5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance. Land and marine engineers continuously seek materials that not only withstand high levels of tensile stress, but also endure salinity, humidity, and other challenging conditions present in coastal projects. This is where the customized shapes of 5083 marine aluminum come into play—a game changer in modern construction techniques.

Why Choose 5083 Marine Aluminum for Coastal Structures?

Inherent Properties

5083 aluminum alloy is distinguished among marine metals for its useful set of properties:

- Exceptional Corrosion Resistance: Alloyed with high magnesium and chromium, 5083 offers notable endurance against seawater environmental conditions.

- Excellent Weldability: Ideal for sophisticated constructions, it can be joined using various welding techniques without significant loss of strength.

- High Strength-to-Weight Ratio: Its mechanical properties make it the material of choice when designing with integrity as well as economy.

These attributes lend themselves to structures such as docks, wet storage, marine vessels, gangways, and other permanent infrastructural projects along coastlines.

Custom Shapes: Enhancing Design Flexibility

With the advancement of manufacturing technologies, personalized configurations of 5083 marine aluminum have made their way into standard output. The versatility accompanying customized shapes allows engineers to develop lightweight but strength-tuned components fit for specific applications.

For instance, flanges for improving aerodynamics or girder-like structures uniquely fit for tidal power installations are easier crafted now than ever before, embracing holistic designs in coastal specification scenarios.

Engineering Parameters Customized Around 5083 Malleability

To fully grasp how customized shapes hold up, the following parameters should be considered:

| Property | Value |

|---|---|

| Ultimate Strength (MPa) | 310-340 |

| Yield Strength (MPa) | 235 |

| Elongation (%) | 10%-16% |

| Density (g/cm³) | 2.66 |

| Modulus of Elasticity (GPa) | 73 |

| Thermal Conductivity (W/m·K) | 160 |

| Ratio of Coefficient of Thermal Expansion (x10⁻⁶/°C) | 23 |

| Impact Strength (Notched, J) | Restoration option |

Implementation Standards: PEME Compliance and Beyond

To ensure safety and sustainability in coastal infrastructure development using 5083 aluminum, compliant practices linked with international standards are paramount. This alloy must embody ASTM, AWS, EN, and beyond—such as:

- ASTM B928: Specifications for metals used in corrosive marine environments. Meeting or exceeding ASTM standards signals heightened reliability.

- AWS D1.2: Recommended practices for welding structural applications presenting broad utilization.

Structural engineers initially okviru specifications, conserving integrity while allowing usage post-weld treatments to enhance tempering parameters.

Alloy Temper Characteristics and Variants

5083-O (Soft), 5083-H32 (Quenched & Tempered), and 5083-H116 (Stress-relieved and handled) offer various forging and temperature limits; these behaviors significantly affects implementations.

Through compositions monitoring, understand that H32 formulations excel at marine mooring requirements, suitable economically with ample lifecycle guarantees.

Chemical Composition: Under the Lens of Statute

Deploying high-performance evaluations means examining 5083’s chemical makeup under ISO 1516 standards progressions as seen below:

| Element | Content (% Maximum) |

|---|---|

| Magnesium (Mg) | 4.0-4.9 |

| Manganese (Mn) | 0.4-1.0 |

| Chromium (Cr) | 0.05-0.25 |

| Copper (Cu) | 0.0-0.1 |

| Zinc (Zn) | 0.25 Maximum |

| Iron (fe) | 0.4 permitted |

Undoubtedly every component presents integral value points that benefit exercises for reliable composition vitamins offering intensified protection against environmentally degrading constituents.

