Marine Aluminum Flat Bar for Saltwater Proof Boat Hull Support

Marine aluminum flat bars are vital materials in the construction of boats, particularly for saltwater environments. These products are engineered to provide robust structural support, ensuring durability and longevity for boat hulls.

Functions of Marine Aluminum Flat Bar

Marine aluminum flat bars serve numerous essential functions in saltwater nautical applications:

Structural Support: The flat bars are used to provide support to the double bottom of the hull and stringer systems, ensuring structural integrity against hydrodynamic stresses.

Corrosion Resistance: These aluminum alloys demonstrate excellent resistance to saltwater's corrosive effects, which is vital for long-term performance and reliability.

Weight Optimization: Marine aluminum is lightweight, making it an ideal choice to enhance speed and fuel efficiency without compromising structural strength.

Easy to Fabricate: Marine aluminum flat bars are capable of being machined and fabricated easily for custom and specialty watercraft designs.

Aesthetic Features: Beyond functionality, these bars can contribute to the sleek design of marine installations, harmonizing form and function.

Applications of Marine Aluminum Flat Bar

Marine aluminum flat bars are employed in a variety of applications, alongside many marine systems such as:

- Boat Hull Construction: Supporting the structure of boats and preventing deformation under adverse environmental loads.

- Gangways and Bridges: Providing sturdy access points along piers and marinas.

- Chassis Support for Trailers: Enhancing the integrity and resistance of trailer designs subjected to frequent exposure to water.

Technical Details

Parameters

To maximize performance and compliance with marine construction standards, a comprehensive overview of the technical parameters surrounding marine aluminum flat bars is significant.

Alloy Tempering Conditions

- Tempering Designation: 5456-H116 / 5086 H32 / 6061-T6 (Common alloys and temper designations available in the marine industry)

- Heat Treatment Process: Solution heat-treated followed by artificial aging

Chemical Properties

The properties of marine aluminum flat bars arise from their alloy composition, primarily determining their resistance to corrosion.

| Alloy Type | Primary Elements | Chemical Composition (wt%) | Uniform Price (per kg) |

|---|---|---|---|

| 5052 | Magnesium and Aluminium | Al ≥ 93.5, Mg 2.5-3.5, Si < 0.25 | $2.50 |

| 5083 | Magnesium and slight Manganese | Al ≥ 90.8, Mg 4.0-4.9, Mn 0.4-0.7 | $2.80 |

| 6061 | Magnesium and Silicon | Al ≥ 90, Mg 0.8-1.2, Si 0.4-0.8 | $3.00 |

Mechanical Properties

| Property | Units | Typical Value (for 5083-H116) |

|---|---|---|

| Yield Strength | MPa | 241 |

| Ultimate Tensile Strength | MPa | 295 |

| Ductility | % | 12-18 |

| Density | g/cm3 | 2.66 |

Implementation Standards

Manufacturers and engineers must adhere to specific industry standards in regards to marine grade aluminum to ensure safety and reliability.

- ISO 2768 - General tolerances and verification.

- ANSI/AAMA 611 - Specification for anodized architectural aluminum finishes.

- ASTM B 928 - Standard Specification for High Magnesium Aluminum-Alloys in Marine Environments.

Choosing the Right Alloy

When selecting the optimal marine aluminum flat bar for boat hull supports, several factors must be considered—load capacity, resistance to corrosion, ease of fabrication, and how the material behaves with aging.

Given its importance in marine construction, the evolution of marine aluminum alloy flat bars presents opportunities for enhancing boat design, increasing operational efficiencies, and offering longevity against the environmentally aggressive conditions present in saltwater applications.

In incorporating marine aluminum flat bars into vessel design, manufacturers not only comply with industry standards but also provide end-users with reliable, high-performing marine infrastructure. Ensuring those involved in marine construction have access to peer-reviewed technical specifications promotes the use of materials that stand the test of time, delivering assured safety and functionality year after year, simply positioning them for the blazing seas ahead.

To learn more about marine aluminum solutions, materials, and specifications suited for your next naval project, reach out to our expert team today!

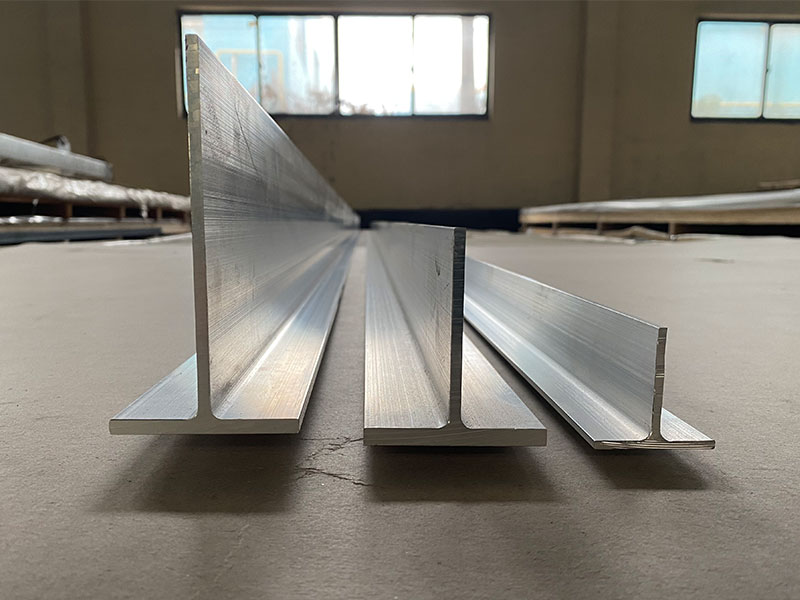

Related Products

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

Marine Aluminum Round Bar for Durable Offshore Ship Parts

In the maritime industry, where durability, corrosion resistance, and structural integrity are paramount, choosing the right material for offshore ship parts is critical.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details5083 Marine Aluminum I Beams for Seawater Resistant Boat Hull Design

Constructing seawater resistant boat hulls demands not only impeccable design but also the right choice of materials engineered for marine environments. Among available metals.

View DetailsMarine Aluminum Z Shaped Sections for Custom Marine Hull Design

Marine Aluminum Z Shaped Sections are precisely engineered aluminum profiles designed to meet the rigorous demands of marine applications, particularly in custom hull fabrication.

View Details5086 Marine Aluminum I Beams for High Strength Marine Engineering

What Makes 5086 Marine Aluminum Special?5086 aluminum alloy is known for its superior corrosion resistance, high anodizing performance, and excellent weldability, making it a popular choice for marine applications.

View Details

Leave a Message