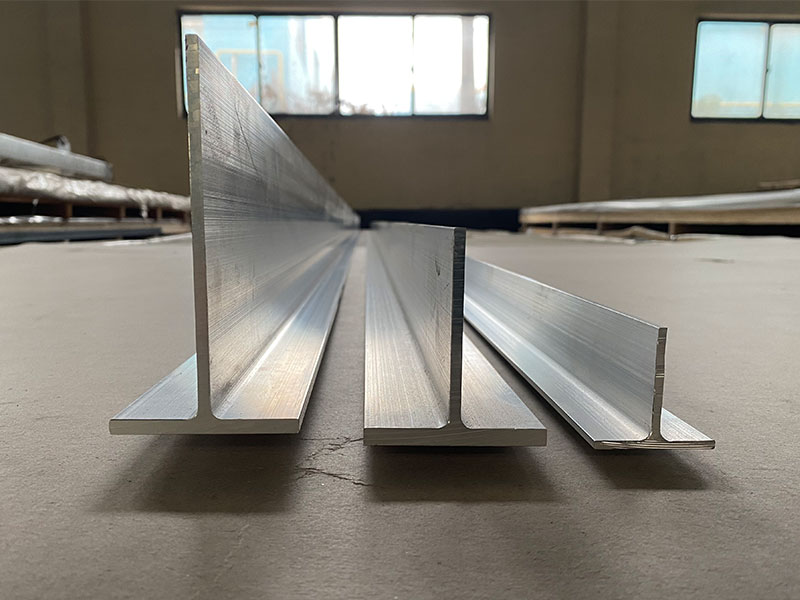

6061 Marine Aluminum Channels for Offshore Boat and Platform Construction

6061 Marine aluminum channels are a premier choice for offshore boat and platform construction owing to their combination of strength, corrosion resistance, and excellent workability. Designed specifically for harsh marine environments, these channels provide structural integrity and longevity, ensuring safety and performance in severe offshore conditions.

6061 is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements. When shaped into channels, this metal profile is especially favored in marine structures like boats, sea platforms, and dock systems due to its lightweight nature combined with resilience against saltwater corrosion.

Features

- Superior Corrosion Resistance: Treated aluminum with enhanced resistance to saltwater and other oxidative elements common in marine environments.

- High Strength-to-Weight Ratio: Offers excellent mechanical strength without adding unnecessary weight, critical for buoyancy and performance in marine vehicles and constructions.

- Good Weldability: Supports various joining methods including TIG and MIG welding, which facilitates custom fabrication on site or in workshops.

- Outstanding Durability: With a solid medium-tensile strength and excellent fatigue resistance, 6061 channels endure repeated stress and harsh environmental conditions.

- Versatile Machinability: Easily machined and formed to desired profiles without compromising the metal's structural integrity.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

Note: Limits represent typical ranges for 6061 aluminum alloy per ASTM B221 standards.

Technical Specifications

| Property | Value |

|---|---|

| Standard | ASTM B221, AMS-QQ-A-250/5 |

| Temper | T6 (Solution heat-treated & artificially aged) |

| Density | 2.70 g/cm³ |

| Ultimate Tensile Strength | 290 MPa (42,000 psi) |

| Yield Strength (0.2% offset) | 241 MPa (35,000 psi) |

| Elongation at Break | 10 – 17% (depends on thickness) |

| Melting Point | 582 – 652°C (1,080 – 1,205°F) |

| Thermal Conductivity | 166 W/m*K |

| Electrical Conductivity | 40 – 45% IACS |

| Modulus of Elasticity | 68.9 GPa |

Applications in Offshore Boat and Platform Construction

6061 Marine aluminum channels serve numerous critical roles in marine construction due to their balance of lightness, strength, and corrosion resistance:

- Structural Frames: Used in constructing hull frames, decks, and support ribs that require excellent mechanical strength and stability.

- Chassis and Superstructure: Ideal for building light-yet-rigid superstructures and mainframe components for offshore utility engines and housed equipment.

- Marine Platform Modules: Integral for infrastructure on offshore oil rigs and wind farm support platforms where large, robust profiles are pivotal.

- Accommodating Environmental Loads: These channels absorb wave impact and wind loads effectively, ensuring offshore structures maintain integrity under extreme forces.

- Custom Brackets and Braces: Adapt rapidly to varying site needs for brackets, braces, and reinforcements associated with piping and mechanical system installations.

- Corrosion-Proof Exhaust and Vent Stacks: Applied to vent stacks that face constant salt spray, Petrochemical corrosion risks, and UV exposure.

Why Choose Our 6061 Marine aluminum channels?

Our 6061 Marine aluminum channels are manufactured through rigorous casting and extrusion standards meeting strict aerospace and marine modular longevity requirements. We offer customizable dimensional profiles, precision tolerance control, and additional anodizing or marine-grade powder coatings to boost corrosion defense further.

Certified to international quality frameworks, resulting 6061 channels guarantee a reliable, sustainable, and maintenance-friendly building platform for all critical factory-made or custom-manufactured marine constructions.

For inquiries on specific dimensions, custom fabrication, or bulk order quotes, please contact our engineering support team. We provide unmatched expertise to support your marine engineering and construction demands with premium Aluminum Alloy solutions.

Related Products

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsRelated Blog

6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details6061 Marine Aluminum I Beams for High Performance Marine Engineering

The 6061 marine aluminum I beams are a premier choice for engineers and designers in the marine industry. Renowned for their strength, corrosion resistance, and versatility, these aluminum I beams are ideal for various applications.

View Details

Leave a Message