5052 Marine Aluminum Tubes for Heavy Duty Marine Structures

In heavy-duty marine structures, 5052 marine aluminum tubes occupy a very particular niche: they are not the strongest alloy in the shipyard, but they often become the most reliable part of the system when saltwater, vibration, and long-term maintenance are all considered together. Seen from the perspective of “lifecycle resilience” rather than just static strength, 5052 reveals why so many naval architects and marine engineers specify it for tubes, conduits, and structural frames in corrosive marine environments.

Why 5052 Tubes Excel in Heavy-Duty Marine Structures

From a mechanical design standpoint, heavy-duty marine structures live at the intersection of multiple constraints: wave-induced vibration, impact loading, continuous salt spray, galvanic interactions with other metals, and the practical reality of onboard fabrication and repair. When those constraints are weighted equally, 5052 aluminum tubes emerge as a balanced solution.

Rather than chasing maximum tensile strength, 5052–especially in tube form–prioritizes:

- High resistance to general and pitting corrosion in seawater

- Excellent ductility for bending, flaring, and forming complex tube routes

- Good fatigue resistance under cyclic loading, especially when welds are involved

- Weldability without significant hot cracking risks

- A favorable strength-to-weight ratio for structural elements that must remain light but rugged

For heavy-duty marine applications such as offshore platforms, patrol boats, deck support frames, catwalk handrails, davits, radar masts, piping protections, and structural guards, these characteristics often outperform “harder” but more brittle or corrosion-prone alloys.

The Metallurgical Basis: Mg-Rich, Mn-Stabilized, Non-Heat-Treatable Alloy

5052 belongs to the 5xxx series, a family of aluminum–magnesium alloys specifically valued for marine service. It is a non-heat-treatable alloy, meaning it gains its strength through cold work (strain hardening) rather than age-hardening heat treatment.

From a distinctive viewpoint, 5052’s reliability in tubes comes from three metallurgical behaviors:

- Magnesium in the solid solution significantly increases corrosion resistance in chloride environments while modestly boosting strength

- Manganese assists in grain refinement and helps stabilize microstructure, improving toughness and uniformity

- The absence of significant copper content sharply reduces susceptibility to galvanic corrosion in seawater

In practice, that microstructural simplicity translates to predictable behavior under welding, forming, and long-term salt exposure—critical for tubular sections that see complex loading states.

Chemical Composition of 5052 Marine Aluminum Tubes

Below is a typical chemical composition range for marine-grade 5052 aluminum, expressed in weight percent. Actual production values follow relevant standards such as ASTM B241/B241M, ASTM B345/B345M or EN equivalents.

| Element | Typical Content (wt%) | Functional Role in Marine Tubes |

|---|---|---|

| Mg | 2.2 – 2.8 | Primary strengthening; to seawater corrosion resistance |

| Mn | ≤ 0.10 | Grain refinement, stability, improves toughness |

| Cr | 0.15 – 0.35 | Stress corrosion resistance; stabilizes Mg distribution |

| Fe | ≤ 0.40 | Impurity; controlled to maintain formability and toughness |

| Si | ≤ 0.25 | Impurity; excessive levels can impair welding |

| Cu | ≤ 0.10 | Minimized to enhance marine corrosion resistance |

| Zn | ≤ 0.10 | Controlled to avoid SCC and galvanic issues |

| Others (each) | ≤ 0.05 | Trace impurities only |

| Others (total) | ≤ 0.15 | Aggregate limit on all other elements |

| Al | Balance | Matrix metal; defines overall properties |

This composition is tailored for marine environments: high magnesium, low copper, controlled impurities. For tubes used in heavy-duty structures, that chemistry provides a robust platform for welding and cold work without sacrificing corrosion performance.

Alloy Tempers for Marine Tubular Structures

Because 5052 is strengthened by cold working, temper choice directly defines how a tube will behave when you bend it, weld it, or load it repetitively at sea. For heavy-duty marine structures, four tempers dominate the design space.

O (Annealed)

Extremely soft, maximum ductility, minimal strength. Rarely used as the final temper in heavy-duty structures but valuable when significant post-forming of tubes is needed. Often an intermediate stage before strain hardening.H32 (Strain-hardened and then stabilized)

A very common temper in marine sheet, and occasionally used in tube stock when a balance of moderate strength and high ductility is required. Good for moderately loaded tubular frameworks, bent rails, and protective guards.H34 (Strain-hardened slightly more than H32)

Offers higher strength with slightly reduced ductility. Suitable for tubes that require better load-carrying capacity but still need reliable formability and weldability. Frequently used in stanchions, tubular trusses, and bracing.H36 / H38 (Higher degrees of strain hardening)

These tempers provide further strength increases at the cost of formability. Designers may specify them for straight, lightly formed structural tubes where higher static capacity is needed and bending operations are limited or carefully controlled.

From a lifecycle perspective, choosing a temper that is slightly “softer” than the maximum possible strength often delivers better real-world durability: improved notch toughness, better response to vibration, and more tolerant behavior at welded joints.

