5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

5083 is an aluminum-magnesium alloy (Al-Mg) that is highly resistant to seawater and industrial chemical environments. It is commonly used in boat hulls, shipbuilding, offshore platforms, and marine structures—applications where long-term exposure to salt spray and splash-zone conditions demand materials that will not rapidly corrode. For coastal guardrails and fencing, 5083 offers:

- Superior resistance to pitting and stress-corrosion cracking in chloride environments

- High strength-to-weight ratio for structurally efficient railings and posts

- Good formability for custom ornamental or ergonomic designs

- Excellent weldability for onsite fabrication and repair

- Low maintenance requirements compared to ferrous metals in marine atmospheres

Typical Applications

- Coastal and beachfront pedestrian guardrails and balustrades

- Marina and dock railings, finger piers, and gangways

- Seawall and promenade fencing

- Bridge railings in coastal zones

- Offshore platform handrails, safety barriers, and walkways

- Pool and waterfront barrier systems for saltwater pools and facilities

- Custom architectural railings and decorative fences in marine environments

Functions and Performance Requirements

- Corrosion resistance: Prevents pitting and localized corrosion from chloride ions in seawater and salt spray.

- Structural integrity: Supports live loads, wind loads, and impact loads as required by local building codes.

- Durability & longevity: Minimizes maintenance (no flaking rust, no need for frequent repainting).

- Safety & ergonomics: Smooth surfaces, appropriate heights and spacing to meet safety regulations.

- Aesthetics: Can be anodized or painted (powder coat) for specific architectural finishes.

- Fabrication flexibility: Can be bent, extruded, welded, and machined into complex profiles.

Alloy Composition and Chemical Properties

The following table summarizes the typical chemical composition for 5083 alloy (percent by weight). Composition limits may vary slightly by standard (e.g., ASTM B209, ISO 6361, EN 485), so consult the applicable specification for exact limits.

| Element | Typical Range (wt%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Notes:

- Mg is the principal alloying element that provides solid-solution strengthening and improved corrosion resistance.

- Small additions of Mn and Cr improve strength and grain structure stability.

Mechanical Properties and Temper Conditions

5083 is available in several tempers; for marine fencing and railings the non-heat-treatable, strain-hardened tempers and the annealed temper are most relevant. The Mg content provides strengthening without heat treatment.

| Property | H111 / O / H112 / H32 (typical ranges) |

|---|---|

| Ultimate tensile strength (MPa) | 275 – 345 (depending on temper and thickness) |

| Yield strength (0.2% offset, MPa) | 125 – 290 (temper & thickness dependent) |

| Elongation (%) | 6 – 25 (thinner sections typically higher) |

| Density | 2.66 g/cm³ |

| Modulus of Elasticity | ~69 GPa |

| Brinell Hardness (HB) | ~60 – 95 (temper dependent) |

Common tempers used in fencing & railings:

- O (annealed): maximum ductility, easier forming; lower strength.

- H111 / H112: slightly strain-hardened tempers for good formability and moderate strength.

- H32: strain-hardened and part-annealed for higher strength and good toughness.

Selection tip: Use O or H111/H112 for complex bending or decorative extrusions; use H32 for structural posts and members requiring higher yield.

Standards and Specifications

Materials and fabrication typically reference these standards:

- ASTM B209 — Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B221 — Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B928 / B928M — Standard Specification for Aluminum-Alloy Seamless Pipe and Seamless Extruded Round Tube

- EN 573 / EN 485 — Chemical composition and mechanical properties for aluminum alloys

- ISO 6361 — Aluminum and aluminum alloy sheet and plate

- AWS D1.2 — Structural Welding Code — Aluminum (for welding practices)

- Local building codes for guardrail heights, loads, and infill spacing (e.g., IBC, BS, Eurocodes, or regional standards)

Fabrication: Cutting, Forming, and Joining

- Cutting: 5083 is easily cut with saws, shears, and CNC equipment. Use carbide tooling at appropriate feeds to reduce burrs.

- Forming: Good cold formability; anneal (O temper) for tight bends. For extruded profiles, design for minimum bend radii to avoid cracking.

- Welding: Excellent weldability using GTAW (TIG) and GMAW (MIG) with appropriate filler (commonly ER5356 or ER5183). Pre- and post-weld considerations:

- Use filler metal compatible with 5xxx series (ER5356 for higher strength, ER5183 for improved corrosion resistance in some cases).

- Avoid heat-treatable filler alloys.

- Control distortion with fixturing; use intermittent welds where appropriate.

- Welds in 5083-H116 and similar tempers retain good corrosion resistance but may show slight strength reduction in heat-affected zones.

