Heavy Duty Aluminum Elbow for Marine Oil and Gas Pipelines

The Heavy Duty Aluminum Elbow for Marine Oil and Gas Pipelines is engineered for long‑term performance in harsh offshore and coastal environments. Designed around corrosion‑resistant aluminum alloys and precision forming, this elbow provides a lightweight, high‑integrity flow path for crude, gas, produced water, and chemical injection lines.

Product Features

- High‑strength marine‑grade aluminum alloy (typical: 5xxx / 6xxx series)

- Excellent resistance to seawater and chloride environments

- Lightweight alternative to carbon steel and duplex stainless steel

- Smooth internal radius for reduced pressure loss and erosion

- Compatible with common offshore connection standards (ANSI / ASME / ISO)

- Suitable for topside, subsea skid, and coastal terminal piping

- Customizable bend radius, wall thickness, and end configurations

Typical Chemical Composition (Alloy Example)

The exact alloy is selected based on project requirements. The table below shows a typical composition for a marine‑grade aluminum alloy (example: 5083‑type for welded elbows). Values are indicative and can be adjusted.

| Element | Symbol | Typical Content (wt%) | Role in Performance |

|---|---|---|---|

| Aluminum | Al | Balance | Base metal providing low density and natural oxide film |

| Magnesium | Mg | 4.0 – 4.9 | Strengthening, improves corrosion resistance in seawater |

| Manganese | Mn | 0.4 – 1.0 | Enhances strength and stress‑corrosion resistance |

| Chromium | Cr | 0.05 – 0.25 | Improves intergranular corrosion resistance |

| Iron | Fe | ≤ 0.40 | Typically limited to reduce inclusions and maintain toughness |

| Silicon | Si | ≤ 0.40 | Controlled to balance castability and mechanical properties |

| Copper | Cu | ≤ 0.10 | Kept very low to avoid pitting in chloride environments |

| Zinc | Zn | ≤ 0.25 | Minor residual, controlled for improved corrosion behavior |

| Others (each) | — | ≤ 0.05 | Trace elements, carefully controlled |

| Others (total) | — | ≤ 0.15 | Overall impurity cap |

Alternative alloys such as 6061‑T6 or 6082‑T6 may be chosen for higher strength or specific fabrication routes, especially for non‑welded elbows.

Technical Specifications

Below is a typical data set for the Heavy Duty Aluminum Elbow family. Project‑specific data sheets are customized to the client’s line class and design code.

General Parameters

| Parameter | Typical Range / Option |

|---|---|

| Nominal pipe size (NPS) | 1" – 24" |

| Standard bend angles | 45°, 90°, 180°; custom angles on request |

| Bend radius (centerline) | 1.5D, 3D, 5D, long‑radius custom |

| Wall thickness schedule | SCH 10 – SCH 80, or custom heavy‑wall |

| Manufacturing process | Hot‑formed, mandrel‑bent, or extruded |

| End connection types | Beveled for welding, flanged, grooved, clamped connector compatible |

| Design codes | ASME B31.3 / B31.4 / B31.8 (project‑dependent), ISO and DNV offshore standards as specified |

| Surface condition | Mill finish, shot‑blasted, anodized, or coated per spec |

| Service media | Crude oil, natural gas, condensate, produced water, seawater, chemicals (per compatibility review) |

Mechanical Properties (At Ambient Temperature)

Representative values for a welded marine‑grade aluminum elbow (example 5083‑O/H112 or similar):

| Property | Typical Value Range | Notes |

|---|---|---|

| Tensile strength, Rm | 270 – 320 MPa | Dependent on temper and thickness |

| 0.2% proof stress, Rp0.2 | 125 – 160 MPa | Typical for welded constructions |

| Elongation (A50) | 10 – 18 % | Good ductility for forming and welding |

| Brinell hardness (HBW) | 65 – 90 | Sufficient for moderate erosion environments |

| Density | ~2.66 – 2.70 g/cm³ | About one‑third the weight of carbon steel |

| Modulus of elasticity, E | ~70 GPa | Lower stiffness vs. steel, considered in design |

| Poisson’s ratio | ~0.33 |

For heat‑treated 6xxx series elbows (e.g., 6061‑T6), tensile and yield strengths are higher, with minor variance in elongation.

Pressure and Temperature Ratings

Aluminum elbows are selected to match the design envelope of the pipeline. Typical capabilities:

| Design Aspect | Typical Capability (Indicative) |

|---|---|

| Design pressure | Up to 40 bar for topside; higher by design check |

| Test pressure | 1.3 – 1.5 × design pressure, hydrostatic |

| Design temperature range | −40 °C to +120 °C (alloy‑ and temper‑dependent) |

| Corrosion allowance | Often minimal due to corrosion resistance; can be specified if required |

| Erosion / velocity limits | Evaluated per service, typically up to 10–15 m/s for clean fluids (project‑specific) |

Pressure ratings are finally governed by design code, wall thickness, bend radius, and weld details.

