5083 Marine Aluminum Round Bar for Durable Offshore Vessel Parts

When it comes to constructing durable offshore vessel parts, material choice is paramount. Among various options, 5083 marine aluminum round bar stands out as a highly reliable and versatile solution. This specific aluminum alloy combines excellent corrosion resistance, superior mechanical strength, and exceptional weldability—essential characteristics for materials exposed to harsh marine environments.

Why 5083 Aluminum?

5083 aluminum belongs to the magnesium-aluminum family of alloys. Its popularity in marine applications stems from its outstanding performance in seawater resistance and ability to withstand the stresses common in offshore settings. Unlike standard aluminum, which can succumb quickly to corrosion and fatigue, 5083 maintains integrity over long periods, making it a preferred material for critical vessel parts.

Technical Composition and Chemical Properties

the backbone of this alloy helps in appreciating its performance features. The chemical composition of 5083 marine aluminum adheres strictly to marine industry standards and comprises the following elements:

| Element | Content (%) Range | Contribution to Alloy Properties |

|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | Enhances strength and corrosion resistance |

| Manganese (Mn) | 0.4 – 1.0 | Improves corrosion resistance and toughness |

| Chromium (Cr) | 0.05 – 0.25 | Increases resistance to corrosion and stress corrosion cracking |

| Iron (Fe) | ≤ 0.4 | Typically a minor impurity |

| Silicon (Si) | ≤ 0.4 | Controls grain structure growth |

| Copper (Cu) | ≤ 0.1 | Maintains high corrosion resistance |

| Zinc (Zn) | ≤ 0.25 | Impurity; kept minimal for durability |

| Aluminum (Al) | Balance (~91.85%) | Provides machinability and foundational matrix |

The precise balance ensures that 5083 maintains nodal strength with yet workability—for round bar fabrication.

Tempering Conditions for Marine Aluminum Round Bars

The tempering condition significantly influences the mechanical properties of 5083 marine aluminum round bars. For use in offshore vessel settings, the following temper is predominant:

- H111 Temper: Utilizes strain-hardened proprietary treatment, balancing ductility and tensile strength, providing resilient behavior under mechanical and ambient marine loads. The H111 temper enables easy forming without compromising corrosion resistance.

Optional tempering variations like H116 or H321 also exist which emphasize anodic resistance and stress corrosion cracking mitigation through controlled recrystallization/stabilization treatment. Choosing the proper temper should correlate with part geometry and offshore operational conditions.

Implementation Standards for Quality and Performance

Ensuring the quality and suitability of 5083 round bars for offshore marine use requires compliance with these industry standards:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate that informs material integrity tests and compositional benchmarks.

- AMS-QQ-A-250/12: Aerospace Material Specifications delineate the chemical personalized analysis required for high-quality 5083 alloys.

- ISO 6361 – Aluminium and aluminium alloys — Sheet, strip and plate: Controls production consistency across grades, including those used for mill handling into round bars.

- ASME SB209: Applied in constructing marine pressure vessels that might involve 5083 alloys—critical for pressure durability assessment.

Every batch undergoes stringent testing under these standards. Chemical analysis is complemented with tensile strength, yield strength, elongation, and hardness evaluations, confirming each batch meets or exceeds marine industry safety and performance criteria.

Application in Offshore Vessel Parts

5083 marine aluminum round bars excel wherever mechanical runtime and corrosion diminution are non-negotiable:

- Drive shafts: Non-ferrous material resists galvanic corrosion near wetted shafts.

- Coupling components: Machinability allows for tight tolerance movements.

- Fasteners and connectors: Structural strength ensures maintenance-free deck assembly.

- Hydraulic cylinders and fittings: Lightweight yet highly resilient in cyclic load applications.

The alloy’s outstanding ability to form deep structures and weld securely adds to the scope ranging from rudder posts to integral structural stiffeners—availing durability to even the harshest sea ambient, such as salt spray, temperature fluctuations, and mechanical abrasion from debris and waves.

Related Products

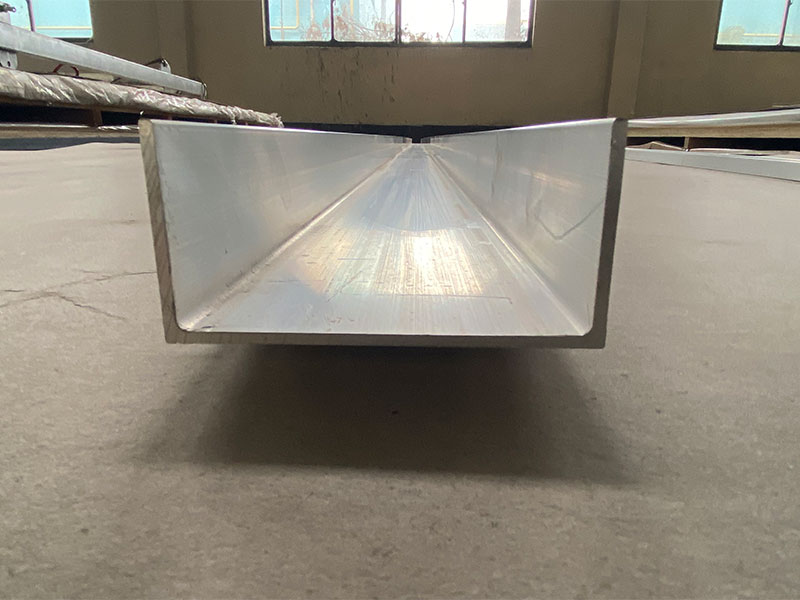

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details5083 Marine Aluminum Channels for Offshore Platform Construction

In the demanding world of offshore platform construction, material selection forms the backbone of structural integrity, durability, and performance. With increasing emphasis on lightweight and corrosion-resistant materials.

View Details5083 Marine Aluminum Round Bar for Durable Offshore Vessel Parts

When it comes to constructing durable offshore vessel parts, material choice is paramount. Among various options, 5083 marine aluminum round bar stands out as a highly reliable and versatile solution.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details

Leave a Message