Mechanical Properties: Linking Numbers to Real Marine Loads

Typical mechanical properties for 5052 tubular products in commonly used marine tempers are outlined below. These are reference values; actual tested values depend on product standard and tube dimensions.

| Property | 5052-O | 5052-H32 | 5052-H34 |

|---|---|---|---|

| Tensile Strength (MPa) | ~193 | ~228 | ~262 |

| Yield Strength (0.2% MPa) | ~89 | ~152 | ~193 |

| Elongation (50 mm gauge) | ~25–30% | ~12–18% | ~10–16% |

| Brinell Hardness (HBW) | ~47 | ~60 | ~70 |

| Modulus of Elasticity (GPa) | ~70 | ~70 | ~70 |

| Density (g/cm³) | ~2.68 | ~2.68 | ~2.68 |

Translating these numbers into structural terms:

- The modulus remains constant, so stiffness comes mainly from tube geometry (diameter and wall thickness)

- Yield strength in the H3x tempers is ample for heavy-duty frames that prioritize light weight over extreme strength

- High elongation values ensure energy absorption and ductile failure behavior, vital in impact scenarios such as mooring loads, fender strikes, and wave slam

Dimensional Parameters for Heavy-Duty Marine Tubes

In heavy-duty marine frameworks, tube sizing is as strategic as alloy selection. 5052 tubes can be supplied in a wide spread of dimensions, adapted to local and international standards.

Common dimensional considerations include:

Outside Diameter (OD)

Small-diameter tubes are widely used for cable conduits, guardrails, hydraulic line protection, and lightweight trusses. Larger OD tubes form primary frames, crossbeams, and mast sections.Wall Thickness

Thinner walls minimize weight but must still handle compressive buckling, local denting, and fatigue. Heavier walls are used in high-load locations such as connection nodes, foundation interfaces, and regions exposed to impact or abrasion.Length and Straightness

For offshore modules and ship superstructures, long, straight extruded tubes simplify installation and reduce coupling joints. Straightness tolerances are critical where alignment of bolted or welded frames depends on tubular accuracy.Ovality and Dimensional Tolerances

High-precision tolerances ensure proper fit-up in sleeve joints, flanges, and welded nodes. Excessive ovality complicates automated welding and can introduce residual stresses.

In a design optimized for corrosion and fatigue, engineers often oversize the tube diameter and modestly increase wall thickness compared to land structures, leveraging aluminum’s low density to maintain a favorable weight profile.

Implementation Standards and Certification Pathways

For marine aluminum tubes made from 5052 alloy, several established standards govern chemical composition, mechanical performance, and dimensional tolerances. While the exact standard selected depends on region and application, the following frameworks are widely used or cross-referenced in heavy-duty projects:

ASTM B241/B241M

Covers seamless aluminum and aluminum-alloy pipes and seamless extruded tubes; frequently referenced for structural and pressure-related tubular applications.ASTM B345/B345M

Specifically addresses drawn seamless aluminum-alloy tubes; used when tighter dimensional and surface finish requirements are specified.EN 755 series

European standards for extruded aluminum and aluminum alloy products (including tubes), with detailed dimensional and mechanical requirements.ISO 6362 / ISO 6361 series

International standards for wrought aluminum products, guiding composition and properties for extrusions and tubes.Classification Society Rules

For heavy-duty marine structures in classed vessels or offshore units, 5052 tubes and their production processes frequently align with the requirements of DNV, ABS, Lloyd’s Register, BV, or CCS. These rules may specify additional testing, weld procedure qualifications (WPS/PQR), and inspection regimes.

Compliance with such standards ensures that the chemistry and mechanical performance tables supplied by the manufacturer reliably translate into on-site behavior, allowing naval architects to design with confidence.

Corrosion Behavior in Real Marine Environments

The true value of 5052 tubes emerges after years in service. In a seawater environment, magnesium-rich 5xxx alloys like 5052 form a stable oxide film that resists both uniform and localized pitting. The low copper content is crucial here: it minimizes micro-galvanic cells that would otherwise accelerate attack.

A few field-relevant behaviors stand out:

Resistance to Seawater Pitting

5052 withstands continuous salt spray and immersion better than many high-strength heat-treatable alloys. For tubular systems exposed to splash zones, decks, and piping enclosures, this is a major advantage.Good Performance Under Coatings

When coated or anodized, 5052 provides an excellent substrate, reducing the risk of underfilm corrosion or blistering. Tubes used in visible superstructures often leverage this to maintain appearance as well as integrity.Reduced Risk of Stress Corrosion Cracking

Compared with high-strength 7xxx series, 5052 has a much lower tendency toward stress corrosion cracking, especially in welded, cold-worked tubes subjected to sustained loads.Galvanic Compatibility

While galvanic corrosion cannot be entirely eliminated in mixed-metal systems, 5052 performs well when joined with compatible alloys and stainless steels using proper isolation practices and coatings.

From a maintenance viewpoint, this means fewer unplanned repairs, reduced inspection intervals, and longer service life for tubular frameworks and supports.

