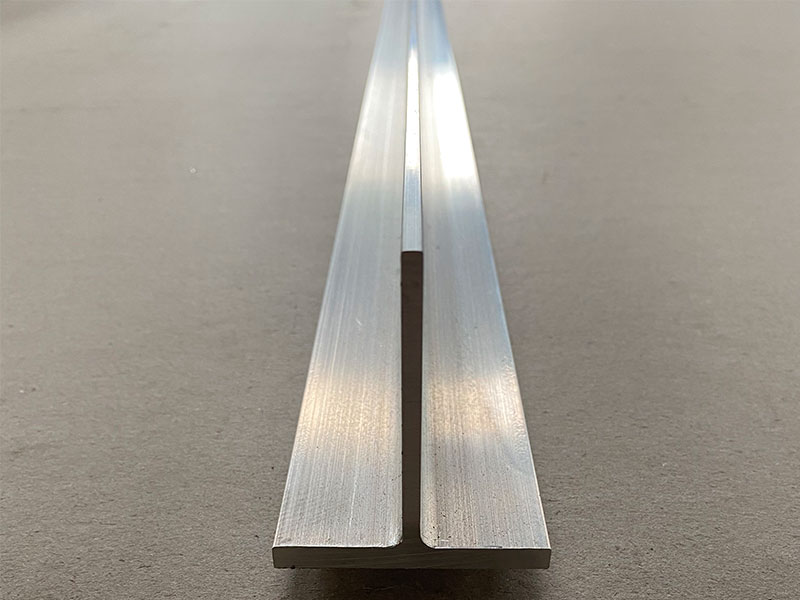

5083 Marine Aluminum Z Shaped Sections for Custom Marine Boat Parts

When it comes to constructing durable, lightweight, and corrosion-resistant components for marine vessels, material selection is crucial. 5083 Marine Aluminum Z Shaped Sections offer an optimal combination of strength, formability, and excellent resistance to seawater corrosion, making them a prime choice for custom marine boat parts.

The 5083 aluminum alloy is part of the 5xxx series, known for its exceptional corrosion resistance, especially in marine environments where chloride exposure is prevalent. When fabricated into Z-shaped sections, the material offers enhanced structural integrity in designs requiring complex profiles and load distribution.

Z shaped sections, with their characteristic geometry, are widely used to provide framing, edging, and reinforcement in custom boat manufacturing, ensuring stability without excessive weight gain.

Features of 5083 Marine Aluminum Z Shaped Sections

| Feature | Description |

|---|---|

| High Corrosion Resistance | 5083 alloy provides excellent resistance to seawater and salt spray corrosion. |

| Lightweight Strength | Strong yet lighter than steel, enabling weight efficient structural support. |

| Good Weldability | Easily welded by common methods including TIG, MIG, and spot welding. |

| Excellent Formability | Can be bent or shaped into precise Z-section profiles without cracking. |

| Durability | Outstanding resistance to intergranular corrosion and stress corrosion cracking. |

| Cost-Effectiveness | Reduced maintenance costs owing to resistance properties lengthening service life. |

Chemical Composition of 5083 Alloy

The chemical makeup of 5083 alloy is carefully controlled to maximize its mechanical properties and corrosion resistance. The table below depicts the standard elemental composition for this alloy, per ASTM B209 / EN 485 standards.

| Element | Weight % Range |

|---|---|

| Aluminum (Al) | Balance (Min 92%) |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Technical Specifications for 5083 Marine Aluminum Z Sections

| Parameter | Value |

|---|---|

| Alloy Grade | 5083 |

| Surface Finish | Mill finish / Painted / Anodized* |

| Section Shape | Z-shaped |

| Thickness Range | 3 mm – 15 mm (customizable) |

| Width | Typically 30 mm – 200 mm |

| Length | Standard: 6 m or 12 m (cut to size available) |

| Density | 2.66 g/cm³ |

| Tensile Strength (Yield) | ~215 MPa |

| Tensile Strength (Ultimate) | 290 MPa |

| Elongation at Break | 12% – 16% |

| Modulus of Elasticity | 70 GPa |

| Corrosion Resistance | Excellent in marine environments |

| Weldability | Excellent |

* Surface finishes can be customized for enhanced aesthetics or additional protective layers.

