6061 Marine Aluminum I Beams for High Performance Marine Engineering

The 6061 marine aluminum I beams are a premier choice for engineers and designers in the marine industry. Renowned for their strength, corrosion resistance, and versatility, these aluminum I beams are ideal for various applications, including shipbuilding, marine structural components, and other high-performance marine engineering projects.

Features of 6061 Marine Aluminum I Beams

Corrosion Resistance: 6061 aluminum contains elements that provide excellent resistance to corrosion, making it suitable for harsh marine environments.

Strength-to-Weight Ratio: These I beams offer an outstanding mix of high tensile strength and lightweight properties, resulting in reduced overall structure weight without sacrificing performance.

Versatility: The adaptability of 6061 aluminum allows for various shapes and configurations, enabling tailored solutions to specific engineering challenges.

Weldability: The alloy is highly weldable, easing the assembly process, allowing for enhanced disassemblability and modification.

Malleability: Aluminum I beams can be easily processed into various sizes, providing flexibility in design specifications.

Chemical Composition

the chemical makeup of 6061 aluminum I beams is crucial for comprehending their performance metrics. Below is the typical alloy composition:

| Element | Chemical Symbol | Composition (wt.%) |

|---|---|---|

| Aluminum | Al | 97.9 - 98.7 |

| Silicon | Si | 0.40 - 0.80 |

| Iron | Fe | 0.70 max |

| Copper | Cu | 0.15 - 0.40 |

| Manganese | Mn | 0.15 - 0.80 |

| Magnesium | Mg | 0.8 - 1.2 |

| Chromium | Cr | 0.04 - 0.35 |

| Zinc | Zn | 0.25 max |

| Titanium | Ti | 0.15 max |

Technical Specifications

The performance of the 6061 marine aluminum I beams can further be evaluated through the technical specifications. The following table summarizes physical and mechanical parameters:

| Property | Unit | Value |

|---|---|---|

| Density | g/cm³ | 2.70 |

| Yield Strength | MPa | 240 |

| Ultimate Tensile Strength | MPa | 310 |

| Elongation (at break) | % | 20 |

| Modulus of Elasticity | GPa | 69 |

| Melting Point | °C | 580 |

| Conductivity | % IACS | 30-50 |

| Thermal Conductivity | W/m·K | 160 |

Applications

Given their excellent performance characteristics, 6061 marine aluminum I beams are utilized in a range of marine and industrial applications, such as:

Shipbuilding: Incorporating I beams into hull construction and deck systems, contributing to overall strength while minimizing weight.

Fishing Vessels: Used in motto and trawl designs for structural support, maintaining durability under wave forces.

Hydraulic Structures: Ideal for fabrication of gates and levee systems due to their corrosion-resistant properties.

Support Railing Systems: The aesthetic appeal coupled with resilience makes 6061 I beams ideal for marine staircases and railings.

Floating Platforms: Preferred material for the framework and stability of floating docks or pontoons in marinas.

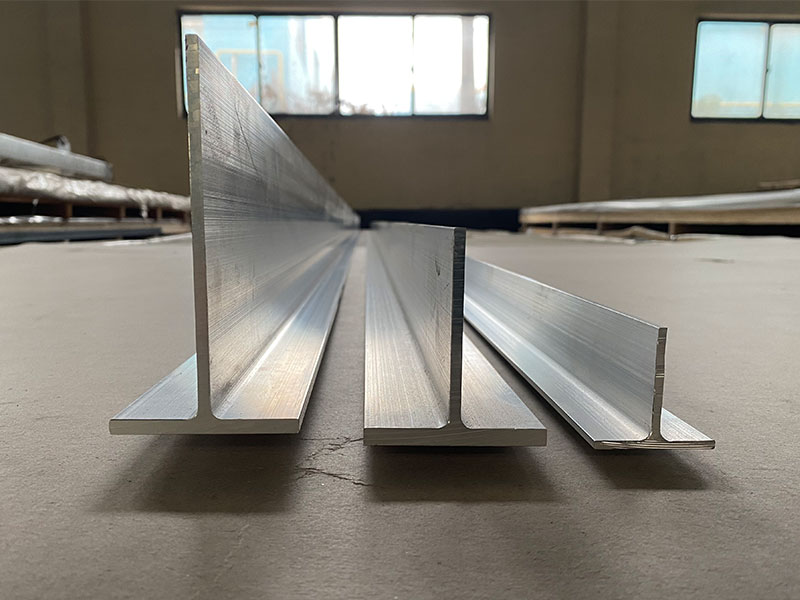

Related Products

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsRelated Blog

6061 Marine aluminum angles

6061 Marine Aluminum Angles are among the most popular and versatile aluminum alloy products used in marine and structural engineering applications. Renowned for their excellent strength, corrosion resistance, and machinability.

View Details6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details6061 Marine Aluminum Z Shaped Sections for High Strength Boat Reinforcement

6061 Marine Aluminum Z Shaped Sections are purpose-designed extrusions used for structural reinforcement in marine and offshore applications. Made from 6061 aluminum alloy and formed into Z-profile sections, these members combine high strength.

View Details

Leave a Message