6082 Marine Aluminum Square Tubes for Saltwater Resistant Applications

When marine structures meet saltwater, materials face a relentless mix of chloride attack, wet–dry cycling, abrasion, and galvanic exposure to dissimilar metals. 6082 Marine aluminum square tubes are a practical, high-strength choice for these conditions, combining excellent corrosion resistance, robust mechanical performance, and good fabrication characteristics. The square-tube geometry also delivers efficient load distribution, clean aesthetics, and easy integration into modular marine frames.

6082 (Al-Mg-Si) is widely used across marine and coastal industries because it balances strength and corrosion performance without the weight penalty of steel or the cost of specialized exotic alloys. In saltwater resistant applications, 6082 square tubes are commonly specified in T6/T651 tempers, offering dependable strength for structural members while remaining weldable and machineable for custom builds.

Why 6082 Square Tubes Perform in Marine Environments

Saltwater resistance in aluminum is mainly governed by alloy family, microstructure, and surface condition. 6082's magnesium and silicon form the Mg₂Si strengthening phase, producing a strong yet corrosion-resistant matrix. Compared to many general-purpose alloys, 6082 provides:

- High strength-to-weight ratio for load-bearing marine frames and supports

- Strong resistance to atmospheric and splash-zone corrosion when properly finished

- Good weldability for common marine fabrication processes

- Excellent extrudability, enabling tight dimensional control and consistent tube quality

- Square geometry advantages for bracing, fastening, and clean assembly alignment

While 5xxx alloys are famous for marine sheet and plate, 6082 is a standout for extruded structural profiles, especially tubes, where stiffness and straightness matter.

Chemical Composition (Typical, EN AW-6082)

The chemistry of 6082 is designed for strength, extrusion performance, and corrosion resistance. Values below represent common specification limits; exact ranges may vary slightly by standard and supplier control plan.

| Element | Typical Specification Range (wt.%) | Role in Performance |

|---|---|---|

| Si | 0.70–1.30 | Strengthening via Mg₂Si; improves extrudability |

| Mg | 0.60–1.20 | Corrosion resistance; strength contribution |

| Mn | 0.40–1.00 | Grain structure control; toughness and strength stability |

| Fe | ≤ 0.50 | Impurity control; excess may reduce toughness/corrosion performance |

| Cu | ≤ 0.10 | Limited to protect corrosion resistance |

| Cr | ≤ 0.25 | Structure control (minor); may aid property consistency |

| Zn | ≤ 0.20 | Controlled impurity |

| Ti | ≤ 0.10 | Grain refinement in casting/extrusion billet |

| Al | Balance | Base metal |

Mechanical Properties (Typical Values)

6082 square tubes for marine structural use are commonly supplied in T6 (solution heat-treated and artificially aged) or T651 (T6 with stress-relief stretching). T651 can be preferred when dimensional stability during machining is critical.

| Property | 6082-T6 Typical | Notes |

|---|---|---|

| 0.2% Proof Strength (MPa) | 240–280 | Depends on thickness and process |

| Ultimate Tensile Strength (MPa) | 290–340 | Strong for an extruded marine alloy |

| Elongation (%) | 8–12 | Sufficient ductility for structural service |

| Brinell Hardness (HBW) | 90–110 | Useful indicator for wear/handling resistance |

| Density (g/cm³) | 2.70 | Lightweight versus steel |

| Elastic Modulus (GPa) | ~69 | Design stiffness parameter |

| Thermal Conductivity (W/m·K) | ~170–200 | Varies with temper and exact chemistry |

Technical Specifications for Marine Square Tubes

6082 square tubes are extruded and can be supplied in a wide range of sizes. For marine customers, the is matching wall thickness to stiffness, weld detail requirements, and corrosion allowance-without unnecessary weight.

| Parameter | Common Supply Range | Notes for Marine Projects |

|---|---|---|

| Outside dimension (A × A) | 20 × 20 mm to 200 × 200 mm | Larger sizes available with tooling |

| Wall thickness (t) | 1.5 mm to 12 mm | Thicker walls improve weld tolerance and stiffness |

| Length | 3–7 m typical | Cut-to-length available |

| Temper | T6 / T651 | T651 preferred for machining stability |

| Standards (typical) | EN 755 / ASTM B221 (by agreement) | Confirm compliance and inspection plan |

| Straightness & twist | Controlled per extrusion tolerances | Important for modular frames and long spans |

| Surface | Mill finish / anodized / powder coated | Finish selection drives corrosion performance |

Corrosion Behavior in Saltwater Service

6082 offers strong resistance in marine atmosphere, splash zones, and coastal industrial environments, especially when paired with the right surface protection. Practical corrosion considerations include:

- Pitting resistance is generally good for Al-Mg-Si alloys, but pitting can occur in stagnant saltwater or under deposits.

- Crevice corrosion can develop at tight overlaps, under fasteners, and beneath trapped salt deposits. Joint design and sealing matter as much as alloy selection.

- Galvanic corrosion is a major design driver. Aluminum coupled with stainless steel or copper alloys in seawater can corrode rapidly if not electrically isolated.

| Marine Exposure Factor | Risk Level | Recommended Mitigation |

|---|---|---|

| Splash & spray | Medium | Anodize or marine powder coat; rinse-down maintenance |

| Full immersion | Medium to High | Consider design review; use protective coatings and isolation strategy |

| Crevices and lap joints | High | Sealants, drainage, avoid salt traps |

| Stainless fasteners contact | High | Use isolating washers/sleeves; coat contact areas |

| Copper/brass contact | Very High | Avoid or fully isolate; barrier coatings |

Fabrication and Finishing: What Customers Should Know

6082 square tubes are built for fabrication-friendly workflows, from handrail welding to CNC-machined marine brackets.