- Fastening: Stainless steel fasteners (316L recommended) are typical to avoid galvanic corrosion. Isolate dissimilar metals with insulating washers or coatings when necessary.

- Surface Finishes: Mechanical polishing, anodizing (limited for high-Mg alloys; pre-treatment recommended), and powder coating (with appropriate pre-treatment and conversion coatings) are common. Note that high-Mg alloys may show darker anodic colors; consult anodizer.

Corrosion Resistance Details

- 5083 shows excellent resistance to general corrosion and pitting in seawater and to stress corrosion cracking compared to 5xxx alloys with higher magnesium (>5.5%).

- Properly fabricated and coated 5083 guardrails can last decades in salt-spray environments with routine inspection and minimal maintenance.

- Avoid coupling with more noble metals (e.g., copper, brass, or carbon steel unprotected) without insulation to prevent galvanic corrosion. Use compatible stainless-steel fasteners and fittings designed for marine exposure.

Design and Installation Considerations

- Structural sizing: Design posts and rails to meet local load requirements (e.g., 200 lbf concentrated load at top rail or code-required uniform loads). Use engineering calculations or manufacturer load tables.

- Post embedment: For coastal installations, driven or concreted footings must resist uplift, scour, and cyclic wave loading. Corrosion allowances and protective measures for buried sections are recommended (e.g., protective sleeves or coatings).

- Infill options: Vertical balusters, horizontal rails, cable infill (316 stainless wire rope), tempered glass panels with appropriate clamps, or expanded metal inserts. Cable systems require proper tensioning hardware and end fittings.

- Thermal expansion: Allow for thermal movement in long continuous runs via expansion joints or slip connections in rails.

- Maintenance: Periodic rinse with fresh water in high salt environments, inspect welds, fasteners, and coatings. Replace damaged components promptly.

Typical Product Forms and Dimensions

- Extruded handrail profiles, base shoe extrusions, post extrusions, wall-mount brackets, and decorative pickets.

- Tube and pipe for rails and stanchions: 5083 seamless or welded extruded tubes are available in common sizes (e.g., 1"–3" OD or metric equivalents) and wall thicknesses depending on structural need.

- Plate and sheet for brackets and cladding: thicknesses commonly range from 1.5 mm up to 12 mm or higher for heavy-duty applications.

Sample Specification Wording (for project documents)

"Supply and install 5083 aluminum alloy handrails, posts, and fittings per ASTM B221 and ASTM B209. Alloy shall be 5083 with chemical composition conforming to ASTM and EN requirements. All welds shall comply with AWS D1.2 and use ER5356 filler metal (or approved equivalent). Provide finish as after appropriate surface preparation. Fasteners and cable infill to be 316 stainless steel. The system shall resist code-prescribed loads with a minimum 1.5 safety factor."

| Parameter | Value / Notes |

|---|---|

| Alloy | 5083 (Al–Mg–Mn system) |

| Typical Mg | 4.0 – 4.9 wt% |

| Typical Mn | 0.4 – 1.0 wt% |

| Typical Cr | 0.05 – 0.25 wt% |

| Density | 2.66 g/cm³ |

| Modulus of Elasticity | ~69 GPa |

| Yield Strength (0.2%) | 125 – 290 MPa (temper and thickness dependent) |

| Tensile Strength (UTS) | 275 – 345 MPa (typical) |

| Elongation | 6 – 25% (depending on temper/thickness) |

| Temper Options | O, H111, H112, H32 (common) |

| Common Forms | Extrusions, sheets, plates, tubes, bars |

| Welding | Excellent (TIG/MIG); use ER5356 or ER5183 filler |

| Corrosion Resistance | Excellent in seawater / chloride environments |

| Compatible Fasteners | 316 / 316L stainless steel preferred |

| Standards | ASTM B209, B221; AWS D1.2; ISO 6361; EN 485 |

| Typical Surface Finishes | Mill, mechanical polish, powder coat, anodize (limited) |

Advantages vs Alternatives

- Versus stainless steel: 5083 is lighter and typically lower cost; stainless (316) can be stronger and more scratch-resistant but is heavier and can be costlier. Aluminum avoids rust staining and is easier to form and weld.

- Versus mild steel (galvanized): Aluminum eliminates rust formation and long-term maintenance associated with damaged galvanizing; however, steel may be inherently stronger for very high loadings and cheaper for some heavy structural components.

- Versus other aluminum alloys: 5083 offers improved corrosion resistance over many 6xxx series alloys in marine conditions; its non-heat-treatable strengthening mechanism simplifies fabrication and welding.

Installation Best Practices

- Use isolation materials (nylon washers, rubber gaskets) between aluminum and other metals to prevent galvanic corrosion.

