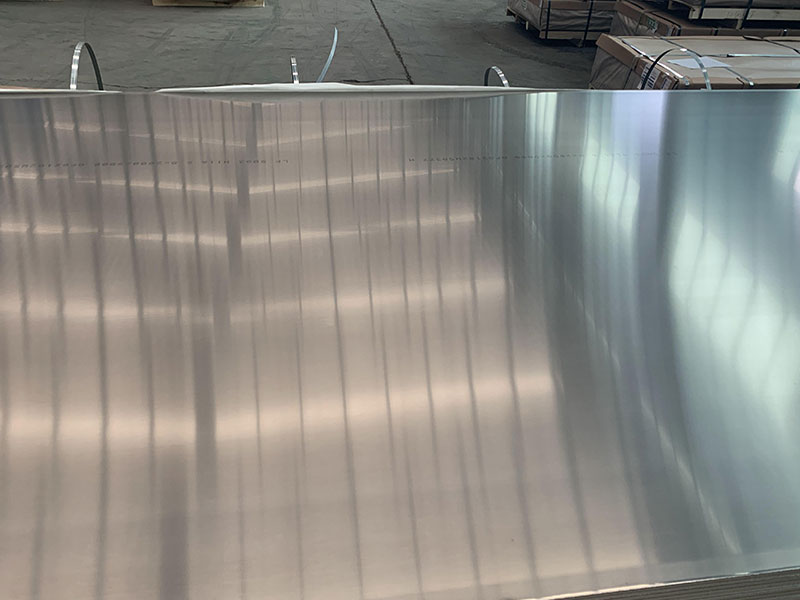

Aluminum foil 0.5mm Thick 5000 Series Marine Grade

Aluminum Foil 0.5mm Thick 5000 Series Marine Grade: A "Sealing Skin" for Real-World Marine Work

When people hear "aluminum foil," they often imagine thin kitchen wrap. In marine manufacturing, however, 0.5mm thick 5000 series marine-grade aluminum foil behaves less like household foil and more like a precision metal membrane-a material that can be bent, formed, sealed, laminated, and fastened while still resisting saltwater corrosion. It's a smart choice when designers need a combination of light weight, barrier performance, and marine durability-especially in spaces where thicker plate would be overkill, and plastics would age, creep, or delaminate.

A distinctive way to understand 0.5mm marine foil is to see it as a functional "skin layer." It's thick enough to hold shape, take fastening and forming loads, and remain stable in temperature swings, yet thin enough to conform to complex surfaces. This gives it a unique position between sheet metal and flexible barrier materials.

What "0.5mm" Really Means in Marine Applications

At 0.5mm, the foil becomes a practical engineering thickness:

- It can be formed into channels, wraps, and protective claddings without cracking when the correct temper is chosen.

- It provides a robust moisture and vapor barrier compared with thinner foils used only for packaging.

- It can be spot welded, riveted, bonded, or mechanically clamped, depending on the project.

- It is ideal as an outer layer over insulation or cores, where it provides abrasion resistance and corrosion tolerance.

In marine environments, thickness also affects service life. A 0.5mm layer offers more "corrosion allowance" than very thin foils, and it is less prone to pinholes or damage during installation.

Why 5000 Series Is the Marine-Grade Workhorse

5000 series aluminum (Al-Mg alloys) is widely recognized as marine grade because magnesium improves both strength and corrosion resistance, particularly in chloride-rich environments. Unlike heat-treatable alloys, 5000 series gains strength primarily through work hardening, which helps maintain predictable performance during forming.

Common marine-grade 5000 series choices for 0.5mm foil/sheet applications include:

- 5052: Excellent formability, strong general corrosion resistance, widely used for marine fittings, cladding, and fabricated parts.

- 5083: Higher strength, strong seawater resistance, commonly used in hull structures; forming at thin gauges depends more on temper and bend radius control.

- 5754: Balanced corrosion resistance and formability, often used for panels and general marine fabrications.

If your application involves complex forming and tight bends, 5052 or 5754 often feels "friendlier." If you need higher mechanical performance and stiffness at the same thickness, 5083 may be preferred-while paying closer attention to temper selection and fabrication practices.

Temper Selection: Controlling Springback, Formability, and Stability

Because 5000 series is non-heat-treatable, temper becomes the practical dial that controls performance.

Common tempers for 0.5mm marine foil include:

- O (Annealed): Maximum ductility and formability; best for deep forming, wrapping, and tight-radius bends. Lower strength, but excellent for complex shapes.

- H22 / H24: Strain-hardened (and partially annealed for H24). Good balance of strength and formability; widely used for cladding, covers, and formed components.

- H32 / H34: Higher strength with reduced formability; suitable where stiffness and dent resistance matter more than tight bends.

A practical viewpoint is to choose temper by asking: is the foil meant to conform, span, or shield? Conforming favors O or H24; spanning and shielding often favor H32/H34.

Functions: More Than Corrosion Resistance

Marine-grade 0.5mm 5000 series foil performs several jobs at once:

Corrosion defense in salt air and splash zones

Al-Mg alloys naturally form a protective oxide film. When paired with appropriate coatings or isolation from dissimilar metals, they perform reliably in marine atmospheres.

Barrier and sealing performance

At 0.5mm, the material is a stable barrier layer for moisture, fumes, and contamination-useful in insulation jacketing, tank surrounds, or enclosed compartments.

