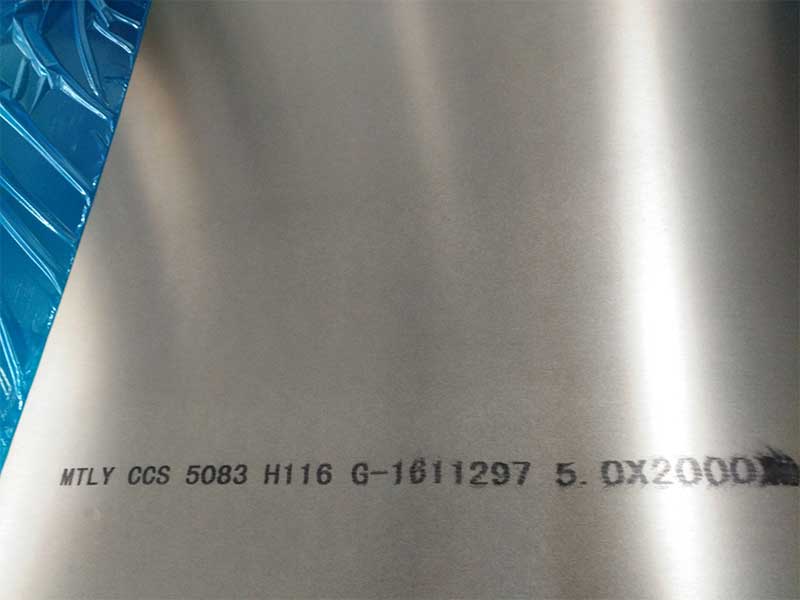

Mill Finish Aluminium Sheet for Ship building

When it comes to shipbuilding, choosing the right materials is pivotal for ensuring both durability and optimal performance. Among various options, mill finish aluminium sheet stands out as a superior choice.

What is Mill Finish Aluminium Sheet?

Mill finish aluminium sheet refers to aluminium in its rawest form right off the production line—it hasn’t been coated, polished, or surface treated beyond what processing inherently produces. The surface is characterized by its natural grey metallic appearance, with visible lines and marks indicating its manufacturing origins. Despite this untreated look, the inherent quality and composition of these mill finish sheets ensure they cater ideally to marine applications, especially shipbuilding.

Why Mill Finish Aluminium for Shipbuilding?

In shipbuilding, material selection criteria extend beyond weight and cost—they include corrosion resistance, strength-to-weight ratio, weldability, and fatigue performance. Aluminium offers significant advantages over steel and composites in many of these aspects, especially when using mill finish aluminium sheets:

- Corrosion Resistance: Marine environments expose vessels to saltwater, which accelerates rust and corrosion on metals like steel. Aluminium naturally forms a protective oxide layer, providing superior corrosion resistance without additional coatings.

- Weight Efficiency: Aluminium’s low density reduces overall vessel weight, increasing fuel efficiency and maneuverability.

- Weldability and Fabrication Ease: Mill finish aluminium sheets facilitate efficient welding and forming, crucial in the complex geometries of ship hulls.

- Strength and Durability: Particular aluminium alloys exhibit excellent tensile strength and toughness necessary for maritime stresses.

the Alloys and Tempering for Marine Use

The choice of aluminium alloy and tempering condition significantly impacts performance in shipbuilding. Common marine-grade aluminium alloys include the 5xxx series, often 5083 and 5005, and the 6xxx series, notably 6061 or 6082. These alloys are favored for:

- Alloy 5083: Known for outstanding corrosion resistance, especially in seawater and marine environments. Also offers excellent strength and formability.

- Alloy 6005A & 6061 (6xxx series): Used when a blend of strength, corrosion resistance, and machinability is required.

Mill finish sheets typically come in various tempers — indicated as H for hardened, O for annealed, or T for heat-treated variants.

| Alloy | Chemical Composition (%) | Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|---|

| 5083 | Mg 4.0-4.9, Mn ≤0.4, Cr 0.05-0.25, Fe ≤0.4, Si ≤0.4 | H111/H116 | 215-300 | 290-350 |

| 5005 | Mg 0.5-1.1, Fe ≤0.7, Si ≤0.3 | H14 | ~110-160 | ~190-230 |

| 6061 | Mg 0.8-1.2, Si 0.4-0.8, Fe ≤0.7, Cu 0.15-0.4 | T6 | 240 | 290 |

Note: Values vary slightly depending on material thickness and processing.

Compliance with Shipbuilding Standards

Mill finish aluminium sheets used in marine applications adhere to stringent international standards to ensure safety, consistency, and reliability.

- IMO (International Maritime Organization): Provides guidelines related to materials’ fire performance and corrosion control.

- ASTM B928: Standard specification for aluminium alloy sheets used in ship hull construction, focusing on composition and mechanical properties.

- ISO 6361 and ISO 8090: These ISO standards specify the requirements for aluminium alloy sheets, including corrosion resistance and acceptable surface conditions — essentials for raw mill finishes prior to any coating.

Adherence to these standards ensures alloys withstand dynamic maritime conditions, from waves pounding the hull to long-term exposure to aggressive saline atmospheres.

Implementation Recommendations in Shipbuilding Projects

- Pre-use Testing: Mill finish aluminium sheets should undergo ultrasonic thickness measurement and non-destructive testing (NDT) to ensure uniform quality.

- Welding Considerations: Utilizing appropriate welding procedures suitable for the chosen alloy and temper is necessary to retain strength.

- Surface Preparation: Though mill finish indicates an untreated surface, additional cleaning or light grit blasting might be required before applying any anti-corrosive coatings when needed.

- Thermal Treatment Verification: Some projects necessitate specific hardening or annealing temper states enhancing stress resistance.

Related Products

Marine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsRelated Blog

0.3mm 0.4mm 0.5mm 1.6mm Thickness Roll Aluminium Coil Sheet 5052 h32 For Boat

When it comes to marine applications, selecting the right material is crucial for performance, durability, and safety. Enter the 5052 H32 marine aluminum coil sheet, available in thicknesses ranging from 0.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsMarin grade aluminum sheet 5052 5mm thick for boat

What is Marine Grade Aluminum 5052?Aluminum 5052 is a non-heat-treatable aluminum-magnesium alloy primarily known for excellent corrosion resistance, high strength among the non-heat treatable grades, and superb weldability.

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details

Leave a Message