5083 Marine Aluminum Bar for Long Term Marine Equipment Support

Marine applications demand materials that can withstand harsh environments, conduct excellent performance, and provide durability for long-lasting use. One such product that has gained prominence in the marine industry is the 5083 Marine Aluminum Bar. This guide will touch upon its functions, applications, technical details, and much more to provide a complete of this versatile material.

What is 5083 Marine Aluminum?

5083 marine aluminum belongs to the aluminum-magnesium family and is critically praised for its corrosion resistance, strength, and ability to withstand marine conditions. Ideal for building a robust framework in marine equipment, 5083 aluminum bars are trusted across the shipping, fishing, naval, and offshore oil industries.

Functions of 5083 Marine Aluminum Bars

1. Durability

5083 aluminum bars are honeycombed for increased strength while remaining lightweight, making them an ideal structural component in harsh marine settings.

2. Corrosion Resistance

Designed specifically for use in marine applications, its alloying elements resist maritime corrosion—a crucial characteristic benefiting vessels that sail through saltwater environments.

3. Workability

Very well-suited to a range of fabrication methods, 5083 aluminum is easy to transport, handle, and fabricate through cutting, welding, and machining, facilitating project implementations while minimizing overall costs.

Applications of 5083 Marine Aluminum Bars

5083 Aluminum Bars are utilized in various applications across different marine sectors due to their unique properties. Major applications include:

| Applications | Industry |

|---|---|

| Boat Building | Shipbuilding and Yacht Construction |

| Platforms | Offshore Oil Platforms |

| Transportation Cases | Container and Cargo Transport |

| Structural Components | Marine Equipment |

| Support Structures | Marine Dock and Deck Structures |

Technical Details of 5083 Marine Aluminum Bars

The 5083 aluminum alloy exhibits unique properties governed by specific controlled standards in metallurgy.

Specifications

| Property | Value |

|---|---|

| Alloy combination | Al + Mg (metallurgical base) |

| Density | 2.66 g/cm³ |

| Ultimate Strength | ≤ 340 MPa |

| Yield Strength | ≥ 245 MPa |

| Elongation (% min) | 10%-14% |

| Hardness | 60 (Brinell Scale) |

Chemical Composition

the chemical composition is crucial for assessing the material’s properties. The following table outlines the elemental makeup of 5083 marine aluminum.

| Element | Composition Range (% weight) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| chromium (Cr) | 0.05 - 0.25 |

| Silicon (Si) | Not more than 0.4 |

| Iron (Fe) | Not more than 0.4 |

| Zinc (Zn) | Not more than 0.25 |

| Titanium (Ti) | Not more than 0.15 |

Alloy Tempering Conditions

The 5083 aluminum bars undergo specific treatments to enhance mechanical properties. Below are primary tempering conditions to consider:

| Temper Condition | Process Detail |

|---|---|

| O (Annealed) | Soft temper, full annealing |

| H111 | Strain hardened, low-based mechanical property |

| H112 | Strain hardened, good frost resistance |

| H116 | Strain hardened and special tested below the surface for toughness |

Implementation Standards

5083 Marine Aluminum Compliance with various testing categories ensures quality assurance assorted with mechanical handling capabilities; preciseness in conformity certification by standards typically follow:

- ASTM B928M : For pressure vessel applications using aluminum alloys

- SSRC 8176/506.2: Marine guidelines by ship authorities ensuring endurance and performance ashore.

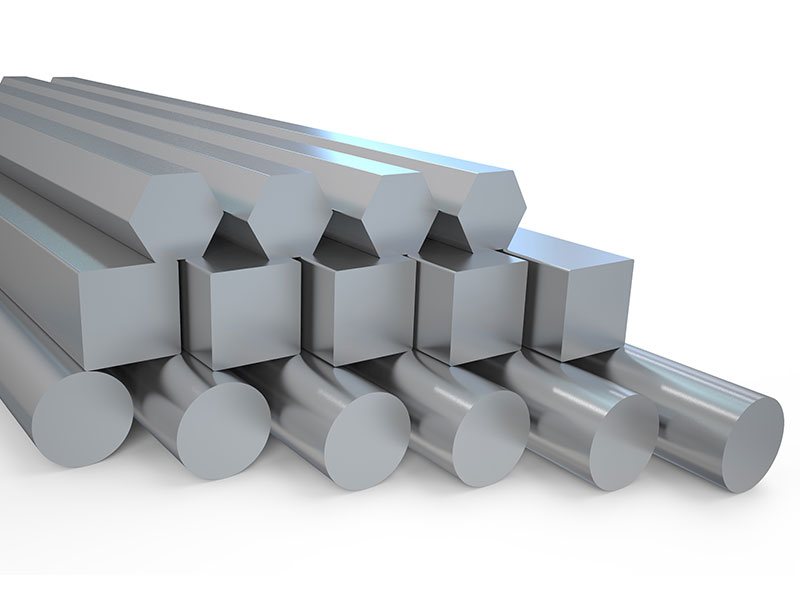

Related Products

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsRelated Blog

5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Grade Aluminum Solid Bar for Offshore Vessel Frame Parts

In the demanding environment of offshore vessels, structural integrity, durability, and corrosion resistance are critical factors that determine overall vessel performance and safety.

View Details5083 Marine Aluminum Bar for Marine Equipment Reinforcements

Superior strength, corrosion resistance, and reliability of 5083 Marine Aluminum Bars, specifically engineered for marine equipment reinforcements. Ideal for harsh sea environments, these aluminum bars offer exceptional mechanical properties and long-term

View Details5083 Marine Aluminum Bar for Long Term Marine Equipment Support

Marine applications demand materials that can withstand harsh environments, conduct excellent performance, and provide durability for long-lasting use. One such product that has gained prominence in the marine industry is the 5083 Marine Aluminum Bar.

View Details5083 Marine Aluminum Bar for Corrosion Resistant Boat Hulls

When considering materials for seafaring vessels, especially boat hulls, durability and resistance to corrosion are of paramount importance. The evolution of marine applications largely banded around revolutionary developments in materials science.

View Details

Leave a Message