Marine Aluminum Channels for Boat Frame and Deck Customization

Marine aluminum channels are the quiet backbone of modern boat frame and deck customization. They don’t get the attention that engines or electronics do, but they’re the structural language that lets designers turn ideas into strong, lightweight, corrosion‑resistant reality.

What Makes a Channel “Marine” Instead of Just “Aluminum”?

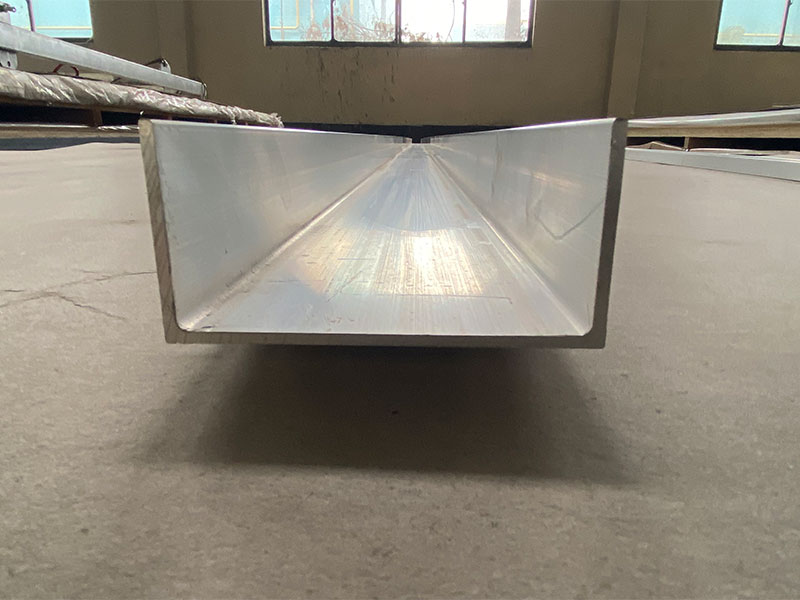

At a distance, an aluminum channel is a simple “C” or “U” shaped profile. Up close, the difference between a general structural channel and a marine aluminum channel comes down to:

- Alloy chemistry tailored for seawater

- Controlled temper for the right balance of strength and formability

- Tight dimensional tolerances for precise fit-ups

- Surface condition compatible with marine coatings or anodizing

Marine service is unforgiving. Saltwater, cyclic loading, vibration, and dissimilar-metals contact all conspire to attack weak points. That’s why marine-grade channels usually come from the 5xxx and 6xxx aluminum families, with specific chemistries and tempers selected for hull and deck environments.

Core Functions of Marine aluminum channels Onboard

From a functional viewpoint, channels act as “load paths” and “attachment tracks” that organize forces and fasteners in a boat.

Structural framing and stiffening

Channels are often used as:

- Deck beams and deck edge stiffeners

- Cabin roof ribs

- Coaming and gunwale stiffeners

- Transom and engine-well reinforcement

The open geometry of a channel puts material away from the neutral axis, which increases moment of inertia relative to its weight. In simple terms, you get more stiffness per kilogram than with flat bar of the same cross‑sectional area.

Mounting rails and modular interfaces

For customization-heavy builds, channels provide a continuous mounting line:

- Sliding/adjustable mounts for seats, coolers, bait stations

- Track for canopies, T‑tops, and radar arches

- Cable and hose runs protected inside the channel web

A well-chosen marine aluminum channel becomes a hidden “bus bar” for hardware: drill once into the channel, not into the hull or deck core repeatedly.

Edge protection and transition zones

Channels also solve small but important design details:

- Clean, reinforced transitions between deck and cabin sides

- Protected edges around hatches and access panels

- Drainage paths when installed as inverted channels along scuppers or cockpit edges

In these applications, the geometry protects laminates or timber from abrasion while offering continuous reinforcement around cut‑outs.

Choosing Alloys: 5052, 5083, 5086, 6061, 6082

From a technical standpoint, the alloy family is the first filter.

