5083 Marine Aluminum Customized Shapes for Custom Ship Hull Construction

In the realm of marine engineering, the construction of ship hulls strikes at the foundation of naval architecture and ship integrity. Among the variety of materials available, instead, one alloy has repeatedly distinguished itself as the go-to choice: 5083 marine aluminum. Known for its robust properties, 5083 aluminum is trusted for crafting durable hulls designed to withstand the demands of extreme marine environments while offering design versatility through custom shapes.

Characteristics of 5083 Marine Aluminum

1. Superior Corrosion Resistance

The 5083 aluminum alloy is particularly favored for its exceptional resistance to seawater corrosion, which is essential in maintaining the longevity and structural performance of marine vessels. This resistance is attributed to its specific alloying composition—primarily aluminum, magnesium, and manganese—which generates a protective oxide layer reducing corrosion rates substantially.

2. Strength and Toughness

5083 marine aluminum is characterized by its strength continuum. It is formulated to be solid at various environmental conditions without facing brittleness. This structural integrity makes it ideal for hulls that encounter dynamic loads, waves, and impacts.

3. Lightweight Properties

A significant benefit of using aluminum in ship hull construction is its lightweight nature. By opting for 5083 marine aluminum in customized shapes, shipbuilders can significantly reduce the overall weight of the hull. This results in better fuel efficiency during cruising and allows for heavier cargo capacity.

4. Versatility in Design

One of the distinct advantages of 5083 aluminum is its workability, which allows for the creation of customized shapes tailored to specific design requirements. For intricate vessel designs, materials can be anodized, trimmed, cut, or shaped in ways that mold directly to naval constructions without compromising on integrity.

Applications in Custom Ship Hull Construction

Owning their remarkable properties, 5083 marine aluminum can be adapted for various applications in ship hull construction, including but not limited to:

- Fishing Vessels: Applications focus on corrosion resistance for sustainability in ocean environments, embodied in both designs and functionality.

- Workboats and Tugboats: Heavy-duty shapes and configurations adapted to increase stability under load and maintain operational efficiency.

- Luxury Yachts: A primary allure beyond durability; the aesthetic flexibility facilitates unique designs, perfectly molded to customer desires and trends in yacht motifs.

Technical Parameters and Properties of 5083 Marine Aluminum

Chemical Composition Table:

| Element | Wt% |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.40 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Zinc (Zn) | ≤0.25 |

| Titanium (Ti) | ≤0.15 |

Mechanical Properties Table:

| Property | Value (T6 Temper) |

|---|---|

| Yield Strength | 260 MPa |

| Ultimate tensile strength | 310 MPa |

| Elongation | 8-12% |

| Hardness (Brinell) | 90-100 |

Tempering & Implementation Standards

Referring to union norms such as the American Society for Testing and Materials (ASTM B928) and International Maritime Organization (IMO) protocols, customization involves taking alloy tempering seriously. Various formations denote temper state (F, H, H321)—with H116 being earmarked for aluminum looking at the marine exposure to enhance corrosion resistance.

Related Products

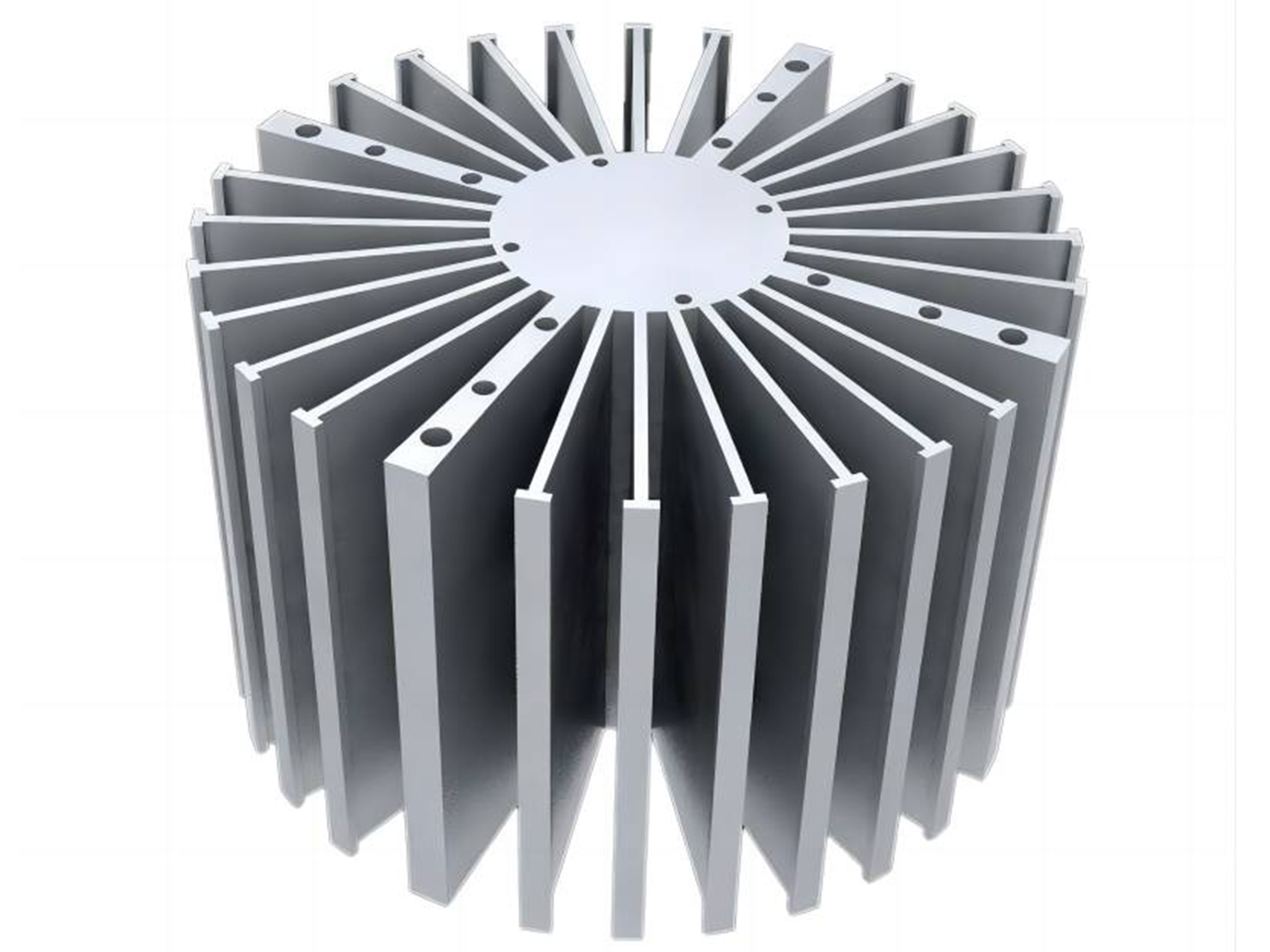

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details5083 Marine Aluminum Customized Shapes for Custom Ship Hull Construction

In the realm of marine engineering, the construction of ship hulls strikes at the foundation of naval architecture and ship integrity. Among the variety of materials available, instead, one alloy has repeatedly distinguished itself as the go-to choice.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5083 Marine Aluminum Fencing and Railings for Coastal Marine Safety Solutions

When it comes to enhancing safety and durability along coastal infrastructure, selecting the right materials for fencing and railings is paramount. Among the most trusted choices is 5083 marine aluminum.

View Details

Leave a Message