Custom Marine Aluminum Elbow for Ship to Ship Fuel Transfer

In the intricate and highly demanding marine environment, efficient and reliable fuel transfer is paramount — especially during ship-to-ship (STS) operations. Central to this process is the often unsung hero: the custom marine aluminum elbow. Engineered specifically to withstand corrosive seawater, pressure variations, and harsh mechanical stresses, this specialized fitting is to ensuring safe, efficient, and leak-free fuel transfer at sea.

The Role of the Marine Aluminum Elbow in Ship-to-Ship Fuel Transfer

In STS fuel transfer operations, pipelines and hoses connect bunkering vessels and receiving ships, creating a flexible fluid dynamic system. Amid these connectors, marine aluminum elbows serve as critical junction components that redirect flow, change pipe direction, and maintain uninterrupted fuel delivery across curved sections preventing pipeline kinks or pressurization issues.

Functions:

- Directional flow management: Allows changing fluid flow direction anywhere from 15° to 180° in a pipeline system.

- Pressure containment: Must withstand varying fluid pressures typical in bunker fuel transfer—up to 150 psi and higher in specific configurations.

- Corrosion resistance: Made from marine-grade aluminum alloys to resist saltwater corrosion, cavitation erosion, and chemical exposure during fuel transfer.

- Structural integrity with lightweight advantage: Minimizes vessel load increase due to aluminum’s inherent strength-to-weight balance compared to steel fittings.

Custom manufacturing enables the fabrication of elbows tailored to exact size, wall thickness, and radius requirements ensuring impeccable integration in STS transfer rigs either on existing pipes or flexible hose connectors.

Custom marine aluminum elbows are manufactured adhering to stringent international marine standards such as ABS (American Bureau of Shipping), DNV GL, and ASTM standards. The fabrication involves well-defined parameters for optimal hydraulic performance and mechanical endurance.

| Parameter | Specification |

|---|---|

| Material | Marine Aluminum Alloy 5083-H321 |

| Elbow Angle Range | Standard: 30°, 45°, 60°, 90°, up to 180° |

| Outer Diameter Extraction | Custom sizes, typically 2” to 24” nominal pipe sizes (NPS) |

| Wall Thickness | Per ASME B31.3 ranging from 3 mm to 12 mm |

| Operating Pressure | Up to 150 psi (1.0 MPa) standard; higher pressure versions available |

| Surface Treatment | Anodizing or powder coating to enhance corrosion resistance |

| Manufacturing Tolerance | ISO 2768-m HB or as per client’s requirement |

The elbow is typically created using hot extrusion and meticulous CNC machining, ensuring tight form tolerances for flange fittings or butt-weld installations based on pipeline or hose fitting standards.

Alloy Details: Aluminum 5083-H321 for Marine Excellence

Aluminum alloy 5083-H321 is most widely employed due to its excellent welding characteristics and superior strength combined with unmatched corrosion endurance in saltwater. This makes it ideal for marine applications including fuel transfer elbows.

| Element | Percentage by Weight (%) |

|---|---|

| Aluminum (Al) | Bal. (approx 91.0 - 94.3) |

| Magnesium (Mg) | 4.0 to 4.9 |

| Manganese (Mn) | 0.4 to 1.0 |

| Iron (Fe) | 0.4 (max) |

| Chromium (Cr) | 0.05 to 0.25 |

| Silicon (Si) | 0.4 (max) |

| Copper (Cu) | 0.05 (max) |

| Zinc (Zn) | 0.25 (max) |

| Titanium (Ti) | 0.15 (max) |

Tempering (H321 Temper): This temper designation implies that the aluminum alloy is stabilized through strain hardening (cold working) and partially annealed. The process reduces susceptibility to creep and stress corrosion cracking—a vital quality for parts under dynamic marine and pressure stresses.

Implementation Standards and Testing for Custom Marine Aluminum Elbows

Marine accessories like aluminum elbows integrated on fuel lines must satisfy mechanical demands:

- Pressure testing: Hydrostatic testing to 1.5 times the maximum operating pressure ensuring material integrity under real-world operational overloads.

- Non-destructive testing (NDT): Dye penetrant and ultrasonic examination verify welded or joined sections free from cracks and defects.

- Corrosion evaluation: Salt spray tests following ASTM B117 confirm corrosion resistance over extensive usage.

- Dimensional accuracy checks: Per ASTM B221 specifications validate exterior dimension uniformity and flange bore correctness aiding interchangeability.

Applications Across Marine and Offshore Installations

Bunkering Operations: Vital elbow fittings allow precise routing of hoses for fuel transfer from tanker decks to fuel manifold connectors, compensating for complex motion between ships due to sea dynamics.

Fuel Supply System Retrofit: Aluminum elbows enable lightweight reconfiguration of onboard piping in older or newbuild ships ensuring compatibility with the latest STS fuel transfer technology.

Emergency Fuel Systems: Their resilience and fault tolerance let them be integral in quick-react indirect fuel pumping lines in offshore platforms or naval vessels.