5xxx series: Non‑heat‑treatable, corrosion‑focused

These are magnesium‑bearing alloys with excellent marine corrosion resistance and good weldability.

Common marine channel alloys in this family:

- 5052: Good formability, medium strength, ideal for lighter framing, deck trim, and non‑critical stiffeners.

- 5083 / 5086: High strength, excellent corrosion resistance in seawater, widely used in hull plating and heavy structural members. Channels in these alloys are well suited for high-load deck beams, transom frames, and structural supports in workboats and patrol craft.

6xxx series: Heat‑treatable, higher stiffness and machinability

These are magnesium‑silicon alloys used where machining and threaded fasteners dominate:

- 6061: The workhorse structural alloy, especially in temper T6 for high strength. Excellent for precision frames, radar arches, console structures, and bolted assemblies.

- 6082: Similar to 6061 but with slightly higher strength and better performance in some structural applications, especially in European standards.

In many boats, 5xxx alloys are preferred where welding and saltwater immersion dominate, while 6xxx alloys are used where bolted joints, machining, and above‑waterline structures are common.

Tempering: Why “H116” or “T6” Matters

Alloy alone does not define performance. Temper describes the mechanical history of the metal.

Typical marine tempers include:

- H32 / H34: Strain‑hardened and partially annealed. Balanced strength and formability for curved frames and cold‑formed channels.

- H116 / H321: Special tempers for 5xxx plate and profiles intended for marine environments, with improved resistance to exfoliation and stress‑corrosion.

- T5: Cooled from an elevated‑temperature shaping process and artificially aged.

- T6: Solution heat-treated and artificially aged, giving high strength for 6xxx channels used in heavily loaded structures.

From a designer’s perspective, H‑tempers are favored when channels will be bent, rolled, or heavily welded. T6 is ideal when the channel will be machined, drilled, and bolted, and when maximum stiffness is desired in a relatively straight member.

Typical Parameters: Dimensions and Mechanical Properties

Channel geometry is chosen based on span, load, and installation space. Common ranges (values illustrative, not universal):

- Flange width: about 20–150 mm

- Web height: about 20–250 mm

- Wall thickness: about 2–12 mm

mechanical properties for marine channels:

- Yield strength: roughly 125–320 MPa, depending on alloy and temper

- Ultimate tensile strength: roughly 190–350 MPa

- Elongation at break: 8–18% for most marine tempers (important for toughness)

- Elastic modulus: around 69–71 GPa (similar for most aluminum alloys)

When sizing channels for deck beams or cabin roofs, engineers use section modulus and moment of inertia derived from the exact profile. For custom boat work, a practical rule is to prioritize stiffness (deflection control) over sheer ultimate strength; an overly flexible deck feels cheap even if it never fails.

Implementation Standards and Certifications

True Marine aluminum channels are generally produced and certified under recognized standards. Common frameworks include:

- ASTM B221 for aluminum extruded bars, rods, wire, profiles

- EN 755 for extruded aluminum profiles in European markets

- Classification society rules such as DNV, ABS, LR, BV for structural use in classed vessels

- ISO 12215 (small craft – hull construction and scantlings) for performance targets in pleasure and small commercial craft

For builders, this means:

- Traceable mill certificates listing alloy, temper, and batch

- Verified mechanical properties and chemical composition

- Compliance with marine corrosion resistance criteria, especially for 5xxx alloys

Using uncertified, generic architectural channels in a hull or structural deck frame is a false economy; the cost savings are small compared to the risk of premature corrosion or failure.

Chemical Composition Snapshot

Below is an indicative composition table for common marine alloys used in channels. Actual values vary within the allowed range of each standard.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Others / Al |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | ≤0.15 | ≤0.10 | ≤0.03 | Balance Al |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance Al |

| 5086 | ≤0.40 | ≤0.50 | ≤0.10 | 0.20–0.7 | 3.5–4.5 | ≤0.25 | ≤0.25 | ≤0.15 | Balance Al |

| 6061 | 0.40–0.8 | ≤0.70 | ≤0.15 | 0.15–0.4 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | Balance Al |

| 6082 | 0.70–1.3 | ≤0.50 | ≤0.10 | 0.40–1.0 | 0.6–1.2 | ≤0.25 | ≤0.20 | ≤0.10 | Balance Al |

The magnesium content in 5xxx alloys is the main driver of their marine corrosion resistance and strengthening by solid solution. In 6xxx alloys, the Si+Mg combination forms Mg2Si precipitates during heat treatment, giving the high T5/T6 strengths designers rely on.

