Marine Aluminum Bar for Coastal Boat Reinforcement

When considering the perfect material for coastal boat reinforcement, marine aluminum bars emerge as a standout option. Their remarkable blend of strength, corrosion resistance, and weight savings makes them an ideal choice for maritime applications.

The Advantages of Marine Aluminum for Coastal Boat Reinforcement

Lightweight yet Robust: The crucial aspect of marine aluminum bars is their remarkable ability to provide structural strength without adding unnecessary weight. By utilizing alloys that maximize strength without compromising resistance to naval conditions, manufacturers help improve the boat's overall performance.

Corrosion Resistance: Traditional materials, such as steel, often fall short against the choicest enemies of coastal marine environments – salt and moisture. Marine aluminum is coated under stricter parameters guaranteeing resistance to corrosion, elongating the lifespan of vessels and ensuring safer voyages.

Versatile Fabrication Options: These aluminum bars can be efficiently extruded, bead-blasted, and finished into numerous angles depending on fabrication needs without sacrificing material integrity.

Technical Details of Marine Aluminum Bars

Marine-grade aluminum alloys achieve robustness through intricate chemical compositions and precise tempering processes. Below is a detailed table illustrating common marine-use alloys and their respective properties:

| Alloy | Tempering | Mechanical Properties | Density (g/cm³) | Chemical Properties |

|---|---|---|---|---|

| 5052 | H34, H32 | Yield Strength: 193 MPa Ultimate Strength: 310 MPa | 2.68 | Mg: 2.2% Cr: 0.15%-0.35% |

| 5083 | H112 | Yield Strength: 260 MPa Ultimate Strength: 285 MPa | 2.66 | Mg: 4.0-4.9% Mn: 0.4-1.0% |

| 6061 | T6 | Yield Strength: 276 MPa Ultimate Strength: 310 MPa | 2.70 | Mg: 0.8-1.2% Si: 0.4-0.8% |

| 6082 | T6 | Yield Strength: 260 MPa Ultimate Strength: 290 MPa | 2.70 | Mg: 0.6-1.2% Si: 0.7-1.3% |

Implementation Standards

Strict industry standards guarantee marine aluminum is implemented effectively, leading to truly resilient seafaring vessels:

- ASTM B928: Defines the specifications for high-strength aluminum alloys used in marine applications, ensuring consistent quality and performance for safe boat reinforcement.

- ISO 4962: Provides guidelines for hull reinforcement materials in marine environments, reinforcing the long life and consistency deemed vital for regional coastal repairs faced with harsh conditions.

Alloy Tempering and How It Impacts Performance

Tempering dramatically impacts mechanical properties and ultimately decides the applications a marine aluminum bar can endure:

- H34 Temper: A medium-strength temper, suitable for boat decks and similar areas where strengthening against wear is required without drastically increasing weight.

- T6 Temper: Representation of aged materials, providing maximum strength flagship performance while unlikely to experience failing catastrophically when properly rationed.

Related Products

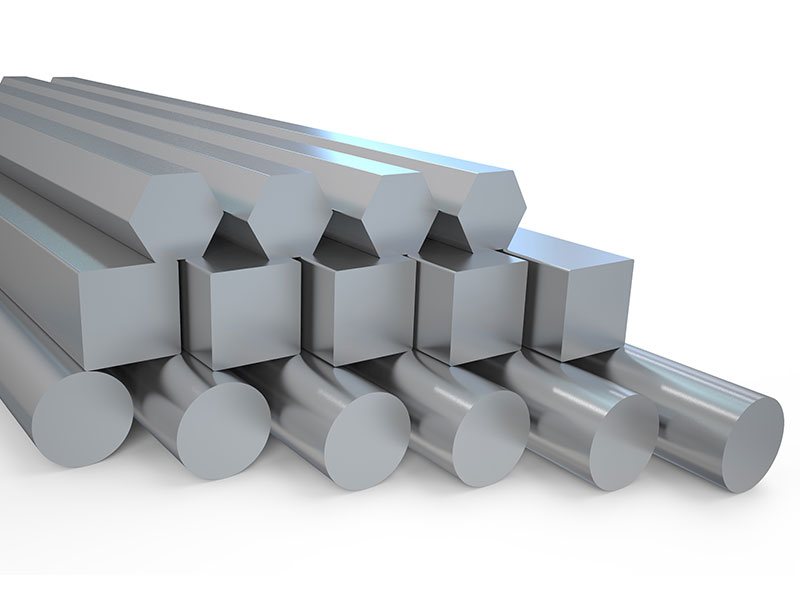

6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

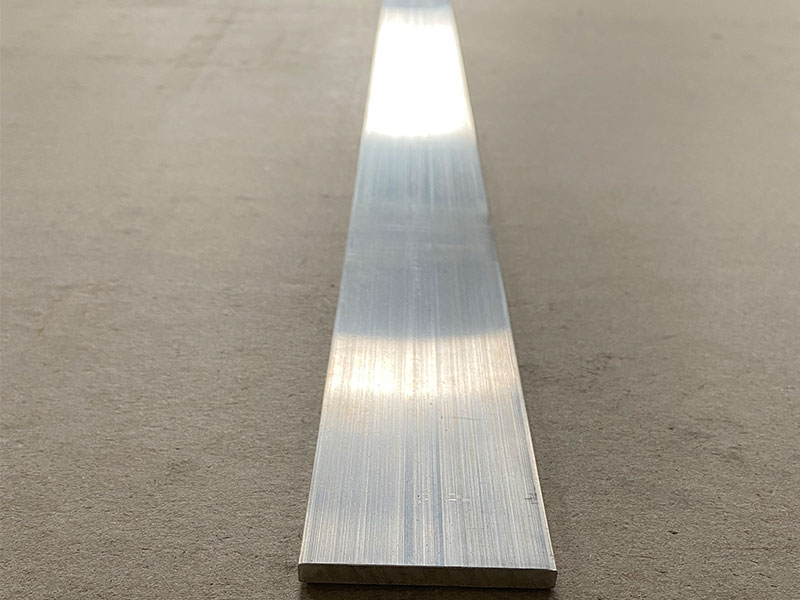

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Aluminum Bar for Saltwater Corrosion Resistant Boat Frames

In the demanding marine environment, selecting the right materials for boat frames is vital to ensuring longevity, performance, and safety. Among the myriad of alloys.

View DetailsMarine Aluminum Hexagonal Bars for Boat Deck and Hull Reinforcement

Superior strength and corrosion resistance of Marine Aluminum Hexagonal Bars designed specifically for boat deck and hull reinforcement. Detailed specifications, alloy tempering conditions, chemical properties, and industry standards explained.

View Details6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details5052 Marine Grade Aluminum Solid Bar for Lightweight Offshore Components

As the maritime industry continues to evolve toward efficiency and performance optimization, the choice of materials plays a pivotal role in determining the success of marine designs.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details

Leave a Message