6061 Marine Aluminum Channels for Custom Marine Component Fabrication

When it comes to constructing reliable, corrosion-resistant, and durable marine structures, the choice of material is pivotal. Among several options, 6061 Marine Aluminum Channels have emerged as a leading solution in custom marine component fabrication due to their unique combination of mechanical strength, excellent corrosion resistance, versatility, and fabricability.

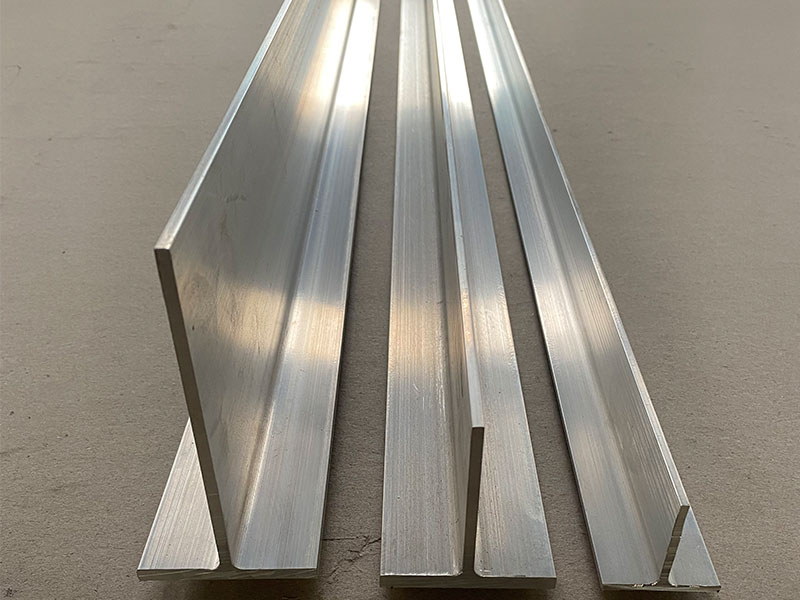

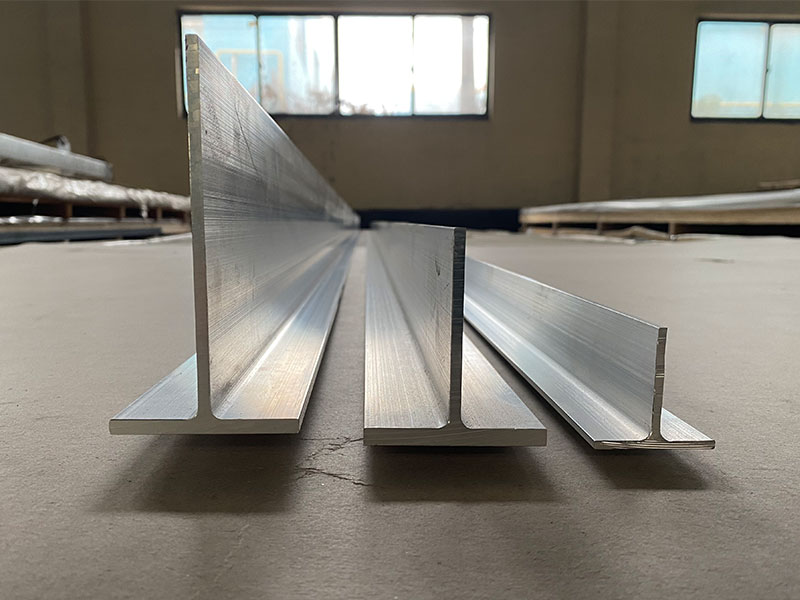

6061 Marine Aluminum Channels

6061 aluminum alloy belongs to the 6xxx series, an alloy system characterized primarily by magnesium and silicon as their main alloying elements. The marine-grade 6061 alloy is crafted specifically with enhanced corrosion resistance to withstand aggressive seawater environments, making it ideal for structural framing, railings, supports, and reinforcements aboard watercraft, docks, and offshore platforms.

- Why Channels?Channels are structural profiles typically featuring a ‘C’ shape cross-section. Their high moment of inertia with minimized weight offers superior strength-to-weight ratios — crucial for weight-sensitive marine designs.

Characteristics & Functions in Marine Use

- Corrosion resistance: Primary for maritime longevity, 6061 aluminum’s stable oxide layer guards against seawater’s corrosive elements, outperforming many steel alloys.

- Lightweight yet robust: Channels crafted from 6061 marine aluminum reduce overall marine vessel weight, significantly improving fuel efficiency and maneuverability.

- Good weldability and machinability: Essential for custom setups, allowing seamless integration into complex marine assemblies with TIG and MIG welding without requiring preheating.

- Fabrication Versatility: Custom drill points, end shapes, and welding preparations can be tailored in fabricating bespoke marine clip-ons, brackets, and supports.

Chemical Properties

| Element | Percentage (%) |

|---|---|

| Silicon (Si) | 0.4 - 0.8 |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.15 - 0.4 |

| Manganese (Mn) | 0.15 max |

| Magnesium (Mg) | 0.8 - 1.2 |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

| Aluminum (Al) | Remainder |

This balanced composition ensures optimal mechanical strength without sacrificing corrosion resistance.

Mechanical and Physical Parameters

- Tensile Strength: Approximately 290 MPa (in T6 temper).

- Yield Strength: About 240 MPa.

- Elongation: Around 12 – 17% depending on temper.

- Density: Approximately 2.70 g/cm³ — making it vastly lighter than steel.

- Thermal Conductivity: ~166 W/m-K; significantly aids heat dissipation in engine and hull structures.

- Electrochemical Potential: Naturally forms a stable passive layer to combat galvanic corrosion.

Standards & Alloy Tempering

Industry Standards:Manufacturing and quality of 6061 marine aluminum channels comply typically with standards like ASTM B221 for extruded aluminum profiles and AMS-QQ-A-200/8 for aluminum alloys’ tight tolerances and compositions.

Common Alloy Tempers for Fabrication:

T4 (Solution Heat-Treated and Naturally Aged): Used where moderate strength with excellent weldability is required.

T6 (Solution Heat-Treated and Artificially Aged): The most used temper offering peak strength, optimal for high-load marine components.

T651 (Stress-Relieved T6): Enhanced residual stress mitigation for complex structural elements.

Tailoring temper depends on specific component strength requirements, welding schedules, and anticipated marine loads.

Implementation in Custom Marine Component Fabrication

In real-world fabrication scenarios, these aluminum channels facilitate:

- Structural Framework: Serving as integral carriers for decks, bulkheads, seating frames immune to weight and corrosion limitations.

- Attachment Profiles: Base rails for external panels or internal cabinetry benefiting from non-corrosive fixings.

- Hydrodynamic Fittings: Channel sections tailored into handling rails or stabilizer reinforcements, blending lightweight and durability.

- Repair & Retrofit Opportunities: Aluminium’s weldability permits spot repairs on exotic shapes or aging components without props for extended dry docking.

- Wire Management & Conduit Support: Channels routed below floors or behind partitions neatly secure wiring and piping, minimizing clutter in marine vessels.

Related Products

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details

Leave a Message