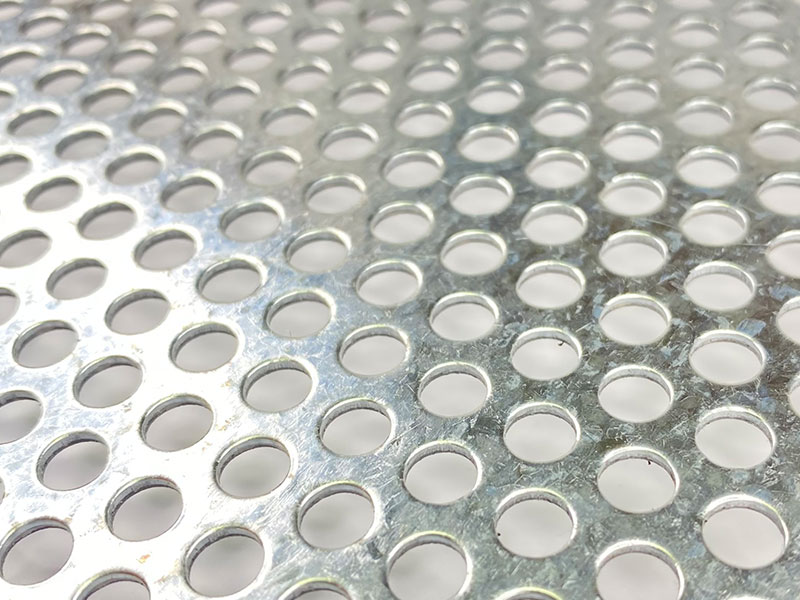

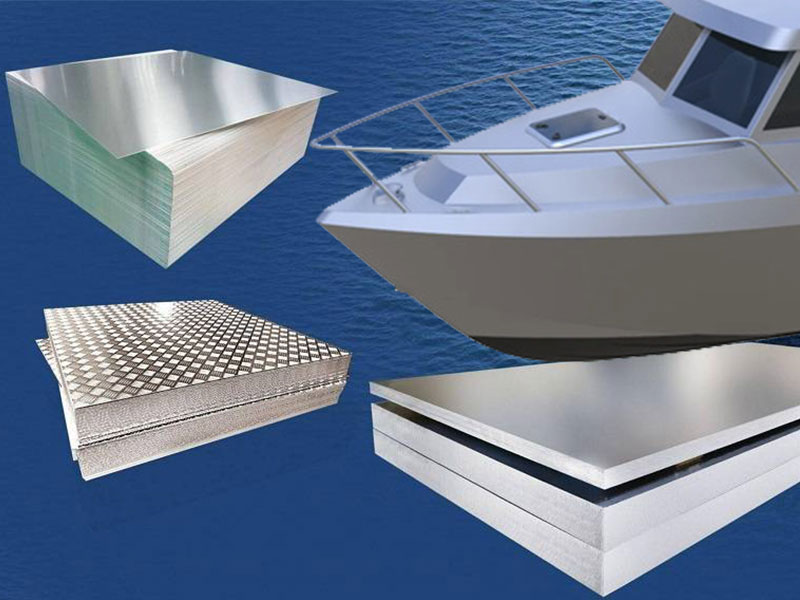

Marine Perforated Aluminum Sheets are engineered aluminum plates specially designed to meet the demanding requirements of maritime and offshore environments. These sheets combine the corrosion resistance and lightweight characteristics of marine-grade aluminum alloys with precision perforations that provide functional advantages such as ventilation, drainage, filtration, and aesthetic appeal. Widely used in shipbuilding, offshore platforms, docks, and marine equipment, these perforated sheets offer excellent durability, versatility, and performance in harsh saltwater conditions.

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications. By utilizing aluminum alloys like 5083 and 6061, these sheets not only maintain incredible corrosion resistance but also keep installation weights manageable—key factors in the marine industry.

Key Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloys | Alloy series 5xxx (e.g. 5083) and 6xxx (e.g. 6061) with superior corrosion resistance | Resists saltwater corrosion and marine oxidation |

| Customizable Perforation Patterns | Round, square, slotted or decorative holes in various diameters and pitches | Enhanced ventilation, drainage, filtration, and visual appeal |

| High Strength-to-Weight Ratio | Lightweight aluminum substrate with structural integrity | Facilitates ease of handling and reduces vessel weight |

| Excellent Fabrication Properties | Easily cut, bent, welded, or formed without degradation | Allows flexibility in marine design and installation |

| Superior Corrosion Resistance | Naturally forms a protective oxide layer; compatible with additional surface treatments | Long-lasting performance in harsh environments |

| Enhanced Drainage and Ventilation | Perforations provide airflow and liquid passage | Prevents water pooling and supports equipment cooling |

| Low Maintenance | Requires minimal upkeep compared to steel alternatives | Reduces operational costs over lifecycle |

