Aluminum Pipe Elbow for Shipboard Refrigeration Lines

In the world of marine refrigeration systems, maintaining integrity, durability, and corrosion resistance is critical to ensure onboard equipment functions on long sea voyages. Among the vital accessories in shipboard refrigeration lines, the Aluminum pipe elbow plays a pivotal role, particularly when fabricated from specialized Marine Aluminum alloys.

Why Aluminum Pipe Elbows for Shipboard Refrigeration?

Ships rely increasingly on aluminum alloys due to their lightweight, anti-corrosive properties, and excellent thermal conductivity. Aluminum pipe elbows are essential components that enable redirection of refrigerant flow with minimal pressure drop and superior corrosion resistance. Unlike conventional steel elbows, marine aluminum makes shipboard refrigeration lines more resilient to seawater environments, and reduces heat loss—a vital factor for preserving low temperatures in refrigeration.

Unique Technical Outlook: Alloy Temper, Implementation and Standards

Alloy Selection and Tempering

The typical aluminum alloys used in marine refrigeration pipe elbows are drawn from the 5xxx series, specifically 5083-H321 or 5454-H32 grades. These offer:

- Superior corrosion resistance, especially against seawater-induced pitting and stress corrosion cracking.

- Adequate strength required for pressure regulation in refrigeration systems.

- Excellent weldability important for onboard fabrication and installation.

Heat Treatment / Temper Conditions:

- H321 Temper: Solution heat-treated and strain-hardened by controlled stretching, offering improved strength with corrosion resistance.

- H32 Temper: Partially annealed, balancing strength and ductility for optimum performance under bending and pressure changes in processing.

Implementation Parameters for Marine Aluminum Pipe Elbows

| Parameter | Specification | Description |

|---|---|---|

| Alloy | 5083-H321, 5454-H32 | Marine-grade aluminum alloy, enhanced corrosion resistance |

| Mechanical Strength | Tensile Strength ≥ 290 MPa | Ensures pressure reliability |

| Elongation | ≥ 12% | Provides ductility avoiding crack formation under cooling cycles |

| Thickness | Typical range: 2 mm to 12 mm | Adapted per application; thicker pipes resist higher pressures |

| Bending Radius | 1.5× to 3× the pipe diameter | Optimized for minimal flow disturbance |

| Surface Finish | Smooth, passivated, and sometimes anodized | Minimizes friction and enhances corrosion resistance |

Implementation and Installation Standards in Shipboard Refrigeration:

- ABS Rules for Building and Classing Steel Vessels – Aluminum adaptations

- ISO 15590-3 – Plastics piping systems for surface and subsea and temperature ranges.

- Custom marine industry benchmarks for weld quality and pressure testing at 1.5 times working pressure.

Chemical Composition of Selected Aluminum Alloys

| Element | 5083 Alloy % | 5454 Alloy % |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium (Mg) | 4.0 - 4.9 | 2.2 - 2.8 |

| Manganese (Mn) | 0.4 - 1.0 | 0.3 - 0.7 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 |

| Chromium (Cr) | 0.05 - 0.25 | 0.05 - 0.25 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.15 |

Distinctive Benefits of Aluminum Elbows for Shipboard Refrigeration

Corrosion Resistance: Exposure to humid or salt-laden atmospheres, continuous temperature fluctuations, and moist refrigerants can accelerate metal deterioration in refrigeration circuits. Marine aluminum alloys specially engineered resist these effects better than conventional metals.

Weight Efficiency: Weight savings from aluminum elbows contribute to overall vessel stability and improve fuel efficiency, paramount in maritime logistics.

Thermal Conductivity: Aluminum’s high conductivity minimizes heat gain in refrigeration lines, which reduces compressor loads and maintains system efficiency.

Ease of Fabrication and Welding: The recommended H32 and H321 tempers allow streamlined weld and installation operations compliant with marine certification standards.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

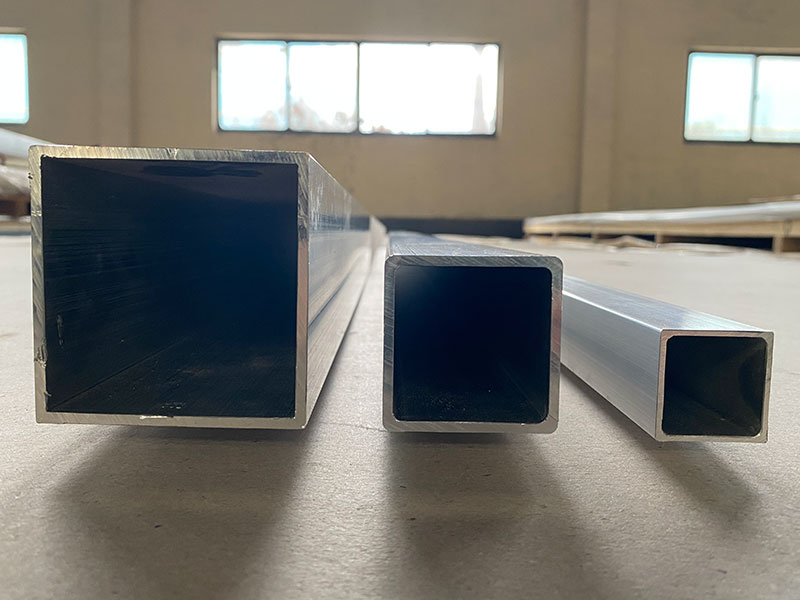

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

Marine Aluminum Pipe Elbow for Emergency Fire Suppression Lines

In the domain of marine safety systems, reliability and durability are paramount. Among the essential components in fire suppression systems onboard ships and offshore platforms is the Marine Aluminum Pipe Elbow used in emergency fire suppression lines.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View DetailsMarine Aluminum Pipe Elbow for Waste Heat Exhaust Systems

In the demanding environment of marine engineering, selecting the right components for waste heat exhaust systems is decisive for both efficiency and durability.

View DetailsAluminum Elbow for Marine Water Purification Systems

Aluminum elbows are specialized pipe fittings designed to change the direction of flow in piping systems, commonly at 45°, 90°, or 180° angles. In marine water purification systems, t.

View DetailsMarine Aluminum Elbow for Pressure Vessel Piping on Ships

Marine aluminum elbows have become an essential component in the pressure vessel piping systems onboard modern ships. As maritime vessels increasingly rely on lightweight, durable, and corrosion-resistant materials, marine aluminum alloys stand out.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details

Leave a Message