Related Products

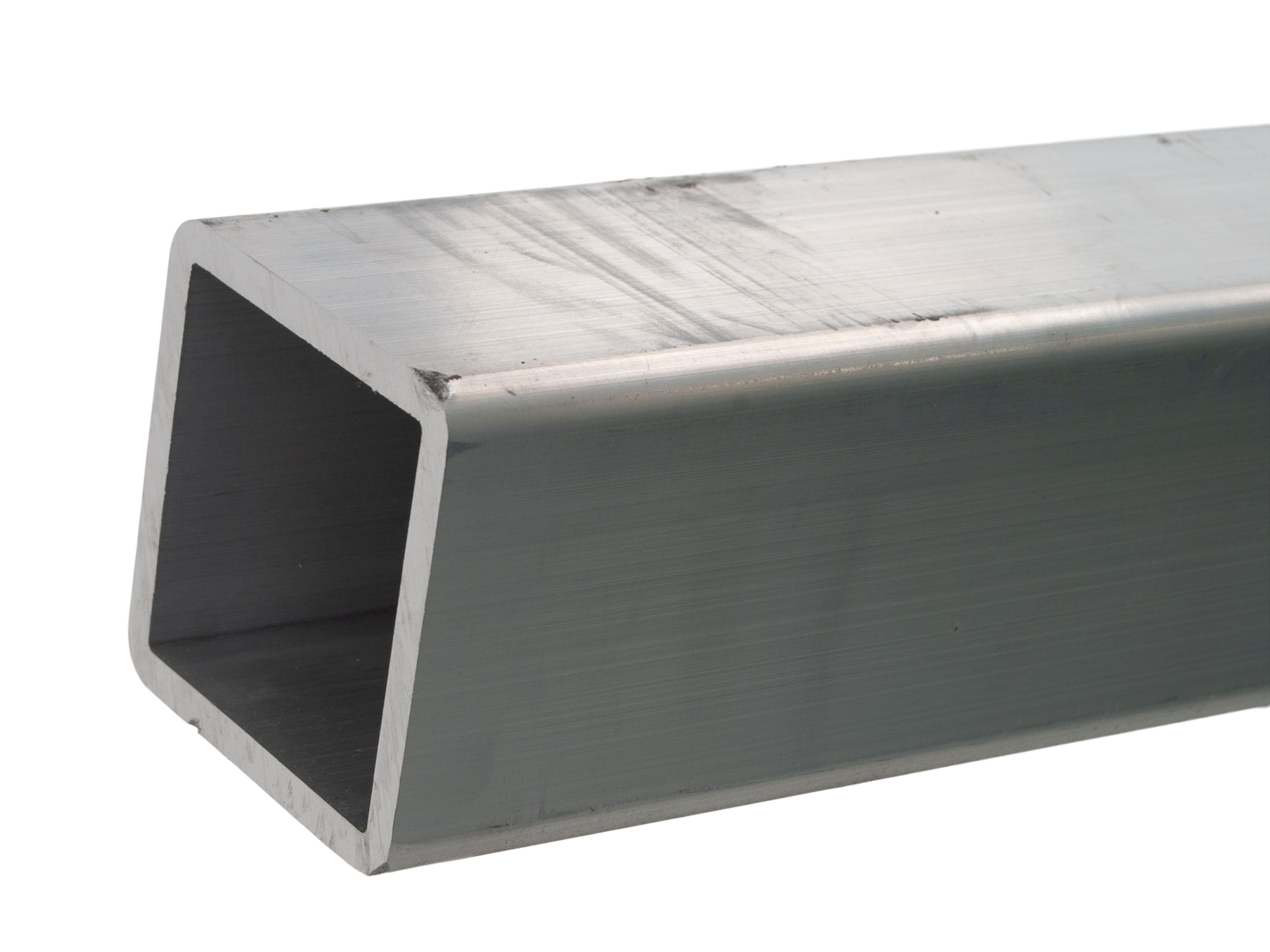

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

Marine Aluminum Elbow for Pressure Vessel Piping on Ships

Marine aluminum elbows have become an essential component in the pressure vessel piping systems onboard modern ships. As maritime vessels increasingly rely on lightweight, durable, and corrosion-resistant materials, marine aluminum alloys stand out.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View DetailsAluminum Elbow for Saltwater Inlet and Outlet Systems

Aluminum elbows play a critical role in saltwater inlet and outlet systems used in marine, industrial, and desalination applications. Manufactured from high-quality aluminum alloys, these fittings are engineered to provide robust, corrosion-resistant.

View DetailsMarine Grade Aluminum Pipe Elbow for Offshore Projects

Marine environments pose unique challenges—including corrosion, mechanical stress, and exposure to harsh elements—necessitating the use of specialized materials and components.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View DetailsAluminum Elbow for Marine Water Purification Systems

Aluminum elbows are specialized pipe fittings designed to change the direction of flow in piping systems, commonly at 45°, 90°, or 180° angles. In marine water purification systems, t.

View Details

Leave a Message