Typical Applications

Ship ventilation grilles and air intake covers

Drainage panels and flooring on decks and walkways

Protective guards for marine equipment and engine rooms

Offshore oil platform screens and filtration panels

Decorative facades and architectural marine elements

Sound attenuation panels and enclosures

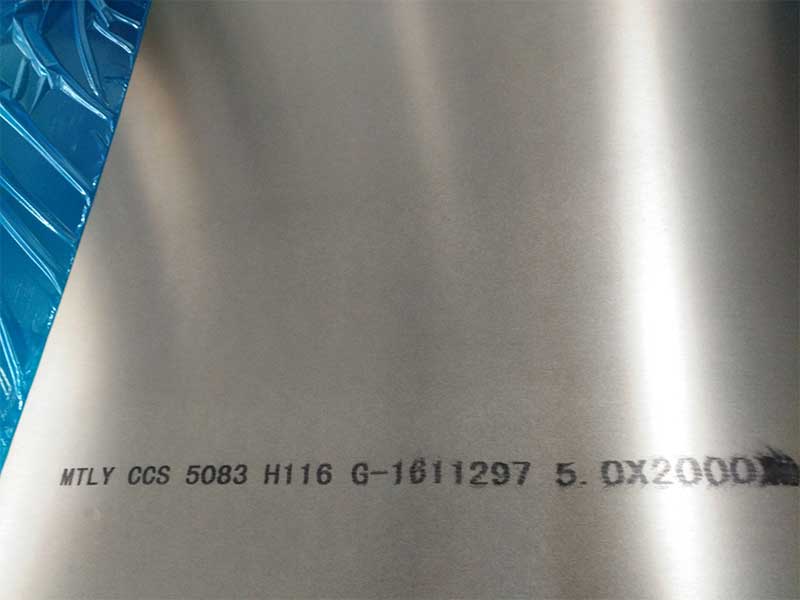

Materials and Chemical Composition

The most commonly used alloys for marine perforated aluminum sheets are 5083 and 6061 due to their balance of strength, corrosion resistance, and fabrication capabilities.

Table 1: Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | Remainder |

Mechanical Properties

Mechanical performance depends on alloy type and temper. Here are typical values for marine-grade perforated aluminum sheets:

Table 2: Mechanical Properties

| Property | 5083-H111 | 6061-T6 |

|---|---|---|

| Tensile Strength (MPa) | 275-345 | 310-350 |

| Yield Strength (MPa) | 145-215 | 270-300 |

| Elongation (%) | 12-20 | 8-12 |

| Hardness (Brinell) | 75-95 | 95-115 |

| Density (g/cm³) | 2.66 | 2.70 |

Perforation Patterns & Specifications

Marine perforated aluminum sheets can be customized to various hole shapes, sizes, and open area ratios depending on application needs:

| Hole Shape | Typical Diameter / Size | Open Area (%) | Applications |

|---|---|---|---|

| Round | 1 mm – 20 mm | 10-50 | Ventilation screens, filtration panels |

| Square | 2 mm – 15 mm | 10-45 | Protective guards, decorative panels |

| Slotted | 3 mm x 10 mm and up | 10-40 | Drainage panels, acoustic panels |

| Decorative | Custom shapes | Variable | Architectural and aesthetic components |

Thickness can range typically from 0.8 mm to 6 mm, with sheet sizes up to 2000 mm width and various lengths.

Corrosion Resistance and Surface Treatment

The marine environment accelerates corrosion, requiring materials with exceptional durability. Aluminum alloys 5083 and 6061 naturally develop a thin oxide layer that protects metal underneath. Additional treatments optimize longevity and appearance:

Anodizing: Improves surface hardness and corrosion resistance with an attractive finish.

Powder Coating or Painting: Adds extra barrier protection and aesthetic options.

Passivation: Chemical treatment to enhance oxide layer formation.

Regular cleaning with freshwater removes salt deposits and prevents surface degradation.

Fabrication and Installation

Marine perforated aluminum sheets are easily fabricated using conventional techniques:

Cutting: Laser, plasma, or water jet cutting for precision.

Forming: Bending, rolling, or stamping as required.

Welding: Compatible with TIG, MIG, and resistance welding for structural installations.

Assembly: Can be bolted or riveted using marine-grade fasteners.

These fabrication options enable seamless integration into ship components, offshore structures, and marine equipment.

Ordering Information

Customers may specify:

Alloy and temper (e.g., 5083-H111, 6061-T6)

Sheet thickness and dimensions

Hole size, shape, pattern, and open area percentage

Surface finish and treatments

Custom fabrication services

We offer tailored solutions to meet your marine project requirements efficiently and reliably.

Marine Perforated Aluminum Sheets provide an exceptional combination of corrosion resistance, strength, and functional perforations suited for a broad spectrum of maritime applications. Their lightweight nature, customizability, and durability make them an outstanding material choice for ventilation, drainage, filtration, protection, and decorative uses in marine environments. Selecting the right alloy and perforation pattern ensures optimized performance and longer operational life in harsh saltwater conditions.

For further information or technical assistance, our expert sales engineers are ready to help you define the ideal marine perforated aluminum solution.