Weldability and Structural Joint Integrity

Tubes in marine structures are rarely isolated pieces; they are networks of welded intersections, gussets, and reinforcement sleeves. Here, 5052’s non-heat-treatable nature becomes a practical advantage.

aspects of weld behavior include:

- Excellent weldability with common filler metals such as ER5356

- Minimal hot cracking tendencies compared with some high-copper or high-zinc alloys

- Retention of good corrosion resistance in the heat-affected zone, especially when properly cleaned and protected

- Predictable loss and redistribution of strength around welds (designers often consider the joint efficiency and adjust wall thickness or bracing accordingly)

For tubular trusses, frames, and masts, this means that load paths can be confidently routed through welded intersections without resorting to excessively heavy joint reinforcements.

Formability: Curved Geometry Without Compromising Integrity

Marine structures are increasingly adopting organic, curved geometries to improve aerodynamics, aesthetics, and functionality. Tubes must bend without cracking, flattening, or wrinkling—especially important for railings, ladder hoops, protective cages, and integrated equipment supports.

In tempers like H32 and even H34, 5052 offers:

- High allowable bend radii with minimal risk of fracture

- Stable cross-sectional shape under proper bending procedures

- Good compatibility with mandrel bending, rotary draw bending, and roll bending

This formability allows designers to specify custom tube paths around complex equipment layouts, deck penetrations, and hull curvature, while still meeting strength and corrosion requirements.

Thermal and Physical Properties in Service

Heavy-duty marine structures do not only see mechanical loads; they also encounter wide temperature swings, solar heating, and occasionally cryogenic or near-freezing conditions.

Relevant thermal and physical properties for 5052 tubes include:

- Thermal Conductivity: approximately 138 W/m·K

- Coefficient of Thermal Expansion: around 23.8 × 10⁻⁶ /K

- Melting Range: roughly 607–649 °C

These values mean that 5052 tubes expand and contract predictably with temperature, an important factor in long tubular runs or mixed-material joints. The relatively high thermal conductivity also helps dissipate localized heat from solar exposure or process piping, reducing thermal gradients and associated stresses.

Design Strategies: Using 5052 Tubes as a System, Not Just a Material

Looking at 5052 tubes not as isolated products but as part of a systems approach to marine structure design can significantly enhance performance:

- Combine 5052 primary tubes with compatible 5xxx and 6xxx alloys in brackets and fittings to harmonize corrosion behavior

- Position welds away from peak stress regions in tubular frames, exploiting the alloy’s formability to route tubes more favorably

- Use anodizing or high-performance marine coatings to extend already good corrosion resistance, especially in splash and tidal zones

- Leverage the inherent ductility to design for controlled deformation under extreme loads, preserving the overall integrity of the structure

A system built around 5052 tubes often weighs less than an equivalent steel structure yet achieves comparable operational robustness in many marine contexts.

Related Products

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

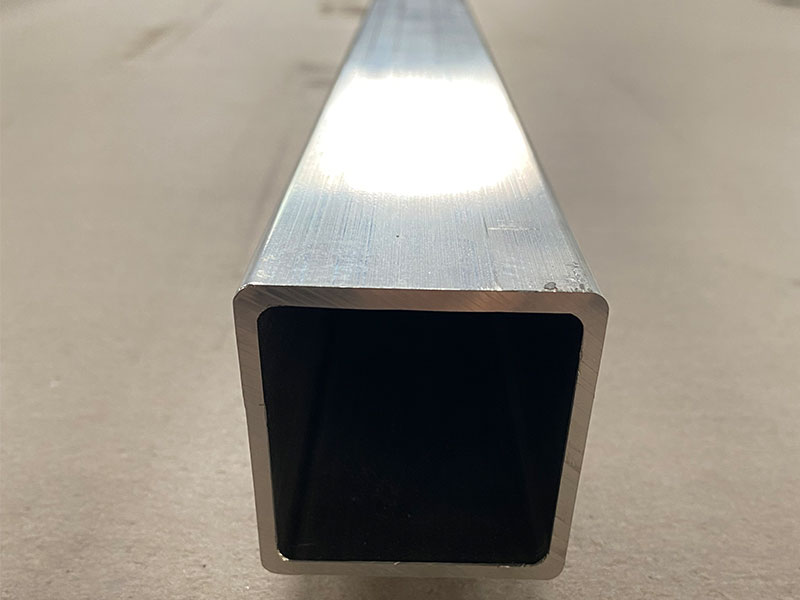

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Tubes for Boat and Ship Building

Marine aluminum has proven to be an ideal material for boat and ship building due to its property of being lightweight, corrosion-resistant, and high strength. Among the various alloys available.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Structures

In heavy-duty marine structures, 5052 marine aluminum tubes occupy a very particular niche: they are not the strongest alloy in the shipyard, but they often become the most reliable part of the system when saltwater, vibration.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for High Performance Boat Structures

When it comes to high-performance boat structures, the strength, weight, and durability of materials matter enormously. One of the most favored materials in the marine industry is **5052 Marine Aluminum Tubes.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details

Leave a Message