Marine grade aluminum sheet 5083 for ship building

Marine environments punish materials with salt spray, humidity, cyclic loads, and constant maintenance pressure. 5083 marine grade aluminum sheet is widely selected for shipbuilding because it delivers an excellent balance of seawater corrosion resistance, weldability, and high strength without heat treatment, making it a practical "workhorse" alloy for hull structures and superstructures.

5083 is an Al–Mg–Mn alloy (5xxx series). Its strength is primarily achieved through solid-solution strengthening from magnesium and strain hardening (temper-dependent), not precipitation hardening. This gives it reliable performance in welded structures and stable properties over time in service.

Why 5083 Is a Marine-Grade Standard

Features at a Glance

| Feature | What it Means in Shipbuilding | Customer Value |

|---|---|---|

| Excellent seawater corrosion resistance | Resists pitting/crevice corrosion and general attack in marine atmospheres | Longer service life, lower repainting/repair costs |

| High strength-to-weight ratio | Stronger than many common marine alloys at similar thickness | Lighter vessels, improved payload and fuel economy |

| Outstanding weldability | Common marine welding processes work well (GMAW/MIG, GTAW/TIG) | Faster fabrication, fewer defects, robust joints |

| No heat treatment required | Properties achieved by temper and forming | Simplified production and predictable behavior |

| Good toughness at low temperature | Maintains toughness compared with some alternatives | Suitable for colder routes and offshore conditions |

Typical Applications in Shipbuilding

5083 sheet and plate are chosen when designers need structural integrity plus corrosion performance.

| Vessel/Structure Area | Typical Components | Why 5083 Fits |

|---|---|---|

| Hull and side shell | Hull plating, strakes, collision bulkheads | High strength, strong corrosion resistance in seawater |

| Deck structures | Weather decks, deckhouses, hatch covers | Reduced topside weight, good weldability |

| Superstructure | Bridge structures, accommodation modules | Weight reduction improves stability and speed |

| Internal structures | Bulkheads, stiffeners (with appropriate product forms) | Durable welded construction |

| Offshore and marine equipment | Gangways, platforms, boat davits | Corrosion resistance + stiffness at lower mass |

Chemical Composition (Typical/Standard Ranges)

5083's performance is driven by its magnesium content and controlled additions of manganese and chromium, which improve strength and corrosion behavior. The composition below reflects common industry specifications (exact limits vary by standard and supplier certification).

| Element | Typical Range (wt.%) | Role in the Alloy |

|---|---|---|

| Mg | 4.0 – 4.9 | Primary strength contributor; improves strain hardening |

| Mn | 0.4 – 1.0 | Increases strength; helps with grain structure control |

| Cr | 0.05 – 0.25 | Improves corrosion resistance and toughness |

| Si | ≤ 0.40 | Impurity/controlled; excess can reduce ductility |

| Fe | ≤ 0.40 | Impurity/controlled; excess can affect toughness |

| Cu | ≤ 0.10 | Kept low to protect corrosion resistance |

| Zn | ≤ 0.25 | Controlled for corrosion and weld behavior |

| Ti | ≤ 0.15 | Grain refinement in processing |

| Al | Balance | Base metal |

Mechanical Performance (By Temper)

Marine shipbuilding commonly uses 5083-H116 and 5083-H321 because they are optimized for marine service and offer good resistance to exfoliation and stress corrosion in typical operating ranges. Values below are representative; always confirm with the mill test certificate for your thickness.

| Property | 5083-H116 (Typical) | 5083-H321 (Typical) | Why It Matters |

|---|---|---|---|

| Tensile strength (MPa) | 305 – 360 | 305 – 360 | Overall load capacity of plating |

| Yield strength (MPa) | 215 – 260 | 215 – 260 | Design allowable stress and stiffness |

| Elongation (%) | 10 – 16 | 10 – 16 | Formability and tolerance to local strain |

| Hardness (HB, approx.) | 80 – 95 | 80 – 95 | Wear and dent resistance (indicative) |

| Density (g/cm³) | 2.66 | 2.66 | Weight estimation and buoyancy calculations |

Practical note: For welded ship structures, joint efficiency, weld procedure qualification, and heat input control often matter as much as base-metal strength. 5083 generally retains strong, reliable properties in properly executed welds.

