6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount. Among the myriad options, 6061 marine aluminum rod and bar is know as engineering marvels, offering a blend of strength, corrosion resistance, and versatility.

The Engineering Backbone: What Makes 6061 Marine Aluminum Unique?

6061 aluminum alloy is an aluminum-magnesium-silicon alloy, famed in industrial circles for its excellent mechanical properties and manageable workability. When further processed into marine-grade rods and bars, this alloy emerges optimized to confront one of nature's toughest tests: the maritime environment.

The rod and bar forms deliver material in round or flat cross-sections, ready for machining, extrusion, or fabrication into critical decking components such as support frames, stringers, and fastening elements. Unlike sheet aluminum, which is often prone to surface-level wear, rods and bars possess a denser microstructure allowing them to endure heavy loading and repeated mechanical stresses observed in boat decks.

Corrosion Resistance: Aluminum That Defies Saltwater’s Wrath

The marine environment is synonymous with saltwater exposure, a notorious catalyst for metal degradation through galvanic and pitting corrosion. The real question is—how does 6061 marine aluminum rod/bar repel time and tide?

The answer lies in the tightly adherent alumina (Al2O3) passive oxide film that spontaneously forms on its surface. This layer serves as a self-healing shield that inhibits corrosion propagation, even if superficially scratched. In a boat deck scenario, where water pooling, salt spray, and mechanical abrasion are routine, this self-replenishing barrier maintains structural integrity without the need for heavy coatings or seals.

Weight and Strength: Optimizing Marine Efficiency

Weight is a precious commodity on any sea-faring vessel. Excess structural mass directly compromises fuel efficiency, maneuverability, and payload capacity. This is where 6061 aluminum rod and bar take a comparative image over traditional boat-building metals like steel or even copper alloys.

Although significantly lighter (about one-third the density of steel), 6061 offers yield strength (typically around 240 MPa and tensile strength near 290 MPa in T6 temper). For boat deck designers, this means being able to reduce referenced cross-sections and made assemblies leaner without compromising on the abilities to support load stresses from passengers, equipment, or impact forces against dock edges.

Thermal Conductivity and Machinability from the Designer’s Desk

Another less discussed yet essential feature for boat deck applications is 6061 alloy's favorable thermal conductivity. A well-conducting deck prevents localized heating during summer direct sunlight exposure, thereby protecting non-metallic deck components (such as composites and wood veneers glued onto structural frames) from premature deterioration or delamination failures.

Fabricators and engineers applaud 6061 aluminum rods and bars thanks to their machinability. Cutting, drilling, or welding creates essential bond points with precision, promoting modular design philosophies where decking modules are pre-assembled and fitted to allow maintenance or modification over the vessel’s lifetime.

Versatile Applications: Not Just Beneath Your Feet

Beyond serving as support beams, you will find 6061 marine aluminum rods shaped into nonlinear brackets, custom fasteners, rails, and edging trims in boat decks. Being able to extrude or machine into pretzel-like curves or wave-shaped cross-section bars imparts the aesthetic and ergonomic factor many boutique yacht builders seek today.

By incorporating corrosion-resistant precision, strength-weight advantages, and fabrication compatibility, boat manufacturing can elevate from mere metalwork to a dynamic art form that actually lengthens boat life and reduces ownership hassles.

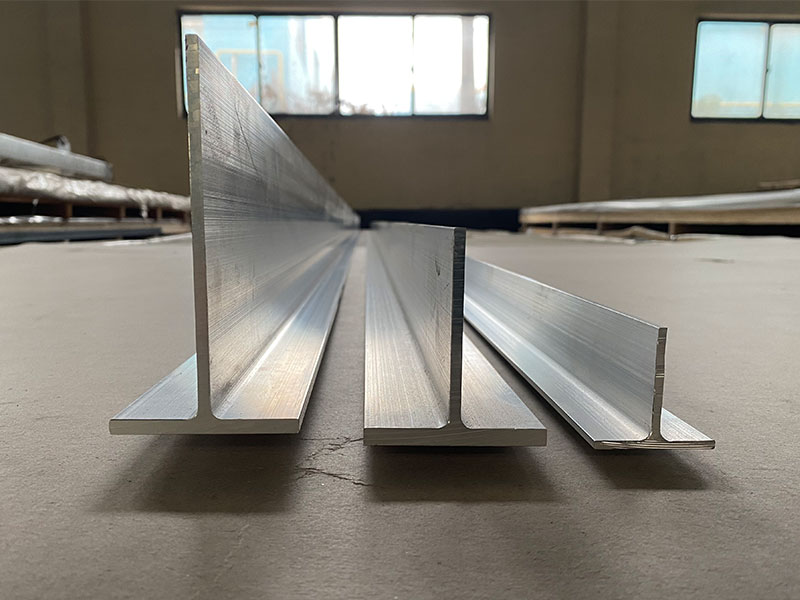

Related Products

Marine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details6061 Marine Aluminum Channels for Custom Marine Component Fabrication

When it comes to constructing reliable, corrosion-resistant, and durable marine structures, the choice of material is pivotal. Among several options.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details

Leave a Message