Custom shape boat aluminum sheet 5083 h22 h111 h112 h116 h321

In the maritime industry, the need for robust, lightweight, and corrosion-resistant materials is paramount. One material that consistently meets these requirements is Marine Aluminum, particularly in the form of custom shape boat aluminum sheets like the 5083 alloy in various tempers (H22, H111, H112, H116, H321). these unique products, their functions, and applications broadens the horizons for those in boat manufacturing, repair, or customization.

What is Marine Aluminum 5083?

5083 aluminum alloy is part of the 5000 series, recognized for its superior performance in marine environments. Offering excellent corrosion resistance and weldability, it also delivers extraordinary mechanical strength, enabling the construction of durable boat hulls, superstructures, and other essential marine components. The unique temper variations allow manufacturers different properties to suit specific needs.

Temper Variations

The tempering process enhances the physical attributes of the aluminum, and different tempers serve specific applications:

- H22: This temper provides very good strength and moderate resistance to stress-corrosion cracking, making it suitable for pressure vessels and marine architecture where significant high-strength capability is required.

- H111: As a strain-hardened product, H111 is designed predominantly for well-form designs, increasing the application variety but maintaining good weldability and modifiable shapes.

- H112: Like its counterpart (H111), H112 showcases similar mechanical properties with enhanced resistance to cracking despite field welding issues. This temper is often used in high-strength applications.

- H116: This variant presents extraordinary corrosion resistance, adjusted specifically for applications demanding seawater capability such as complete marine vessels and off-shore structures.

- H321: Representing a higher level of corrosion resistance, the H321 temper is ideal when dynamic environments (like extreme saltwater exposure) and lightweight combat realization are advantageous.

Chemical Properties

Knowing the specifications ensures informed material selection. Table 1 outlines the chemical properties of the 5083 aluminum alloy:

| Property | % Composition |

|---|---|

| Aluminum (Al) | 90.7 - 94.7 |

| Manganese (Mn) | 0.40 - 1.0 |

| Magnesium (Mg) | 4.0 - 4.9 |

| Silicon (Si) | 0.40 max |

| Copper (Cu) | 0.10 max |

| Iron (Fe) | 0.40 max |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

Mechanical Parameters and Applications

The corrosion resistive qualities, combined with ample mechanical systems defining Marine Aluminum products, manifest in high-performing attributes ideal for vessel construction:

| Property | H22 | H111 | H112 | H116 | H321 |

|---|---|---|---|---|---|

| Yield Strength | ≥ 260 MPa | ≥ 260 MPa | ≥ 265 MPa | ≥ 270 MPa | ≥ 270 MPa |

| Tensile Strength | ≥ 295 MPa | ≥ 290 MPa | ≥ 295 MPa | ≥ 300 MPa | ≥ 305 MPa |

| Elongation | 15% min afford | 16% min afford | 16% min afford | 14% min afford | 12% min afford |

Functions and Applications

High-strength commercial boats often feature 5083 aluminum designs due to their exceptional fatigue strength and lightweight, thus enabling increased speed and fuel efficiency. Moreover, these sheets are especially teleological for vessels undergoing high-pressure treatments such as ferries, fishing boats, and luxury liners.

Applications:

- Boat Hulls: The structural integrity of the boat is paramount—in transient marine environments, 5083 offers reduced tides over competing materials.

- Decking: H116 treatment guarantees outstanding resistance against fluctuating marine salinity.

- Caging/Retaining Structures: The density setup is accented in H22 delivers added safety in net rail protective solutions.

- Pressure Vessels Equipped for Marina Setup: For containment of liquid containment layers aligned with varying chemical event encounters.

Related Products

Marine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

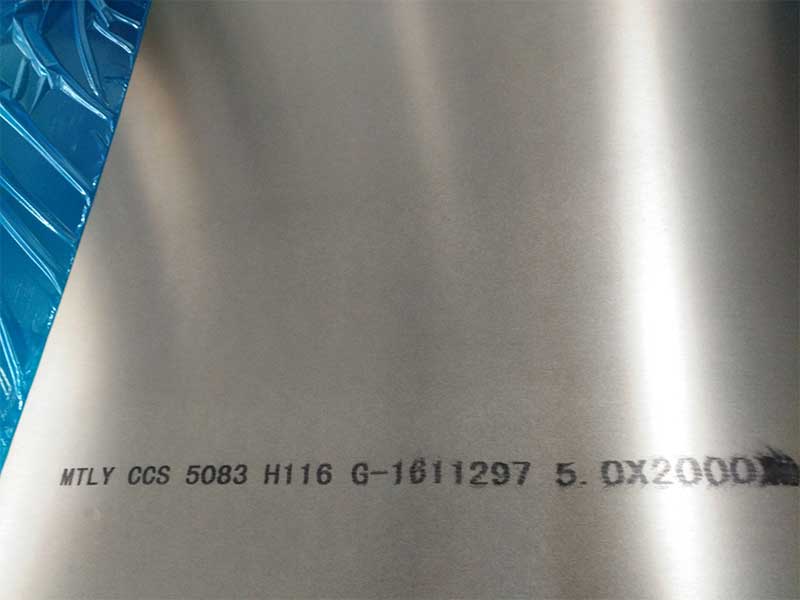

Aluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

View Details2mm 3mm 4mm marine grade 5083 aluminum sheet

When considering materials for marine applications, the demand for durability, adaptability, and weight efficiency comes to the forefront of innovation. One leading solution in this arena is the 5083 aluminum alloy.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View Details

Leave a Message