6061 Marine Aluminum Round Bar for Custom Marine Vessel Parts

When it comes to marine vessel construction and maintenance, the materials chosen play an integral part in their functionality, longevity, and structural integrity. Amidst various metal options available, 6061 marine aluminum round bar has garnered a significant reputation owed to its excellent combination of properties, making it the preferred choice for custom marine vessel components.

6061 Marine Aluminum

Aluminum alloys are generally categorized into two classes: wrought and cast. 6061 aluminum is designated as a wrought alloy, characterized by good mechanical properties and atmospheric corrosion resistance. The number "6061" designates a specific strength classification within the series, tailored specifically to bridge engineering, marine environments, automotive and aerospace applications.

What Makes It 'Marine' Grade?

In the nomenclature of aluminum classifications, marine grade alloys primarily pertain to those alloys that possess characteristics that stand up well against seawater corrosion. Especially formulated for saline environments, 6061 achieves perfection by showcasing its resilience against pitting, welding qualities, and advantageous workability.

Composition and Chemical Properties of 6061

Virtually, the robustness of 6061 lies in its impeccable alloy composition. The feasibility of maxing out potential performance relies on its micro-configurations.

| Element | Percentage (%) |

|---|---|

| Silicon (Si) | 0.40 - 0.80 |

| Iron (Fe) | 0.00 - 0.70 |

| Copper (Cu) | 0.15 - 0.40 |

| Manganese (Mn) | 0.15 - 0.80 |

| Magnesium (Mg) | 0.80 - 1.20 |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

| Other Elements(Each) | 0.05 max |

| Other Elements(Total) | 0.15 max |

Beyond its elemental components, 6061 expresses vital thermal and mechanical properties through heat treatment options, typically marketed under T6 temper.

Alloy Tempering

The temper is a treatment that alters assuming conditions that promote specific properties. For instance, 6061-T6 indicates a solution heat-treated process followed by artificial aging. This treatment advance in the development and maximization of overall yield strength, rendering it perfect for price-sensitive structures with demanding applications.

Functions and Applications

6061 marine aluminum round bars are crafted and adapted into numerous applications, making this alloy’s versatility a paramount clarification in material selection:

Structural Components: Often utilized in engine blocks, support beams or hull structures, where lower weight does not compromise strength.

Deck Fittings: Shipping lines and pleasure craft typically apply these bars for making fences, rub rails, and walkways thanks to excellent spray finish vibrations unknown for rust, reducing dampening breaches.

Machined Parts: Technical creativity thrives on using advanced machining; developers design critical small components and precision instruments materialized from 6061, keeping accuracy intact even on reasonably rugged requirements.

Watercraft Components: Embedded within the makings of custom replaceable shafts, brackets, and engine, purely crafted from these alloys holds clients with tight corners hurt apart by corrosion.

Bimini Frames: Custom fits for Bimini Tops lending tents in jet skis representing flexibility in matching shape-applied steel-defying strength in fine details.

Implementation Standards

The usage of 6061 alloy round bars is guided by well-defined standardized implementations, including:

- ASTM B221 with bounds regulating its compliance scope influencing dimensions and tolerances.

- ASTM E387 to further prompt perception molded through direct performance comprehension.

Summation

Related Products

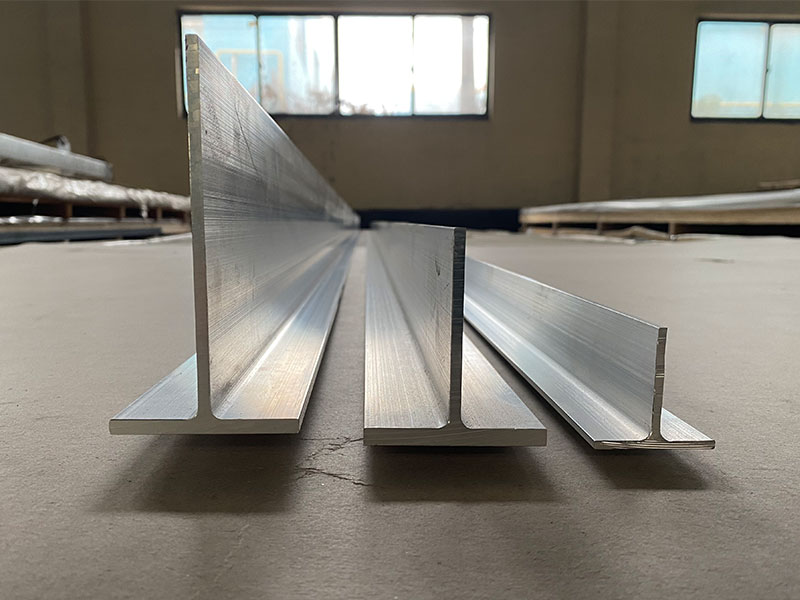

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum Round Bar for Custom Marine Vessel Parts

When it comes to marine vessel construction and maintenance, the materials chosen play an integral part in their functionality, longevity, and structural integrity.

View Details6061 Marine Aluminum Channels for Boat Deck and Frame Construction

6061 marine aluminum channels are extruded structural profiles manufactured from 6061-T6 (or T6511) aluminum alloy, engineered specifically for marine applications such as boat decks, hull framing, stringers, railings, and equipment mounts.

View Details6061 Marine Aluminum Angles for High Strength Coastal Marine Parts

6061 Marine Aluminum Angles are premium-grade structural aluminum components widely used in the marine industry due to their exceptional strength, corrosion resistance, and versatility.

View Details

Leave a Message