6061 Marine Aluminum Hexagonal Bars for Boat Hull and Frame Assembly

6061 Marine aluminum hexagonal bars are engineered to deliver exceptional strength, corrosion resistance, and machinability for marine applications. Used widely in boat hull and frame assembly, these bars combine the premium qualities of the 6061 alloy with the specialized hexagonal shape, enabling easy fabrication and structural integration.

6061 aluminum is an alloy known for its robust mechanical properties, excellent corrosion resistance, and versatility, making it a top choice in the marine industry. When formed into hexagonal bars, 6061 Marine Aluminum becomes especially beneficial for complex structural components requiring multi-planar joining, splicing, or anchoring.

Features

- High Corrosion Resistance: Thanks to a robust oxide film and added magnesium, the alloy withstands harsh marine environments.

- Superior Strength-to-Weight Ratio: Offers notable mechanical strength while retaining lightweight properties,lengthening service life without added bulk.

- Excellent Weldability and Machinability: Compatible with modern fabrication processes allowing precise and seamless structural joints.

- Robust Fatigue Resistance: Suitable for components subject to cyclic loads such as hull frames and joints.

- Hexagonal Geometry: Simplifies gripping, fastening, and assembly in configurations where flat surfaces speed up manufacturing operations.

Chemical Composition of 6061 Marine Aluminum Alloy (% by weight)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| Percentage | 0.4–0.8 | 0.7 max | 0.15–0.4 | 0.15 max | 0.8–1.2 | 0.04–0.35 | 0.25 max | 0.15 max | Balance |

This precise chemical balance ensures excellent marine-grade corrosion resistance combined with optimal mechanical properties.

Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength (MPa) | 280 - 310 | ASTM B221 |

| Yield Strength (MPa) | 240 - 260 | ASTM B221 |

| Elongation (%) | 8 - 12 % | ASTM B211 |

| Hardness (Brinell) | 95 - 105 | ASTM E10 |

| Density (g/cm³) | 2.70 | - |

| Fatigue Strength (MPa) | ~137 | ASTM E466 |

Technical Specifications for 6061 Marine aluminum hexagonal bars

| Specification | Details |

|---|---|

| Alloy Grade | 6061 |

| Shape | Hexagonal Bars |

| Bar Size (Width across flats) | 10mm to 150mm (custom sizes available) |

| Length | Standard 6 meters or as specified |

| Temper | T6 (solution heat-treated & artificially aged) |

| Surface Finish | Mill finish or anodized marine grade finish available |

| Compliance | ISO 9001, ASTM, AMS specifications suitable for marine use |

Applications

6061 Marine aluminum hexagonal bars are highly tailored for multiple structural marine applications, including:

- Boat Hull Assemblies: Form major supportive rectangular/square cross-section structural framework combining lightweight strength and corrosion resistance.

- Frame Assembly: Used in framing keel supports, ribs, longitudinal and transverse supports exhibiting fatigue and stiffness merits.

- Marine Railings and Fixtures: Friendliness to precision cutting allows fabrication of rail mounts and connector rods directly incorporated into built-up assemblies.

- Mooring and Anchoring Devices: Facilitates corrosion resistant foundation and lourd-bearing brackets exposed to water exposure.

- Custom Hardware Manufacturing: Ideal for machining into bushings, sleeves, and fasteners where dimensions and longevity are critical performance drivers.

Benefits to Marine Industry Applications

- Long-term Corrosion Protection: Ensures long-lasting structural integrity even in saltwater or alkaline water settings.

- Reduced Maintenance Cycles: Machines and phases with outstanding fatigue properties reduce downtime for coatings or welding repairs.

- Lightweight Design Innovations: Promotes improved vessel speed efficiency and fuel economy through weight savings.

- Highly Adaptable: Besides pre-fab components, hexagonal bars improve construct options in various joining systems for modular build solutions.

- Cost Efficiency: Durable service life paired with Portland shaped column profiles minimizes metal waste and increases throughput risk reduction.

The combination of 6061 Marine Aluminum Alloy with a hexagonal bar profile presents a streamlined solution tailored to boat manufacturers and marine fabricators seeking dependable pervasive strength, corrosion resistance, and precision joinery capabilities. Backed by recognized material performance standards, 6061 Marine aluminum hexagonal bars provide the ideal base for structural components and specialized assemblies—enhancing build quality and marine endurance at scale.

For customized size requirements, standards compliance, or application consultations, please contact our engineering team for detailed technical support.

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

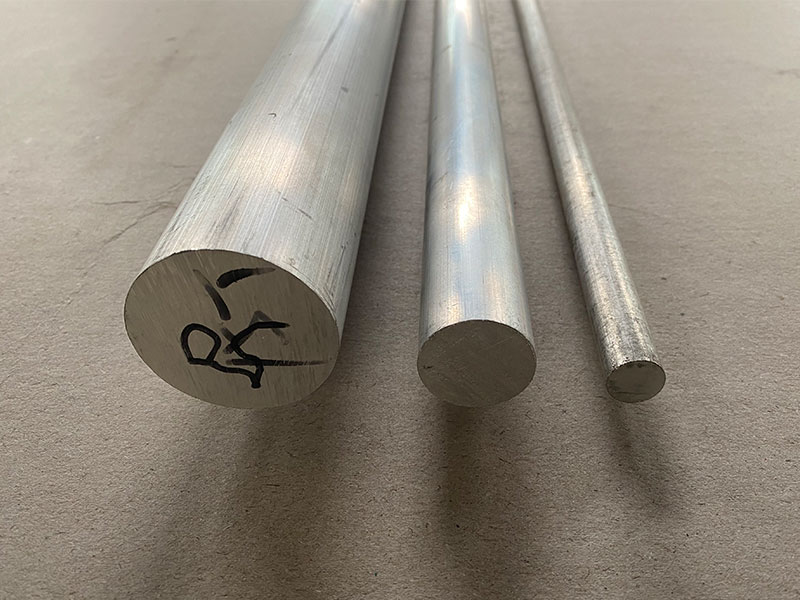

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6061 Marine Aluminum Hollow Bars for Custom Boat Hull Parts

6061 Marine Aluminum Hollow Bars are a popular choice in the marine industry, recognized for their excellent mechanical properties and corrosion resistance. This specific alloy provides the ideal balance of strength and lightweight construction.

View Details6061 Marine Aluminum Hexagonal Bars for Lightweight Marine Frame Construction

In the ever-evolving marine industry, choosing the correct material for frame construction is a critical factor influencing performance, durability, and safety. Among these materials.

View Details6061 Marine Aluminum Hollow Bars for Marine Hull Repair Parts

6061 marine aluminum hollow bars are a high-performance, versatile material used extensively in marine hull repair parts. Combining excellent corrosion resistance, good mechanical strength, weldability, and machinability.

View Details6061 Marine Grade Aluminum Solid Bar for Marine Vessel Frame Parts

The 6061 Marine Grade Aluminum Solid Bar is a premium-quality aluminum alloy widely recognized for its exceptional strength, corrosion resistance, and versatility.

View Details6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications: Unveiling the Technical Backbone of Modern Maritime EngineeringIn the demanding world of marine engineering.

View Details6061 Marine Aluminum Hexagonal Bars for Boat Hull and Frame Assembly

6061 Marine Aluminum Hexagonal Bars are engineered to deliver exceptional strength, corrosion resistance, and machinability for marine applications. Used widely in boat hull and frame assembly.

View Details

Leave a Message