Corrosion Resistance in Marine Service

5083 is widely referred to as "marine grade" because it performs well in:

- Seawater splash zones

- Marine atmospheres (salt-laden air)

- Bilge and compartment environments (with good drainage and coating practice)

Corrosion Performance Considerations

| Condition | 5083 Behavior | Recommended Practice |

|---|---|---|

| Seawater exposure | Strong resistance to general corrosion | Use marine coating systems where required by class/owner |

| Crevice areas (laps, tight gaps) | Crevice corrosion risk exists in all aluminum alloys | Design to avoid stagnant crevices; seal and drain |

| Galvanic coupling (with steel/copper alloys) | Aluminum can corrode rapidly when coupled | Isolate with gaskets, coatings, and proper fasteners |

| Elevated temperature service | High Mg alloys can be sensitized at certain ranges | Avoid prolonged exposure in critical temperature windows; follow spec guidance |

Technical Specifications (Sheet Supply)

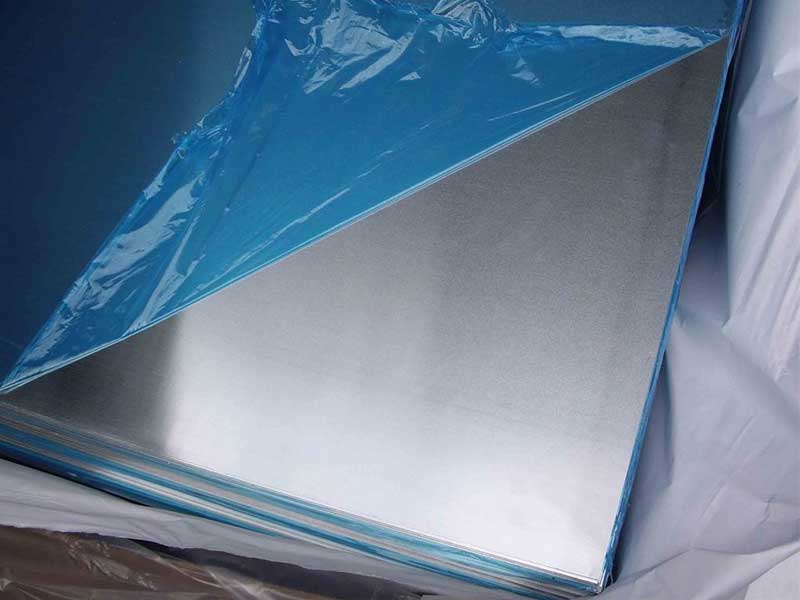

5083 can be supplied as sheet or plate depending on thickness. For shipbuilding, customers typically specify standards and tempers suitable for marine classification and service.

| Parameter | Typical Options | Notes |

|---|---|---|

| Product form | Sheet / Plate | Plate is used for heavier hull structures; sheet for lighter fabrications |

| Thickness range | ~1.5 mm up to 50+ mm (product-dependent) | Availability varies by mill and width requirements |

| Width | Commonly 1000–2500 mm | Wider plates available for hull efficiency |

| Length | Cut-to-length or coil (thin gauges) | Plate often supplied leveled cut lengths |

| Tempers | H116, H321, H111, O (annealed) | H116/H321 common for marine structural use |

| Surface finish | Mill finish, brushed, coated (by request) | Finish selection affects appearance and coating adhesion |

| Standards (typical) | ASTM B928 / ASTM B209, EN 485 / EN 573 | Confirm class/yard specification alignment |

Fabrication: Forming, Welding, and Machining

Forming

5083 offers good formability, especially in softer tempers. For tight radii or complex shapes, selecting the appropriate temper (or localized forming strategy) can reduce cracking risk.