Corrosion and Surface Protection

Aluminum elbows are particularly suited to marine pipelines because of their inherent corrosion resistance and stable oxide layer.

| Exposure Condition | Performance Description |

|---|---|

| Atmospheric marine | Excellent; low general corrosion rate |

| Immersed in seawater | Very good; Mg‑rich alloys resist pitting |

| Splash and tidal zones | Good; may be combined with coating/anodizing |

| Sour service (H₂S) | Requires specific alloy selection and validation |

| Galvanic coupling | Requires isolation from carbon steel or copper‑based alloys |

Typical surface options:

| Finish / Coating | Purpose |

|---|---|

| Natural oxide (as‑fabricated) | General corrosion resistance in mild conditions |

| Anodizing | Improved hardness, appearance, and resistance |

| Epoxy or polyurethane coating | Extra barrier in heavy fouling or sour environments |

| Insulation + cladding | For thermal control and mechanical protection |

Dimensional and Tolerance Data

To interface reliably with marine pipeline systems, elbows follow strict dimensional control:

| Parameter | Typical Tolerance |

|---|---|

| Bend angle | ±0.5° to ±1.0° depending on size |

| Center‑to‑end length | ±1.0 mm up to DN 100; tighter on request |

| Wall thickness | As per EN / ASTM tolerance classes |

| Ovality of bend | Typically ≤ 5 % |

| Misalignment at ends | ≤ 1.5 mm or project‑specified |

Dimensional checks may include 3D scanning or template gauging for critical subsea spools.

Welding and Fabrication

The elbow is designed for efficient on‑site and workshop integration:

| Aspect | Description |

|---|---|

| Weldability | Good; compatible with common Al filler wires (e.g., 5183, 5356) |

| Recommended processes | GTAW (TIG), GMAW (MIG), mechanized or orbital where applicable |

| Preheat requirements | Generally low or none; controlled heat input recommended |

| Post‑weld heat treatment | Usually not required for 5xxx series; 6xxx series may require specific procedures |

| Non‑destructive testing | Radiography, UT, dye penetrant as specified in project quality plan |

Advantages in Marine Oil and Gas Service

| Advantage Category | Benefit to the Operator |

|---|---|

| Weight reduction | Up to ~65–70 % lighter than carbon steel; enables lighter supports and easier installation |

| Corrosion resistance | Lower risk of external corrosion in salt‑laden atmospheres; reduced coating maintenance |

| Handling and logistics | Easier lifting, fewer heavy‑lift operations, lower vessel crane time offshore |

| Flow assurance | Smooth internal radius, low roughness, reduced pressure drop and turbulence |

| Lifecycle cost | Lower maintenance on topside structures, supports, and interface components |

| Safety | Easier manual handling, fewer heavy loads, lower risk during installation and replacement |

Typical Applications

Heavy duty aluminum elbows are deployed wherever weight, corrosion resistance, and fast installation are critical.

Marine and Offshore Pipelines

| Application Area | Typical Use Cases |

|---|---|

| FPSO and fixed platforms | Topside process lines, flare headers, utility headers |

| Offshore production modules | Oil, gas, condensate, produced‑water and seawater piping |

| Riser and J‑tube interfaces | Alignment elbows, transition spools |

| Deck drains and overboard | Seawater discharge and deluge systems |

Coastal and Terminal Infrastructure

| Facility Type | Sample Services |

|---|---|

| LNG and gas terminals | Utility gas lines, low‑pressure liquid lines |

| Refined product depots | Petrol, diesel, kerosene, and chemical loading lines |

| Desalination / water plants | High‑salinity brine pipelines, seawater intake/outfall |

Subsea and Near‑Shore Systems

| System | Role of Aluminum Elbow |

|---|---|

| Subsea manifolds & skids | Lightweight piping sections and jumper spools |

| Shore approaches | Buried or protected pipelines in tidal zones |

| Floating hose interfaces | Transition pieces where low weight is advantageous |

Customization Options

The elbow family is highly configurable to match project P&IDs, line classes, and layout constraints.

| Customizable Parameter | Options |

|---|---|

| Angle and radius | Non‑standard bends, multi‑plane bends |

| End connections | Weld bevels, forged flanges, clamp hubs, grooved ends |

| Alloy and temper | 5xxx or 6xxx series, tailored to weldability and strength |

| Surface treatment | Anodizing, painting, internal coatings if needed |

| Quality level | Enhanced NDT, documentation, and traceability for critical applications |

The Heavy Duty Aluminum Elbow for Marine Oil and Gas Pipelines combines:

- Corrosion‑resistant marine‑grade aluminum

- Significant weight savings compared with steel

- Robust mechanical performance and weldability

- Flexible configuration for offshore, coastal, and terminal facilities

It is an effective solution for operators who need durable, low‑maintenance pipeline components in aggressive marine conditions while keeping structural loads and installation times under control.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