Application Examples: From Concept to Deck

To see how these details come together, consider common customization scenarios.

Custom deck grid for a sportfishing boat

- Alloy: 5083-H116 channels as deck beams, chosen for welded integration with a 5xxx hull

- Geometry: Deeper channels under high-traffic areas, shallower near cabin sides to save weight

- Function: Stiff, corrosion-resistant support for an aluminum or composite deck, with channel flanges serving as mounting surfaces for hatches and fish boxes

Bolt‑on T‑top and electronics frame

- Alloy: 6061-T6 channels for upright frames and cross beams

- Reason: Strong, stiff, and easy to machine for antenna, radar, and light mounts; minimal welding and mostly bolted joints

- Benefit: Clean cable runs inside channels, reduced visual clutter, and a lightweight but rigid support frame

Workboat gunwale and fender reinforcement

- Alloy: 5086-H32 channels along the sheer line

- Role: Edge reinforcement, tie‑off and fender mount structure, and impact load distribution into the hull

- Added value: A continuous “utility rail” for cleats, fairleads, and lifting points, all connected to a robust structural member

Practical Selection Considerations for Builders and Owners

When choosing Marine aluminum channels for customization, the questions are:

- Will it be welded, bolted, or both? Favor 5xxx for welded, 6xxx for heavily machined and bolted applications.

- Is it submerged, splash‑zone, or dry interior? Prioritize 5xxx with marine tempers for immersion or persistent wet zones.

- How important is stiffness versus forming? Higher temper and deeper sections where deflection must be minimized, softer tempers where bending or rolling is required.

- Are you matching an existing hull alloy? Staying within the same alloy family reduces galvanic potential and improves weld compatibility.

Turning Channels into a Customization Platform

Viewed from a distinctive angle, Marine aluminum channels are not just sections of metal; they’re the modular framework that decides how easily a boat can evolve.

A well-designed network of channels in frames, deck grids, gunwales, and superstructure gives you:

- Predictable load paths

- Clean mounting surfaces almost everywhere you need them

- Reserved internal space for wiring, plumbing, and future upgrades

With the right alloy, temper, geometry, and certified standards behind them, Marine aluminum channels turn boat customization from ad‑hoc drilling and patching into a controlled, structural system that is lighter, stronger, and more durable in saltwater over the long run.

Related Products

Marine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

Marine Aluminum Round Bar for Saltwater Resistant Boat Design

When designing boats destined for saltwater environments, materials selection is paramount for ensuring long-lasting performance and reliable structural integrity.

View DetailsMarine Aluminum Rod & Bar for High Performance Boat Construction

In the demanding field of high performance boat construction, material selection is critical to achieving the perfect balance of strength, weight, corrosion resistance, and durability.

View DetailsMarine Aluminum Round Bar for Marine Vessel Structural Support

Marine aluminum round bars are critical components specifically engineered to meet the demanding requirements of marine vessel structural support. Combining high strength, exceptional corrosion resistance, and excellent weldability.

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details5083 Marine Aluminum Round Bar for Durable Offshore Vessel Parts

When it comes to constructing durable offshore vessel parts, material choice is paramount. Among various options, 5083 marine aluminum round bar stands out as a highly reliable and versatile solution.

View Details5083 Marine Aluminum Angles for Custom Offshore Vessel Reinforcement

Aluminum alloy 5083 marine aluminum angles are a premium-grade aluminum product specifically engineered for demanding marine and offshore environments. Renowned for excellent corrosion resistance, superior strength, and excellent weldability.

View Details

Leave a Message