| Fabrication Operation | 5083 Behavior | Tip |

|---|---|---|

| Bending | Good, temper-dependent | Use larger inside radii for H116/H321 than O temper |

| Rolling | Good | Control springback; verify flatness requirements |

| Cutting | Good (shear, saw, waterjet, plasma) | For critical edges, finish to remove notches |

Welding

5083 is well-suited for marine welding. Common filler alloys include ER5356 (often chosen for strength and marine service). Proper weld procedures help preserve corrosion resistance and minimize distortion.

| Welding Aspect | Typical Practice | Why It Helps |

|---|---|---|

| Process | MIG/GMAW, TIG/GTAW | Proven, repeatable marine fabrication methods |

| Filler | 5xxx fillers (e.g., 5356) | Compatible chemistry and good joint strength |

| Heat input | Controlled | Reduces distortion and preserves properties |

| Post-weld | Cleaning, passivation practices | Removes contaminants; improves coating adhesion |

Benefits for Customers: What You Get in Real Projects

| Benefit | Project Impact | Typical Outcome |

|---|---|---|

| Weight reduction vs. steel | Lower displacement and fuel consumption | Better speed/payload and easier handling |

| Lower maintenance in marine atmosphere | Less repainting and corrosion repair | Lower lifecycle cost |

| High structural reliability | Stable properties in welded assemblies | Fewer failures and longer inspection intervals |

| Design flexibility | Works across hull, deck, and superstructure | Simplified material sourcing and inventory |

Common Use-Case Scenarios

- Fast patrol craft and workboats: 5083 enables high strength with reduced hull weight, supporting speed and payload.

- Ferries and passenger vessels: Lighter superstructures improve stability and reduce fuel use without sacrificing corrosion performance.

- Fishing vessels: Durable plating and good weldability make repairs and modifications practical over long service lives.

- Offshore support structures: Strong corrosion resistance plus weld-friendly fabrication supports rugged operating profiles.

How to Specify 5083 Sheet for Shipbuilding (Buyer Checklist)

| Item to Confirm | What to Request | Why It Matters |

|---|---|---|

| Temper | H116 or H321 (typical marine choice) | Better marine service reliability |

| Standard | ASTM/EN requirement matching your project | Ensures compliance and traceability |

| Thickness & tolerances | Nominal + flatness requirement | Affects fit-up, distortion, and fairness |

| Certification | Mill Test Certificate (MTC) | Verifies chemistry and mechanical properties |

| Surface condition | Mill finish / protective film | Prevents handling damage and contamination |

Marine grade aluminum sheet 5083 is a high-performance, ship-proven alloy valued for seawater corrosion resistance, excellent weldability, and strong structural capability. For shipyards and marine fabricators, it offers a practical path to lighter vessels, efficient fabrication, and lower lifecycle maintenance, especially when specified in marine-optimized tempers such as H116 or H321.

Related Products

Marine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsRelated Blog

2mm 3mm 4mm marine grade 5083 aluminum sheet

When considering materials for marine applications, the demand for durability, adaptability, and weight efficiency comes to the forefront of innovation. One leading solution in this arena is the 5083 aluminum alloy.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

View Details5052 5083 5086 Marine Grade Aluminium Sheet for Boat Building

Marine-grade aluminum is essential for constructing durable, lightweight vessels capable of withstanding harsh marine environments. In particular, 5052, 5083.

View Details5083 marine grade anodized aluminum sheets coils

In the marine industry, where durability, corrosion resistance, and lightweight materials are quintessential, 5083 marine grade anodized aluminum sheets and coils stand as a pinnacle product.

View DetailsASTM B209 aluminum sheet 5083 for ship

ASTM B209 Aluminum Sheet 5083 for Shipbuilding: A Functional View from the Waterline Up When ship designers choose materials, they are not just selecting metal; they are choosing how a vessel behaves at sea over decades.

View Details3mm Thickness 8x4 Aluminum Sheet 5083 For Boat

Marine builders choose materials that survive salt spray, wave impact, and years of cyclic loading without becoming a maintenance burden. 3mm thickness 8x4 aluminum sheet 5083 is a proven marine-grade plate/sheet option used worldwide for boat hulls.

View Details

Leave a Message