Weight-efficient stiffness

Even at 0.5mm, aluminum offers a meaningful stiffness-to-weight advantage compared with many stainless solutions used as cladding.

Thermal conductivity and heat spreading

It helps equalize temperatures and dissipate heat, which is helpful in equipment housings, battery enclosures, and thermal shielding assemblies.

Typical Marine and Coastal Applications

Because it behaves like a "metal skin," this product shows up in places customers don't always notice:

- Insulation jacketing for marine piping, exhaust trunks, or HVAC sections where salt air demands corrosion resistance

- Protective cladding over foam or composite cores in lightweight marine panels

- Compartment liners and covers in engine rooms or storage bays

- Splash-zone shields and sacrificial wrap layers that take abrasion and can be replaced without rebuilding the base structure

- Fabricated ducts, casings, and brackets where thin-gauge corrosion resistance is required

- Reflective thermal barriers when paired with surface finishing or laminated constructions

Parameters (Typical Supply Range)

The following are common supply parameters for 0.5mm 5000 series marine-grade aluminum foil/sheet:

- Thickness: 0.50 mm (tolerance per standard and supplier capability)

- Width: commonly 100–1600 mm (custom slitting available)

- Length: coils or cut-to-length sheets depending on requirement

- Surface finish: mill finish, one-side film, brushed, or coated (project-driven)

- Alloys available: 5052, 5083, 5754

- Tempers available: O, H22, H24, H32, H34 (availability varies by alloy and mill)

For applications involving bonding, sealing, or coating, it is worth specifying surface cleanliness requirements and whether film protection is needed to prevent handling marks.

Implementation Standards and Common References

Marine and industrial buyers frequently align procurement and inspection to one or more of the following standards (equivalents may be acceptable depending on region and project):

- ASTM B209 / ASTM B209M: Aluminum and Aluminum-Alloy Sheet and Plate (widely used for 5000 series sheet)

- EN 485 (parts applicable): European requirements for tolerances and mechanical properties of wrought aluminum sheet/strip

- ISO 6361 (where applicable): Wrought aluminum sheets/strips-technical conditions

When the foil is used as part of a marine system, additional project specs may apply for coating systems, insulation jacketing practices, or galvanic isolation requirements.

Chemical Composition (Typical, % by Weight)

Values below are typical specification ranges; always confirm with mill test certificates for your exact alloy.

| Alloy | Mg | Mn | Cr | Si | Fe | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | 2.2–2.8 | ≤0.10 | 0.15–0.35 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | ≤0.15 | Balance |

| 5083 | 4.0–4.9 | 0.4–1.0 | 0.05–0.25 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.25 | ≤0.15 | Balance |

| 5754 | 2.6–3.6 | ≤0.50 | ≤0.30 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.20 | ≤0.15 | Balance |

A distinctive takeaway is that magnesium is the marine "insurance element." More Mg generally increases strength and marine corrosion resistance, while also making fabrication choices like temper and bend radius more important.

Practical Notes for Successful Use

To get the best real-world performance from 0.5mm marine-grade foil, the details of installation matter as much as alloy choice:

Avoid galvanic traps by isolating aluminum from copper-rich alloys and certain stainless assemblies when moisture is present. Use barrier tapes, coatings, or compatible fasteners. For forming, match bend radii to temper and consider annealed tempers for tight work. If welding is required, confirm alloy and filler compatibility and avoid overheating thin gauge.

Aluminum foil 0.5mm thick in 5000 series marine grade is not just "thin metal." It's a quiet enabler for marine design-lightweight, corrosion-resistant, formable, and stable enough to serve as a protective outer skin, a barrier layer, or a fabricated component. When specified with the right alloy-temper pairing and backed by recognized standards, it becomes a dependable building block for coastal and marine products that need longevity without unnecessary mass.

Related Products

Marine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsRelated Blog

6061 5mm thick 4x8 aluminum sheet for boat

When it comes to maritime applications, selecting the right materials is crucial. Among the varied options available in the world of marine engineering, the 6061 aluminum alloy stands out especially for its versatility, durability, and performance.

View Details3mm Thickness 8x4 Aluminum Sheet 5083 For Boat

Marine builders choose materials that survive salt spray, wave impact, and years of cyclic loading without becoming a maintenance burden. 3mm thickness 8x4 aluminum sheet 5083 is a proven marine-grade plate/sheet option used worldwide for boat hulls.

View DetailsAluminum sheet for boat 5083 5052 5754

When selecting aluminum sheets for marine applications, particularly boats, alloy choice plays a vital role in ensuring durability, corrosion resistance, and mechanical strength.

View DetailsMill Finish Aluminium Sheet for Ship building

When it comes to shipbuilding, choosing the right materials is pivotal for ensuring both durability and optimal performance. Among various options, mill finish aluminium sheet stands out as a superior choice.

View DetailsMarin grade aluminum sheet 5052 5mm thick for boat

What is Marine Grade Aluminum 5052?Aluminum 5052 is a non-heat-treatable aluminum-magnesium alloy primarily known for excellent corrosion resistance, high strength among the non-heat treatable grades, and superb weldability.

View DetailsAluminum Sheet 5083 5086 5754 for Fishing Boat

Aluminum sheets 5083, 5086, and 5754 are widely recognized alloys in the marine industry, known for their excellent corrosion resistance, mechanical strength, and durability.

View Details

Leave a Message