Marine Aluminum Round Bar for Saltwater Resistant Boat Design

When designing boats destined for saltwater environments, materials selection is paramount for ensuring long-lasting performance and reliable structural integrity. Marine aluminum round bars is know as an essential component in modern saltwater vessel construction, combining exceptional strength, corrosion resistance, and machinability.

Why Choose Marine Aluminum Round Bars for Saltwater Boats?

Saltwater is notoriously corrosive due to its high sodium chloride (NaCl) content, posing a constant threat to marine vessels fabricated with suboptimal materials. Unlike traditional steel and non-marine elements, marine aluminum alloys meticulously balance strength alloys with resistive chemistry, addressing these challenges head-on.

The round bar shape is particularly useful as a foundational stock material for various structural and performance-critical elements in boats, such as stanchions, railings, drive shafts, propeller shafts, shafts for mechanical linkages, and more. The uniform cross-section of round bars simplifies machining while ensuring isotropic strength characteristics aligned with the varied force vectors encountered at sea.

Alloy Composition: The Heart of Saltwater Performance

Marine aluminum round bars typically adopt alloys defined under specifications such as 5052-H32, 5083-H321, and 6061-T6. Here’s a closer look at alloy characteristics, including typical chemical composition (%wt) tailored to enhance seawater resistance:

| Element | 5052 | 5083 | 6061 |

|---|---|---|---|

| Aluminum (Al) | Balance (to 100) | Balance (to 100) | Balance (to 100) |

| Magnesium (Mg) | 2.2–2.8 | 4.0–4.9 | 0.8–1.2 |

| Manganese (Mn) | 0.15–0.35 | 0.4–1.0 | 0.15 max. |

| Chromium (Cr) | 0.15 max. | 0.05–0.25 | 0.04–0.35 |

| Silicon (Si) | 0.25 max. | 0.4 max. | 0.4–0.8 |

| Copper (Cu) | 0.1 max. | 0.1 max. | 0.15–0.4 |

| Iron (Fe) | 0.4 max. | 0.4 max. | 0.7 max. |

Note: Variations are based on alloy temper and standard manufacturer chemistries

The Magnesium content is to corrosion resistance, forming a passive oxide layer that lends protection from seawater interaction. For example, Alloy 5083—with a higher Mg content—delivers outstanding marine corrosion resistance plus excellent strength, making it a preferred choice for thick plate and bars exposed to highly aggressive saltwater.

Tempering: Mechanical Performance Tailored for Marine Conditions

The temper designation highlights how heat treatment impacts the mechanical properties:

- H32 or –H) tempers: Strain-hardened with slight thermal treatment improves toughness while maintaining formability.

- –T6 temper: Solution heat-treated, then artificially aged to attain a strong peak strength state especially favored in aluminum 6061 applications that require automotive or mechanical parts.

- –H321 temper: A strain-hardened and stress-relieved condition applicable in marine alloys like 5083 for optimal form retaining and corrosion performance.

Typical mechanical properties of popular marine round bars (for alloy428, 5052-H32 and 5083-H321) are:

| Alloy-Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|

| 5083 - H321 | 305 | 215 | 16 | 2.66 |

| 5052 - H32 | 228 | 193 | 12 | 2.68 |

| 6061 - T6 | 310 | 275 | 12 | 2.70 |

Standards Guide the Quality and Performance

Proper adherence to manufacturing and quality standards is absolutely critical. Marine aluminum round bars often conform to:

- ASTM B211: Covers aluminum and aluminum-alloy drawn and extruded round bars, rods, and wires.

- ABS and DNV-GL classification rules: For marine and offshore structural parts.

- ISO 6361: For wrought aluminum sovereign standards.

- SAE J454 & J989: Specific alloy temper requirements aimed at evaluating mechanical parameters and testing fatigue performance.

Definitely, certification against these standards ensures consistent corrosion resistance, strength reproducibility, and long-term performance in salty or basinal ocean environments.

Applications and Practical Usage in Marine Contexts

Marine aluminum round bars are employed in diverse roles onboard saltwater vessels, including:

- Structural columns and tro\/re steps because of cost-effective feeding material dimension for bending & machining.

