6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options, 6082 marine aluminum bar stands out as a uniquely suited contender for high strength marine components.

6082 Marine Aluminum Bar: The Engineering Breakdown

6082 aluminum alloy belongs to the 6xxx series, known primarily for its balanced strength and corrosion resistance—a result of its primary alloying elements, magnesium and silicon. This synergy forms the temperature-hardening Mg2Si phase, elevating both strength and toughness, critical for components exposed to sea conditions.

6082 marine aluminum bar is a workhorse in our factory, frequently specified for high-strength marine components due to its excellent combination of strength, weldability, and corrosion resistance. However, I've found that achieving optimal performance hinges on careful consideration beyond just the material itself. Pre-processing, such as proper cleaning and surface preparation before welding, is critical to prevent porosity and ensure strong, reliable welds. We've seen instances where seemingly minor deviations in the welding parameters, such as amperage or travel speed, led to significant variations in tensile strength and ultimately compromised the component's lifespan in harsh marine environments. Furthermore, the specific application heavily influences our recommendations; a component experiencing constant dynamic loading, like a boat hull fitting, demands stricter quality control and potentially heat treatment post-welding compared to a less stressed structural element.

Beyond the immediate fabrication process, the long-term implications of environmental exposure is paramount. While 6082's inherent corrosion resistance is a significant advantage, we’ve learned that the choice of coatings and surface treatments significantly impacts its longevity. Saltwater immersion necessitates careful selection of compatible coatings to prevent crevice corrosion and galvanic effects, particularly when 6082 is used in conjunction with other metals. We've had success with powder coating and anodizing, but the optimal choice often depends on the specific component's design and the expected severity of its marine exposure. Regular inspection

Compared to other marine aluminum alloys like 6061 or 5052, 6082 offers superior endurance against stress-induced cracking and fatigue, essential for high-load bearing underside components, structural frames, and fastening systems aboard ships, boats, and offshore platforms.

Chemical Composition and Its Role in Marine Performance

At the heart of 6082 marine aluminum's superior properties lies its chemical composition, tailored to augment corrosion resistance and mechanical integrity. Below is the typical chemical range (Wt%) compliant with EN standards such as EN-AW 6082:

| Element | Range (Wt%) |

|---|---|

| Silicon (Si) | 0.7 – 1.3 |

| Magnesium (Mg) | 0.6 – 1.2 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.10 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.10 |

| Aluminum (Al) | Balance |

This specific alloying ensures excellent resistance to seawater corrosion, a non-negotiable parameter in marine context where saltwater and humidity accelerate material degradation.

Mechanical Properties & Temper Conditions: Crafting Excellence for the Sea

A notable feature of 6082 marine aluminum bars is the variety of temper conditions that optimize strength and ductility per component demands. Common tempers include:

T6 (Solution Heat Treated and Artificially Aged):

Ultimate Tensile Strength: ≥ 310 MPa

Yield Strength (0.2% offset): ≥ 260 MPa

Elongation: 8-12%

T651 (Solution Heat Treated, Stress Relieved by Stretching, and Artificially Aged):Similar mechanical strengths with improved dimensional stability; crucial for marine parts resisting deformation from dynamic loads and vibrations.

Such tempering ensures parts manufactured from 6082 aluminum bars maintain resiliency under fatigue-inducing wave motions and impact loads while resisting stress corrosion cracking, typical with high chloride environments.

Standards and Implementation: Ensuring Quality & Consistency

Manufacturing 6082 marine aluminum bars aligns with stringent norms likealuminum_6082:

- EN 573 / EN 755 — Specifies chemical compositions and dimensions for wrought aluminum alloys.

- ASTM B221 — Governs relevant extruded bar applications in structural uses.

- ISO 6361 — Defines laminated rolled plates essential when high-purity and homogeneous structure matter in marine-grade alloys.

Adhering to these standards guarantees that 6082 alloy bars exhibit the reproducibility needed for precision fabrications such as ship frameworks, railings, and corrosion-resistant fittings.

Why Choose 6082 Aluminum Bar for Marine Applications?

From an aluminum alloy specialist's viewpoint, when safeguarding high-strength, lightweight components within harsh marine settings, 6082 marine aluminum bar offers:

- Exceptional Strength-to-Weight Ratio: Minimizing vessel weight improves fuel efficiency and overall stability.

- Superior Corrosion Resistance: Magnesium and silicon balance act as protective barriers minimizing pitting and general aging impacts.

- Good Weldability and Machinability: Streamlining fabrication and assembly reduce labor costs without sacrificing integrity.

- Durability Under Cyclic Stress: Resisting micro-cracking from vibrations common in prop shafts and housings.

Related Products

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

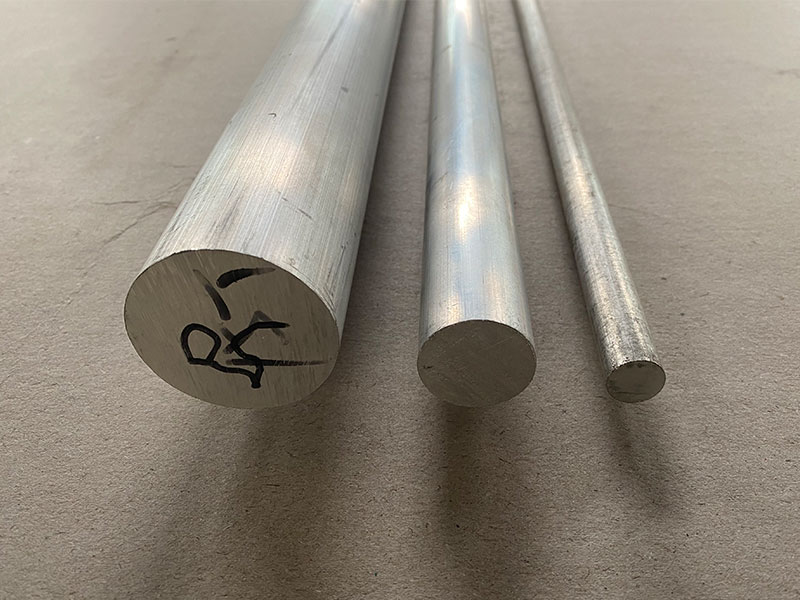

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details

Leave a Message