Welding

6082 is readily weldable using common processes such as MIG/TIG. Like most heat-treatable alloys, the heat-affected zone experiences strength reduction relative to T6 base metal. Designs that account for weld efficiency, joint geometry, and post-weld finishing deliver excellent real-world performance.

| Fabrication Topic | Practical Guidance |

|---|---|

| Welding filler | ER5356 often used for marine work |

| Post-weld strength | Reduced near weld |

| Machining | Very good in T651 |

| Bending/Forming | Moderate |

| Joining | Bolted or riveted |

Surface protection options

A good finish is a force multiplier in saltwater exposure. Selection depends on abrasion, UV, aesthetics, and maintenance plans.

| Finish | Advantages | Typical Marine Uses |

|---|---|---|

| Mill finish (with maintenance) | Lowest cost | Internal frames, protected compartments |

| Anodizing | Hard, corrosion-resistant oxide layer | Rails, ladders, deck hardware, exposed frames |

| Marine powder coating | Thick barrier; color options | T-tops, consoles, decorative frames |

| Paint systems (primer + topcoat) | Repairable; heavy-duty | Large structures, mixed-metal assemblies |

Applications: Where 6082 Marine Square Tubes Shine

6082 square tubes are chosen when projects need a structural backbone that resists coastal corrosion without becoming difficult to fabricate. Typical applications include:

- Boat structural framing for decks, lockers, and equipment supports

- T-top and canopy structures, where stiffness and clean lines matter

- Marine handrails, ladders, and guard structures with anodized or powder-coated finish

- Dock and marina components, including frames, bracing, and utility mounts

- Aquaculture and coastal infrastructure, such as walkways, supports, and housings

- Offshore and nearshore equipment frames for sensors, enclosures, and maintenance platforms

- Trailer and transport frames used around saltwater ramps and coastal logistics

The square-tube profile is especially valued for easy attachment of panels, straightforward corner joints, and high torsional stability in compact structures.

Selection Tips for Saltwater Resistant Results

Choosing the right tube is more than picking a size-marine longevity comes from matching alloy, temper, design details, and finish.

| Design Choice | Recommendation | Why It Helps |

|---|---|---|

| Temper | T6 for general strength; T651 for machined parts | Strength and dimensional stability |

| Wall thickness | Use adequate thickness at welded joints | Reduces distortion and improves fatigue margin |

| Joint design | Avoid crevices; include drainage paths | Minimizes crevice corrosion |

| Fasteners | Isolate stainless; avoid copper alloys | Prevents galvanic acceleration |

| Finish | Anodize or marine powder coat for exposed use | Reduces pitting risk and improves appearance |

6082 Marine aluminum square tubes offer a compelling mix of strength, saltwater resistance, and fabrication flexibility, making them a dependable choice for coastal and marine structures. With thoughtful joint design, galvanic isolation, and a suitable finish such as anodizing or marine-grade powder coating, 6082 square tubes deliver long service life in harsh chloride environments-while keeping structures lightweight, clean, and easy to build.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

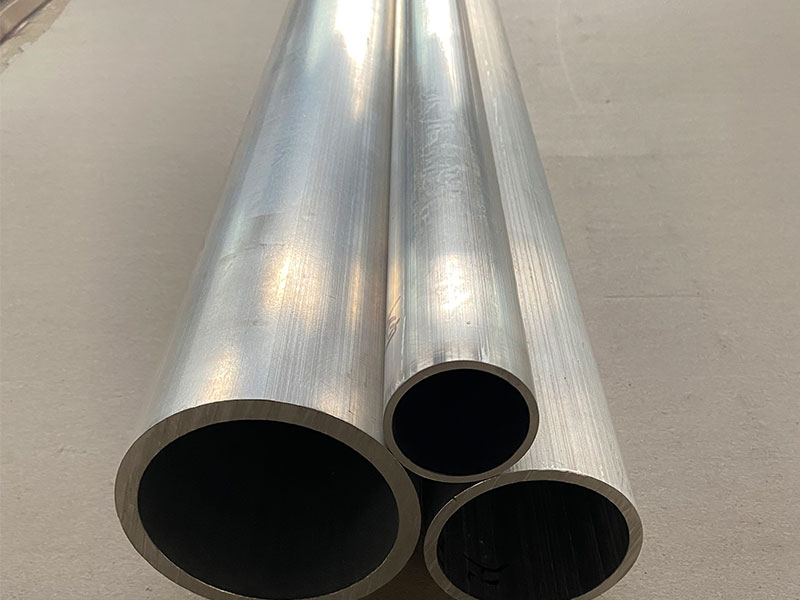

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details6082 Marine Aluminum Tubes for Superyacht Construction

6082 Marine Aluminum Tubes for Superyacht ConstructionA Technical Deep Dive from a Designer’s Perspective In modern superyacht construction, 6082 marine aluminum tubes occupy a quiet but critical role.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details6082 Marine Aluminum Tubes for Coastal Marine Infrastructure

In native natural ecosystems straddling our planet’s coastlines, coastal marine infrastructure serves as the lifeblood of myriad industries, ranging from transportation to tourism, aquaculture, and conservation initiatives.

View Details6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details

Leave a Message