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

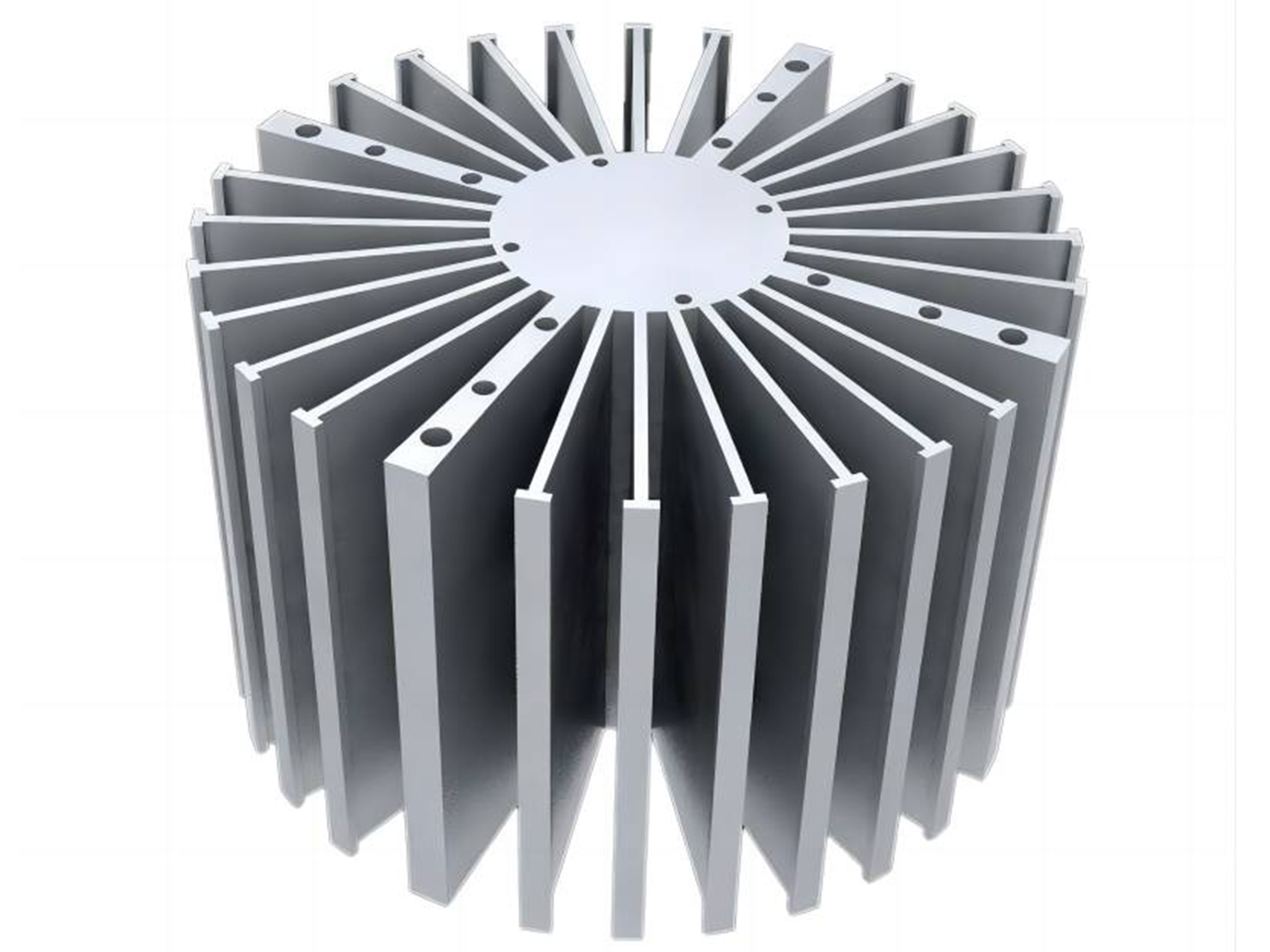

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsRelated Blog

5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View Details5083 Marine Aluminum Customized Shapes for Saltwater Resistant Boat Deck Frames

When it comes to boat deck frames that endure the relentless challenge of saltwater environments, the choice of materials is paramount. Among all options.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

View Details5083 Marine Aluminum Fencing and Railings for Coastal Marine Safety Solutions

When it comes to enhancing safety and durability along coastal infrastructure, selecting the right materials for fencing and railings is paramount. Among the most trusted choices is 5083 marine aluminum.

View Details

Leave a Message