6061 5mm thick 4x8 aluminum sheet for boat

When it comes to maritime applications, selecting the right materials is crucial. Among the varied options available in the world of marine engineering, the 6061 aluminum alloy stands out especially for its versatility, durability, and performance. One of the popular specifications in this category is the 6061 5mm thick 4x8 aluminum sheet.

6061 aluminum is a medium to high-strength alloy made with magnesium and silicon as its major alloying elements. It poses excellent weldability, corrosion resistance, and competitiveness in markets requiring both durability and weight considerations, making it ideal for marine environments.

Features and Functions of 6061 Aluminum

- Lightweight: The low density of aluminum provides ease in crafting frames and hull designs without compromising structural integrity.

- Corrosion Resistant: 6061 ensures longevity, offering enhanced resistance against moist environments prevalent in marine activities.

- Malleability: It can be easily shaped and machined, aiding significantly in various boat components manufacturing.

- Good Mechanical Properties: This aluminum alloy maintains satisfactory strength across a range of environmental conditions, making it formidable for boat-building applications.

- Weldability: It can be readily welded by the most common welding techniques typical in die fabricating.

Applications of 6061 Aluminum Sheets in Marine Engineering

General Applications

- Boat Hulls: Perfect for the hull body due to its highs strength-to-weight ratio

- Deck fittings: Including bulkheads and bridges

- Frames and Fittings: Structural frames, engine mounts, and more

- Sailboat Masts: Employed in creating durable yet lightweight masts for boat sails

Specialized Applications

- Fishing Boats: Ensures thin resources created remain true to form while supporting functionality

- Recreation Vessels: From kayaks to larger leisure craft, adding rigidness while ensuring sportiness

Technical Details of 6061 5mm Thick 4x8 Aluminum Sheets

the chemistry and mechanical properties of 6061 aluminum sheet helps manufacturers and users derive efficient usage modes suited to their needs. Below is detailed information regarding its properties.

Chemical Composition

| Element | Weight Percentage |

|---|---|

| Aluminum (Al) | 97.9% - 98.6% |

| Silicon (Si) | 0.4% - 0.8% |

| Iron (Fe) | 0.7% max |

| Copper (Cu) | 0.15% - 0.40% |

| Manganese (Mn) | 0.15% max |

| Magnesium (Mg) | 0.8% - 1.2% |

| Chromium (Cr) | 0.04% - 0.35% |

| Zinc (Zn) | 0.25% max |

| Titanium (Ti) | 0.15% max |

Technical Specifications

| Attribute | Value |

|---|---|

| Thickness | 5 mm |

| Sheet Size | 4 ft x 8 ft (1220 x 2440 mm) |

| Alloy | 6061 |

| Tempering Condition | T6512 (Solution Heat Treated and artificially aged) |

| Density | ~2.70 g/cm³ |

| Tensile Strength (MPa) | 275 - 310 |

| Yield Strength (MPa) | 240 - 270 |

| Electrical Conductivity (% IACS) | 32% |

Mechanical Properties

- Elongation at break: Approx. 12-16% (in original length)

- Fatigue Strength: Extruded 6061 has good fatigue properties useful in marine applications

Implementation Standards

The aluminum sheets conform to various industry standards including:

- ASTM B221: Specification for Aluminum and Aluminum-alloy Extruded Bars, Rods, Wires, Profiles, and Tubes.

- ASTM B209: Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

Related Products

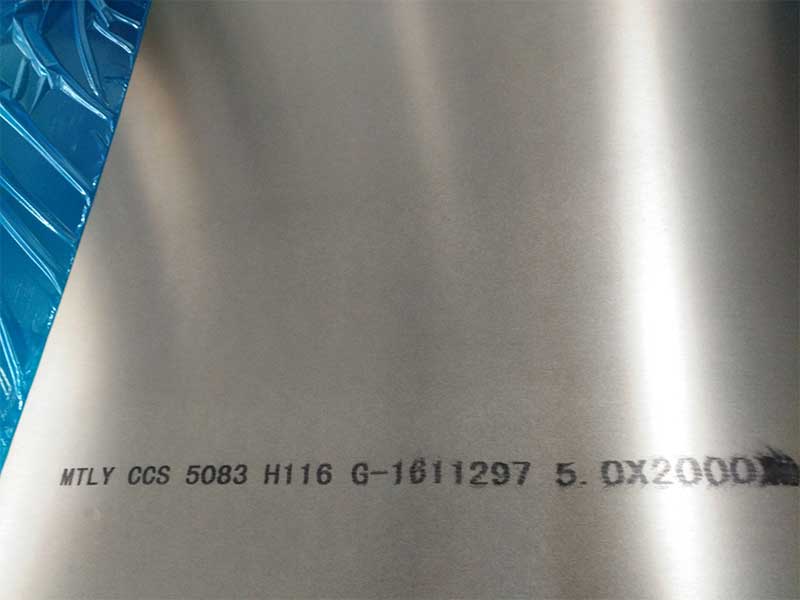

Marine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsRelated Blog

6061 5mm thick 4x8 aluminum sheet for boat

When it comes to maritime applications, selecting the right materials is crucial. Among the varied options available in the world of marine engineering, the 6061 aluminum alloy stands out especially for its versatility, durability, and performance.

View DetailsAluminum sheet tai 6061 alloy metal rolls for boat

Aluminum has long been the favored material in maritime applications due to its unique combination of lightweight characteristics and exceptional resistance to corrosion.

View Details

Leave a Message