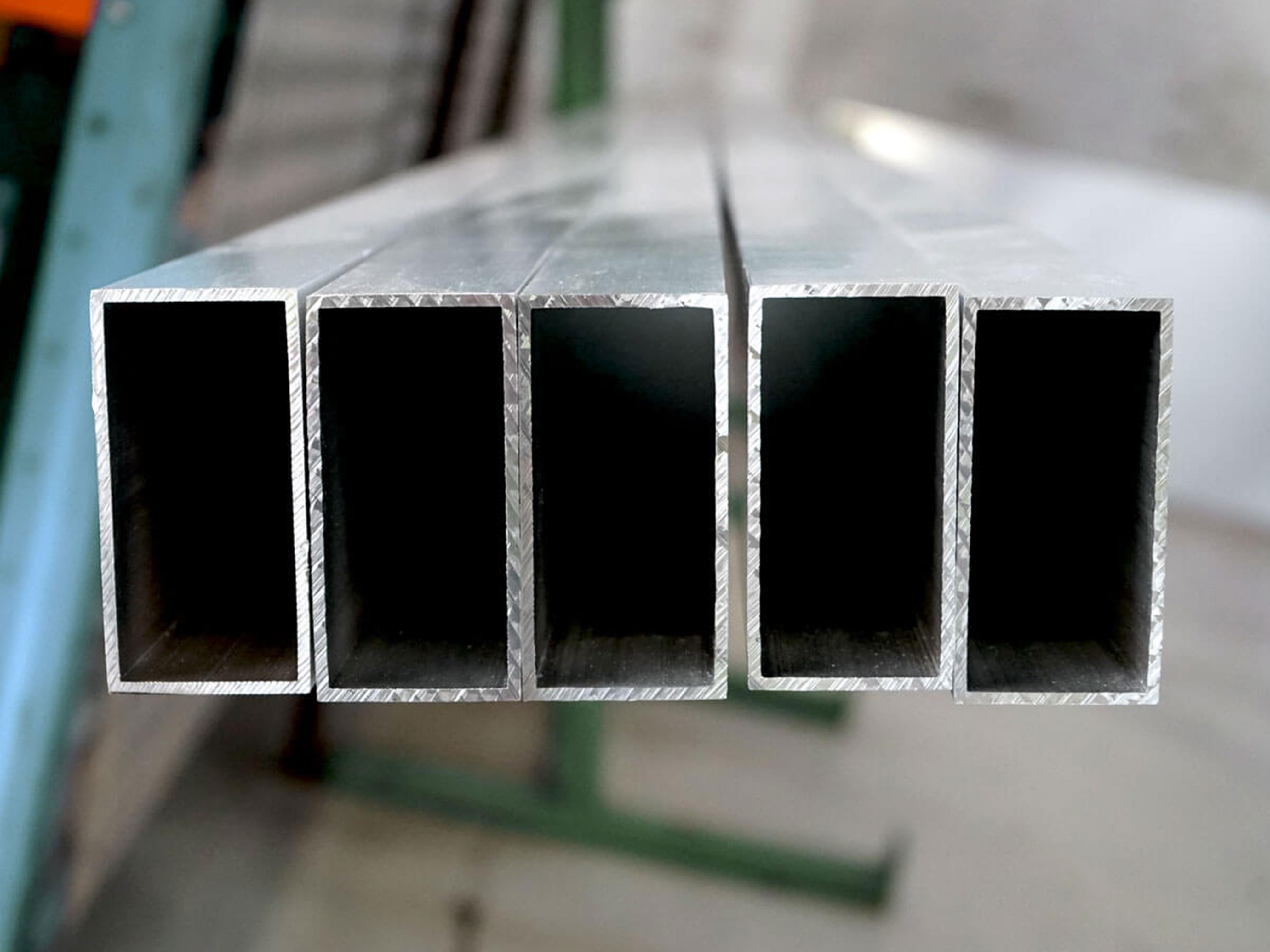

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6061 Marine Aluminum Tubes for Marine Machinery Support Systems

6061 Marine Aluminum Tubes: Essential for Marine Machinery Support SystemsIn the complex machinery and construction of the marine industry, the materials crafted for durability and management play a pivotal role.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View DetailsDurable Marine Aluminum Pipe Elbow for Saltwater Environments

In the world of marine engineering, strength, corrosion resistance, and lightweight characteristics play a pivotal role. As the demand for more resilient and efficient installations surges.

View DetailsAluminum Elbow for Gas and Liquid Transfer on Marine Vessels

Marine vessels operate amidst some of the most challenging environments, where efficiency, durability, and safety of components in fluid transfer systems are paramount.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View DetailsMarine Aluminum Elbow for Fuel System Installations

When it comes to designing and installing fuel systems in marine environments, using the right materials is paramount. Among these materials, Marine Aluminum Elbows is know due to their remarkable properties and advantages.

View Details

Leave a Message