Marine Aluminum Round Bar for Marine Vessel Structural Support

Marine aluminum round bars are critical components specifically engineered to meet the demanding requirements of marine vessel structural support. Combining high strength, exceptional corrosion resistance, and excellent weldability, these aluminum round bars provide reliable performance under harsh marine environments.

Marine vessels demand materials that withstand continuous exposure to seawater, variable load stresses, and mechanical wear. Our Marine Aluminum Round Bars are optimized to meet these challenges, aiding in constructing robust vessel frames, supports, and braces that ensure vessel safety and longevity.

Advantages:

- Superior seawater corrosion resistance

- High strength-to-weight ratio for optimized structural support

- Excellent fabrication, welding, and machining properties

- Enhanced durability for long service life

Chemical Composition

The alloy used in our marine aluminum round bars is generally based on the 5xxx series (notably 5083 or 5086 alloy) known for superior marine properties.

| Element | Typical Range (% by Weight) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Others | < 0.15 |

Note: Exact composition varies based on specific grades such as 5083 or 5086.

Mechanical Properties

The deliverable mechanical strength allows these bars to handle high stresses while maintaining flexibility, critical under dynamic loading conditions on marine vessels.

| Property | Typical Value | Test Standard |

|---|---|---|

| Ultimate Tensile Strength (MPa) | 300 - 350 | ASTM B308 |

| Yield Strength (MPa) | 145 – 215 | ASTM B308 |

| Elongation (%) | ≥ 12 | ASTM B308 |

| Hardness (Brinell HB) | 60 - 80 | ASTM B308 |

| Density (g/cm³) | 2.66 | |

| Modulus of Elasticity (GPa) | ~70 |

Technical Specifications

| Parameter | Description/Value |

|---|---|

| Alloy Series | 5xxx (Primarily 5083/5086) |

| Temper | O, H112, H321 (Soft to strain-hardened) |

| Diameter Range | 10 mm to 200 mm (custom sizes available) |

| Length | Standard cut lengths or customizable |

| Surface Finish | Mill finish, prepped for marine painting |

| Heat Treatment | Stress relieved, natural or strain hardened |

| Certification | ABS, DNV, LR, BV available |

Performance and Benefits

| Feature | Benefit for Marine Applications |

|---|---|

| Corrosion Resistance | Excellent durability against saltwater corrosion |

| Strength-to-Weight Ratio | Reduces vessel weight, increasing fuel efficiency |

| Weldability | Allows for strong, sound joints in vessel frames |

| Fatigue Resistance | Withstands cyclic loading and harsh vibrations |

| Padding and Impact Resistance | Less prone to cracking under impact and heavy loads |

Applications in Marine Vessel Structural Support

Our Marine Aluminum Round Bars are highly versatile and used in multiple critical applications onboard marine vessels, such as:

- Hull framing: providing internal vessel strength and maintaining hull integrity.

- Deck supports and beams: ensuring platforms and decks remain stable under variable heavy loading.

- Masts and towers: maintaining structural durability for sailing functions or mechanical supports.

- Bulkheads and partitions: facilitating corrosion-resistant structural divisions inside the vessel.

- Ship superstructures and reinforcements: increasing the light weight strength performance of on-deck structures.

Why Choose Our Marine Aluminum Round Bars?

| Customer Priority | How the Product Performs |

|---|---|

| Long service life | 5xxx alloys resist pitting and general corrosion in sea water. |

| Cost-effectiveness | Less maintenance, reduced replacement costs over time. |

| Structural integrity | Meets tight tolerances and major marine certification standards. |

| Ease of Fabrication | Smoother welding and machining for faster turnaround. |

| Environmental Resistance | Performs excellently in marine atmospheres and temperature cycles. |

Related Products

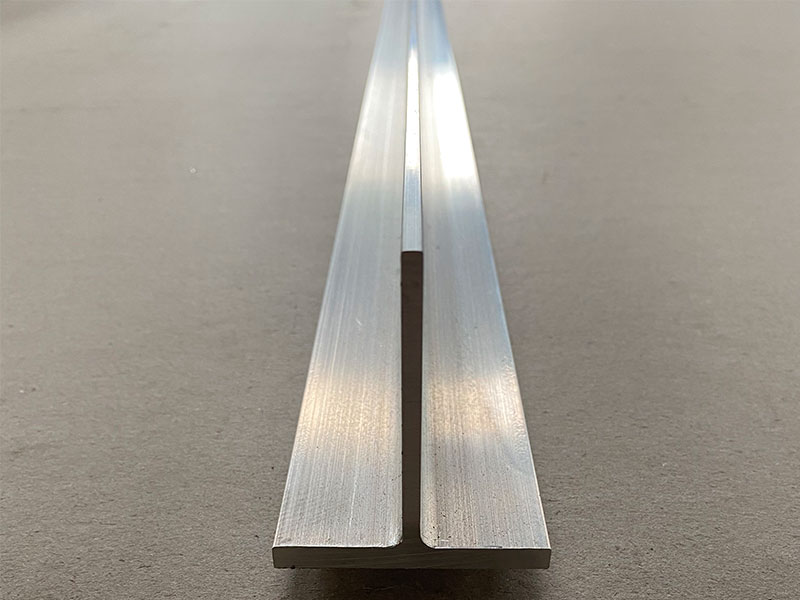

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

5083 Marine Aluminum Round Bar for Custom Boat Hull Design

Designing the perfect boat hull involves a harmony of creativity, functionality, and the right materials. When it comes to marine engineering, 5083 Marine Aluminum Round Bar stands tall, due to its strength, corrosion resistance.

View Details5083 Marine Aluminum Z Shaped Sections for Boat Frame and Hull Customization

When it comes to marine structures, the choice of materials is crucial for durability, performance, and safety. One material that consistently stands out in the maritime industry is 5083 marine aluminum.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View DetailsMarine Aluminum Round Bar for Custom Marine Vessel Construction

Our premium Marine Aluminum Round Bars, specially engineered for custom marine vessel construction. Explore detailed specifications, alloy compositions, temper conditions, and industry standards that ensure superior corrosion resistance, structural integr

View DetailsMarine Aluminum Round Bar for Marine Vessel Structural Support

Marine aluminum round bars are critical components specifically engineered to meet the demanding requirements of marine vessel structural support. Combining high strength, exceptional corrosion resistance, and excellent weldability.

View Details

Leave a Message