- Pre-treat surfaces before powder coating; ensure conversion coating (e.g., chromate or non-chrome alternatives) for adhesion and corrosion protection.

- Design to minimize crevices and water traps where chlorides can accumulate.

- Specify stainless steel fittings and fasteners rated for marine exposure. Consider sacrificial anodes in extremely aggressive environments for buried or submerged components.

- For cable systems, tension and inspect periodically; replace frayed cables immediately.

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

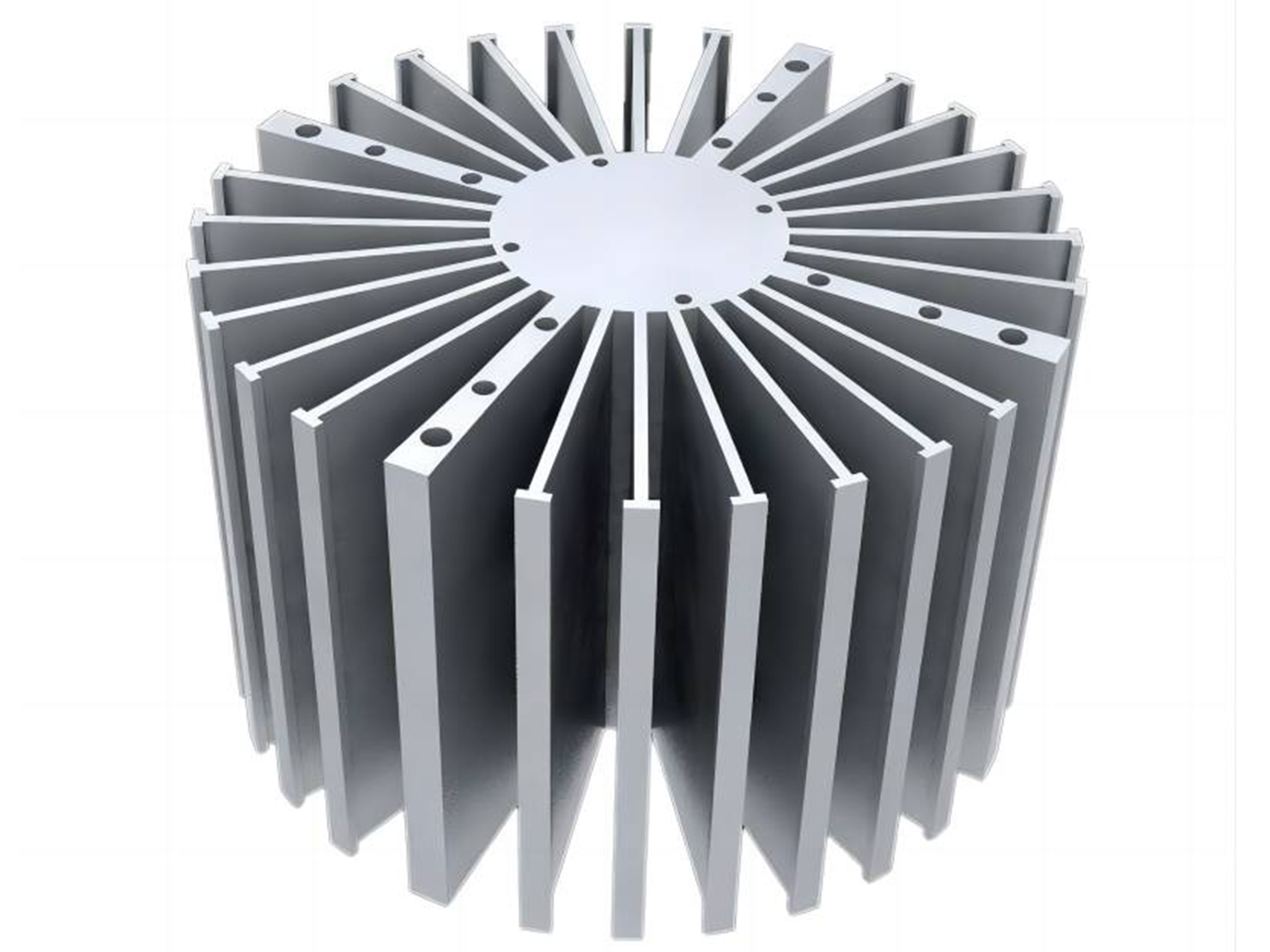

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details5083 Marine Aluminum Fencing and Railings for Coastal Marine Safety Solutions

When it comes to enhancing safety and durability along coastal infrastructure, selecting the right materials for fencing and railings is paramount. Among the most trusted choices is 5083 marine aluminum.

View Details5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details

Leave a Message