy 5052-H32 | Alloy 6061-T6 |

|---|---|---|---|---|

| Density | g/cm³ | 2.66 | 2.68 | 2.70 |

| Tensile Strength | MPa | 300 – 350 | 220 – 290 | 275 – 310 |

| Yield Strength | MPa | 215 – 250 | 110 – 170 | 240 – 270 |

| Elongation (%) | % | 12 – 18 | 10 – 15 | 10 – 17 |

| Corrosion Resistance | Excellent | Excellent | Good | Moderate |

Temper Code:

- H116: Non-heat treatable alloy protected primarily by its temper and chemical composition, with enhanced corrosion resistance post welding.

- H32: Strain hardened and partially annealed for a medium degree of strength and improved ductility.

- T6: Solution heat-treated and artificially aged for high strength and good machinability.

Implementation Standards

Marine aluminum alloy sheets must comply with stringent industrial and maritime standards to guarantee consistent performance in harsh environments. standards include:

ABS (American Bureau of Shipping) Rules: Structural materials must meet ABS specifications, emphasizing fatigue, strength, and corrosion resistance. Alloy 5083-H116 is often specified in shipyard fabrication.

ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate, detailing chemical ranges, mechanical properties, and heat treatment qualifications.

ISO 6361: Specifies requirements for wrought aluminum alloy sheets designed for marine applications.

Adherence to these standards ensures uniform properties, traceability, and certification suited for international marine projects.

Chemical Composition Detail

| Element | 5083 (wt%) | 5052 (wt%) | 6061 (wt%) |

|---|---|---|---|

| Aluminum | Balance | Balance | Balance |

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 |

| Manganese (Mn) | 0.4 – 1.0 | 0.1 – 0.4 | 0.15 – 0.4 |

| Silicon (Si) | ≤0.4 | ≤0.25 | 0.4 – 0.8 |

| Iron (Fe) | ≤0.4 | ≤0.4 | ≤0.7 |

| Copper (Cu) | ≤0.1 | ≤0.1 | 0.15 – 0.4 |

| Chromium (Cr) | 0.05 – 0.25 | ≤0.05 | 0.04 – 0.35 |

| Zinc (Zn) | ≤0.25 | ≤0.1 | ≤0.25 |

Alloy Tempering and Service Conditions

Marine grades are generally strain-hardened or solution-treated products:

Strain hardened (H temper): Most marine aluminum is not heat-treatable, relying on cold working (e.g., 5052-H32). This enhances strength while maintaining corrosion properties.

Solution treated and artificially aged (T temper): For alloys like 6061, T6 temper boosts tensile strength for structural parts but is less corrosion-resistant in marine saltwater exposure unless protected by coatings or anodizing.

Environmental Considerations: This aluminum performs best maintained in cyclic wet/dry marine atmospheres and salty environments, especially if regular cleaning/desalination is integrated. Protective surface treatments such as anodizing, sealing, and composites add an extra layer of enhancement against corrosive effects.

Applications in Marine Engineering

- Shipbuilding: Hull plating, superstructures, deck panels

- Offshore Platforms: Structural supports, walkways, cladding for corrosion resistance

- Recreational Boats: Lightweight advantage for speed and maneuverability

- Marine Transport Containers: Lightweight yet strong panels resist saline corrosion

- Aquaculture and Maritime Structures: Pens, cages and lightweight construction for floating elements

Related Products

Marine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsRelated Blog

Mill Finish Aluminium Sheet for Ship building

When it comes to shipbuilding, choosing the right materials is pivotal for ensuring both durability and optimal performance. Among various options, mill finish aluminium sheet stands out as a superior choice.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

View DetailsMarine Grade Alloy 5754 Aluminum Sheet

The Marine Grade Alloy 5754 Aluminum Sheet is a premium quality lightweight material specifically engineered to meet the requirements of the marine environment. Our 5754 aluminum sheet boasts exceptional corrosion resistance, high strength.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

View DetailsAluminium sheet 8mm alloy 5052 h112 for boat

When selecting materials for marine applications, especially in boat building, the balance between strength, corrosion resistance, and workability is crucial. Aluminium sheet 8mm thick made from alloy 5052 in temper H112 epitomizes this balance.

View Details

Leave a Message