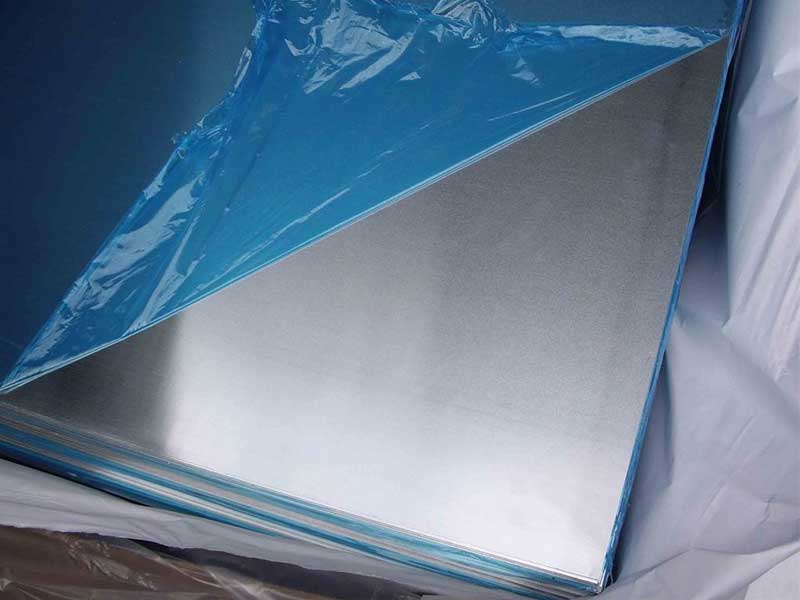

5083 H116 marine grade aluminum alloy sheet plate

5083 H116 marine grade aluminum alloy sheet plate is recognized globally for its exceptional performance in marine environments. As a prominent member of the 5xxx series aluminum alloys, 5083 is an aluminum-magnesium alloy known for excellent corrosion resistance, especially to seawater and marine atmospheres. This makes it an industry favorite for shipbuilding, ship structures, offshore platforms, and other marine applications requiring prolonged exposure to harsh saltwater environments.

Chemical Composition

The characteristic properties of 5083 H116 alloy stem from its chemical makeup, carefully controlled to optimize strength, corrosion resistance, and weldability:

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | Balance (approx. 94.2 - 96.5) |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Chromium (Cr) | 0.05 – 0.25 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Others | ≤ 0.15 combined |

Note: Strict control on impurities such as iron and copper enhances corrosion resistance.

Temper Designation: H116

The temper treatment “H116” is a strain-hardened state with natural aging, with the critical characteristic of having not been annealed after strain hardening. The H116 temper was specially developed for marine grades to offer the best balance between mechanical properties and corrosion resistance — especially stress corrosion cracking (SCC) resistance — when in marine atmospheric and saltwater conditions.

Typically, the strip or sheet in this temper is flat-rolled and strain-hardened to a medium level of strength, overcoming the hinge-like toughness reduction in sub-tempers.

Mechanical Properties

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength (Rm) | 275 – 350 MPa | ASTM B209 / EN 485 |

| Yield Strength (0.2%) | ≥ 215 MPa | |

| Elongation (%) | 12 – 18 % | |

| Hardness (Brinell) | 70 – 90 HB | |

| Density | 2.66 g/cm³ | |

| Modulus of Elasticity | 70 GPa |

Features and Benefits

- Outstanding Corrosion Resistance: Excellent resistance to seawater and saline aerosols withstands marine and offshore environment attacks.

- Enhanced Weldability: Fully weldable by common methods (TIG, MIG, arc welding) with minimal loss of strength.

- Good Formability & Workability: Easy to cold work into complex shapes required in marine structures.

- Lightweight: Offers a high strength-to-weight ratio, optimizing lightweight ship and vessel construction.

- Stress Corrosion Resistance: The unique temper H116 protects against premature cracking from prolonged exposure to salt.

Applications in Marine Industry

- Ship hull structures and decks

- Offshore drilling rigs and platforms

- Marine tanks and bulkheads

- Boat building and yacht construction

- Cryogenic tanks and LNG applications (sometimes aftermarket coatings considered)

- Floating bridges and barges

Implementation Standards & Specifications

5083 H116 aluminum sheets comply fully with the following relevant standards, ensuring uniform quality and performance:

- ASTM B209: Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ISO 6361 (93 H116 Subcategory): Aluminum and aluminum alloys - Sheet, strip, and plate

- AA Alloy Standards: Aluminum Association 5083 grade controls

- EN 485-2: Aluminium and aluminium alloys – Sheet, strip, and plate – Mechanical properties

Fabrication Guidelines

- Cutting: Can be cut by shearing, chips knives, or abrasive methods while minimizing work hardening.

- Welding: Best performed with gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW). Use low iron filler alloys (e.g., 5183) for minimal corrosion risk.

- Bending/Forming: Operate above a suitable min radius (≥2x thickness) for springback control.

- Surface Treatment: Although naturally corrosion resistant, anodizing improves salt-fog resistance and surface finish.

Related Products

Marine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsRelated Blog

Marine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View Details3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments.

View Details5083 marine grade aluminium plate

When it comes to marine construction and applications necessitating optimal performance in corrosive saltwater environments, 5083 marine grade aluminium plate stands out as one of the most reliable and versatile materials.

View DetailsAluminum Alloy Plate 5083 H24 for Marine

OverviewAluminum Alloy Plate 5083 H24 is a high-performance material widely favored in marine engineering due to its excellent combination of high strength, exceptional corrosion resistance, and good weldability.

View DetailsAluminum Sheet Plate alloy 5083 H111 for boat application

When it comes to manufacturing high-performance boats that demand strength, corrosion resistance, and long-lasting durability, Aluminum Sheet Plate Alloy 5083 H111 stands out as a superior material.

View Details

Leave a Message