Applications of 5083 Marine Aluminum Z Shaped Sections

The unique characteristics of 5083 marine aluminum Z shaped sections enable a wide range of marine-specific uses, including:

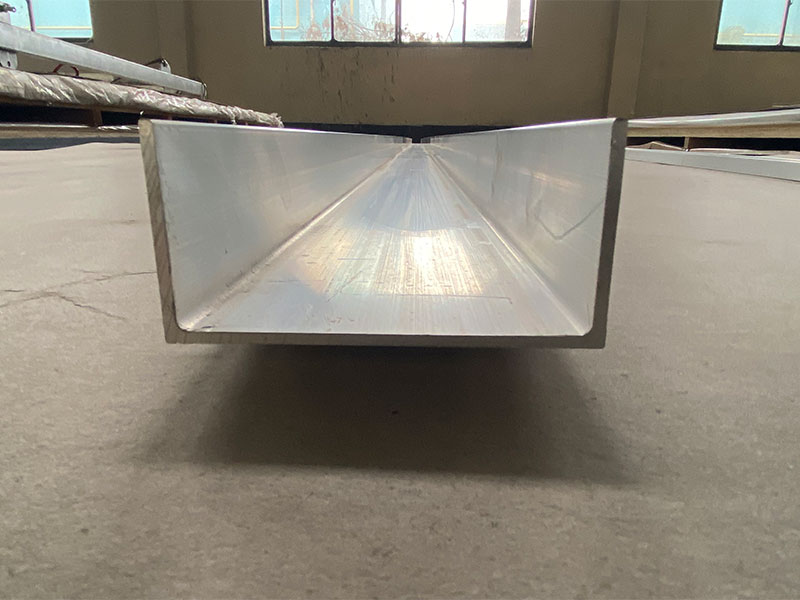

Custom Frame Structures

For vessel hull reinforcements where sectional strength and light weight trump materials like steel.Boat Part Fabrications

Ideal for components including bulkheads, stiffeners, stringers, and edging profiles requiring durable and formable material.Corrosion-Resistant Assemblies

Critical for exposed parts printing against seawater degradation, including ladder stringers, mounting channels, and protection fenders.Panel Supporting Members

Support structures for decks and side panels underpinning boats and submersibles performing in harsh sea conditions.

5083 Marine Aluminum Z Shaped Sections blend superior corrosion resistance, high mechanical strength, and formability, perfect for designing and building tailor-made marine boat components. This material substantially extends service life and lowers maintenance requirements on seawater-exposed structures and custom constructions.

If you are looking to provide your marine project with reliable anodized or plain lightweight structural aluminum with excellent fatigue and corrosion properties, these Z shaped sections offer both versatility and performance requiring rigorous structural design considerations.

For inquiries, custom profile orders, or technical assistance on 5083 Marine Aluminum Z shaped sections, please contact our aluminum supply experts directly.

Related Products

Marine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

5083 Marine Aluminum Channels for Coastal Marine Engineering Projects

In the realm of coastal marine engineering, material selection is crucial for ensuring the durability, performance, and safety of structures exposed to harsh sea environments.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details5083 Marine Aluminum Z Shaped Sections for Custom Marine Boat Parts

When it comes to constructing durable, lightweight, and corrosion-resistant components for marine vessels, material selection is crucial. 5083 Marine Aluminum Z Shaped Sections offer an optimal combination of strength, formability.

View Details5083 Marine Aluminum Round Bar for High Strength Offshore Reinforcements

In the demanding world of offshore engineering, materials must withstand severe environmental conditions without compromising structural integrity. One such pivotal material is the 5083 Marine Aluminum Round Bar.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 Marine Aluminum Channels for Lightweight Marine Vessel Design

5083 Marine Aluminum Channels for Lightweight Marine Vessel Design: A Perfect Fusion of Strength, Durability, and Corrosion ResistanceIn the evolving world of marine vessel design, the quest for materials that offer unbeatable strength.

View Details

Leave a Message