- Lift shafts, motive rails, actuating rods benefiting from additive corrosion tolerance due to seamless oxide scales.

- Cleather pins and fastening assemblies, isolating environmental wear at mechanical joints.

- Pulley shafts and hinge rods for canoe, fishing, speed boats which aren’t exposed to rough metal cracking.

- Security cage shafts and marine hardware used in penetrations.

- Fabrication of special corrosion proof brackets and mounts, reducing material substitution beyond stainless steel.

Wrapping Up: Reliable Strength and Lasting Saltwater Resistance in One Bar

For saltwater boat builders, incorporating marine aluminum round bars unlocks remarkable corrosion resistance married to lightweight but strong structural benefits. Optimal alloy options proved through many years—when supplied to AMS or ASTM specifications and carefully tempered—guarantee decades worth of structural integrity with minimized maintenance.

Choosing marine aluminum round bar not only modernizes structural components but delivers outstanding reliability, cost-effectiveness, and design versatility that engineers need to build vessels capable of enduring the harshest ocean conditions comfortably.

To learn more or discuss custom sourcing options of marine aluminum round bars for your next saline watercraft project, contact our specialists at Haomei Aluminum CO., LTD., Inc. – specialists in premium marine alloys.

References

- ASM Handbook – Aluminum and Aluminum Alloys.

- ASTM B211 - Standard Specification for Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod, and Wire.

- DNV GL Ship Rules Module 6 Aluminum in Ship Building

- Aluminum Association: The Aluminum Alloy Temper Designation System.

By the blend of chemistry, material science, standards, and application of marine aluminum round bars, you ensure your designs thrive in the challenging saltwater arena. This knowledge is pivotal for advancing marine technology toward safer, lighter, and longer-lasting vessels.

Related Products

5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

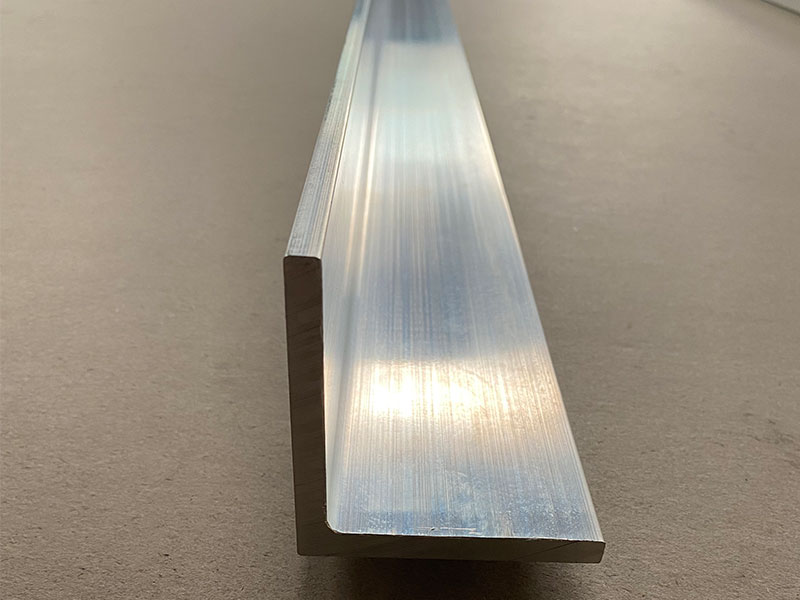

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details5083 Marine Aluminum Channels for Lightweight Marine Vessel Design

5083 Marine Aluminum Channels for Lightweight Marine Vessel Design: A Perfect Fusion of Strength, Durability, and Corrosion ResistanceIn the evolving world of marine vessel design, the quest for materials that offer unbeatable strength.

View DetailsMarine Aluminum Z Shaped Sections for Seawater Proof Engineering Solutions

Unmatched advantages of Marine Aluminum Z Shaped Sections in seawater proof engineering solutions. Learn about their technical functions, applications, and why they are indispensable for marine infrastructure.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details6061 Marine Aluminum Channels for Custom Marine Component Fabrication

When it comes to constructing reliable, corrosion-resistant, and durable marine structures, the choice of material is pivotal. Among several options.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details

Leave a Message