Marine Aluminum Elbow for Offshore Oil Spill Containment Systems

Marine Aluminum Elbow for Offshore Oil Spill Containment Systems: Functions, Applications, and Technical Insights

In the demanding and often harsh environment of offshore oil spill containment systems, every component requires superior performance, outstanding corrosion resistance, and reliable structural integrity. Among these essential components, the Marine Aluminum Elbow plays a critical role in ensuring operational efficiency and safety.

Working with marine-grade aluminum, especially for critical applications like oil spill containment, offers a unique blend of challenges and rewards. The elbows we produce for these systems must withstand incredibly harsh conditions – salt spray, extreme temperature fluctuations, and potential impacts from debris. We're not just talking about meeting a spec; we're talking about ensuring the integrity of a system that could be the difference between a manageable environmental disaster and a catastrophic one. My team and I constantly refine our processes, focusing on superior welding techniques to guarantee leak-free joints and new alloys to enhance corrosion resistance. The weight savings offered by aluminum compared to steel are significant in offshore operations, meaning lower transportation costs and easier deployment in emergency scenarios. It's a responsibility we take very seriously, knowing our work directly impacts environmental protection.

Personally, I find the meticulous nature of the work incredibly satisfying. It's not just about mass production; each elbow is rigorously inspected, tested for fatigue strength and pressure tolerances, and meticulously documented. Seeing the final product, knowing its crucial role in protecting our oceans, brings a deep sense of purpose. The constant drive for improvement – whether it's through innovative joining methods, improved quality control, or new, even more resilient aluminum alloys – keeps the work exciting and intellectually stimulating. We're not just manufacturing elbows; we’re building a critical component in a system designed to mitigate one of the most devastating environmental threats we face. That weight

A Marine Aluminum Elbow is a precisely engineered pipe fitting designed to connect two pipe segments at an angle — commonly 45°, 90°, or even custom bends — used in fluid transport systems on offshore platforms. These elbows must handle dynamic marine conditions, chemical exposures like hydrocarbons and seawater, and physical stresses.

Aluminum alloys specifically tailored for marine use become the material of choice — combining low weight, excellent corrosion resistance, and specific mechanical properties tailored via alloy tempering processes.

Functions of Marine Aluminum Elbow in Offshore Oil Spill Containment Systems

Flow Direction Modification & Continuity:Oil spill containment involves channeling spilled fluids to recovery systems promptly, often around complex offshore platform geographies. The elbow enables fluid redirection without causing significant turbulence or drops in flow efficiency, ensuring controlled guidance of the fluid stream to skimmers, booms, and storage units.

Seamless Integration with Marine Aluminium Piping:Containment pipes are typically constructed from marine-grade aluminum alloys due to their resistance to saltwater corrosion and maintaining strength under cyclic loads. The elbow maintains mechanical and chemical compatibility within this network versus more vulnerable metals.

Pressure & Stress Management:Offshore conditions subject pipes and fittings to varying pressure cycles, vibrational states, and mechanical bends due to waves and equipment operation. The aluminum elbow bears these stresses; optimized for fatigue resistance corresponding to its alloy and temper condition improves service lifespan significantly.

Technical Parameters and Implementation Standards

Material Alloy:The most commonly used marine aluminum alloy for elbows in offshore applications is 5083-H321 or 5052-H32, defined in accordance with ASTM B928 / ASME B16.9 standards. Both provide superb corrosion resistance and mechanical strength suited to marine environments.

| Parameter | Typical Value | Explanation / Standard |

|---|---|---|

| Alloy | 5083-H321 / 5052-H32 | Common marine grades, per ASTM B928 |

| Yield Strength | ≥275 MPa (typical) | Dependent on alloy temper |

| Tensile Strength | 290 - 350 MPa | Structural strength requirement |

| Modulus of Elasticity | ~70 GPa | Stiffness for stress and bending analysis |

| Density | 2.66 g/cm³ | Lightweight advantage |

| Elongation at Break | 12 - 17 % | Ductility under loading |

| Corrosion Resistance | Excellent in seawater | Passivation via Mg and Cr content |

Dimensional Standards & Fabrication:Marine aluminum elbows conform mainly to ISO 4780 (fittings for ship pipelines), AMSE B16.9 (factory-made wrought steel butt-welding fittings - used here as reference due to similar machining/fabrication requirements). This standardization ensures fitment with the pipeline systems, plus weldability and pressure tolerance.

Temper Conditions:

- H321: Strain Hardened and stabilized (5083 alloy) yielding resistant temper suited to removing residual stresses.

- H32: Stabilized strain hardened condition for 5052 alloy, optimizing toughness and corrosion resistance.

Chemical Composition of 5083 & 5052 Marine Aluminum Alloys

| Element | 5083 Aluminum (%) | 5052 Aluminum (%) |

|---|---|---|

| Aluminum (Al) | Balance (about 93-97) | Balance (~97%) |

| Magnesium (Mg) | 4.0 - 4.9 | 2.2 - 2.8 |

| Manganese (Mn) | 0.4 - 1.0 | 0.1 - 0.5 |

| Chromium (Cr) | 0.05 - 0.25 | 0.15 - 0.35 |

| Iron (Fe) | Up to 0.4 | Up to 0.4 |

| Silicon (Si) | Up to 0.4 | Up to 0.25 |

| Copper (Cu) | Up to 0.1 | Up to 0.1 |

Magnesium content notably enhances corrosion resistance in seawater, addressing pitting issues that plague steel fittings — a benefit where exposure to saltwater aggravates chemical breakdown and mechanical failure.

Application Cases in Offshore Spill Containment

1. Boom Connection and Skimmer Systems:Marine aluminum elbows are fundamental to the flexible piping and tubing network enabling quick redirection of floating oil towards containment and collection mechanisms. The elbow ensures system adaptability to wave and wind dynamics while maintaining flow reliability.

2. Temporary Containment System Deployment:Due to aluminum’s lightweight nature, ELbows ease quick setup and teardown of containment piping in emergent oil spills, where rapid deployment—as in emergency response gear or remotely operated vehicles (ROVs)—is imperative.

3. Specialized Pipeline Networks for Fluids & Gases:Beyond liquid oil, these fittings also serve air and ventilation circuits required in monitoring and separation equipment onboard installation-related containment machinery.

Related Products

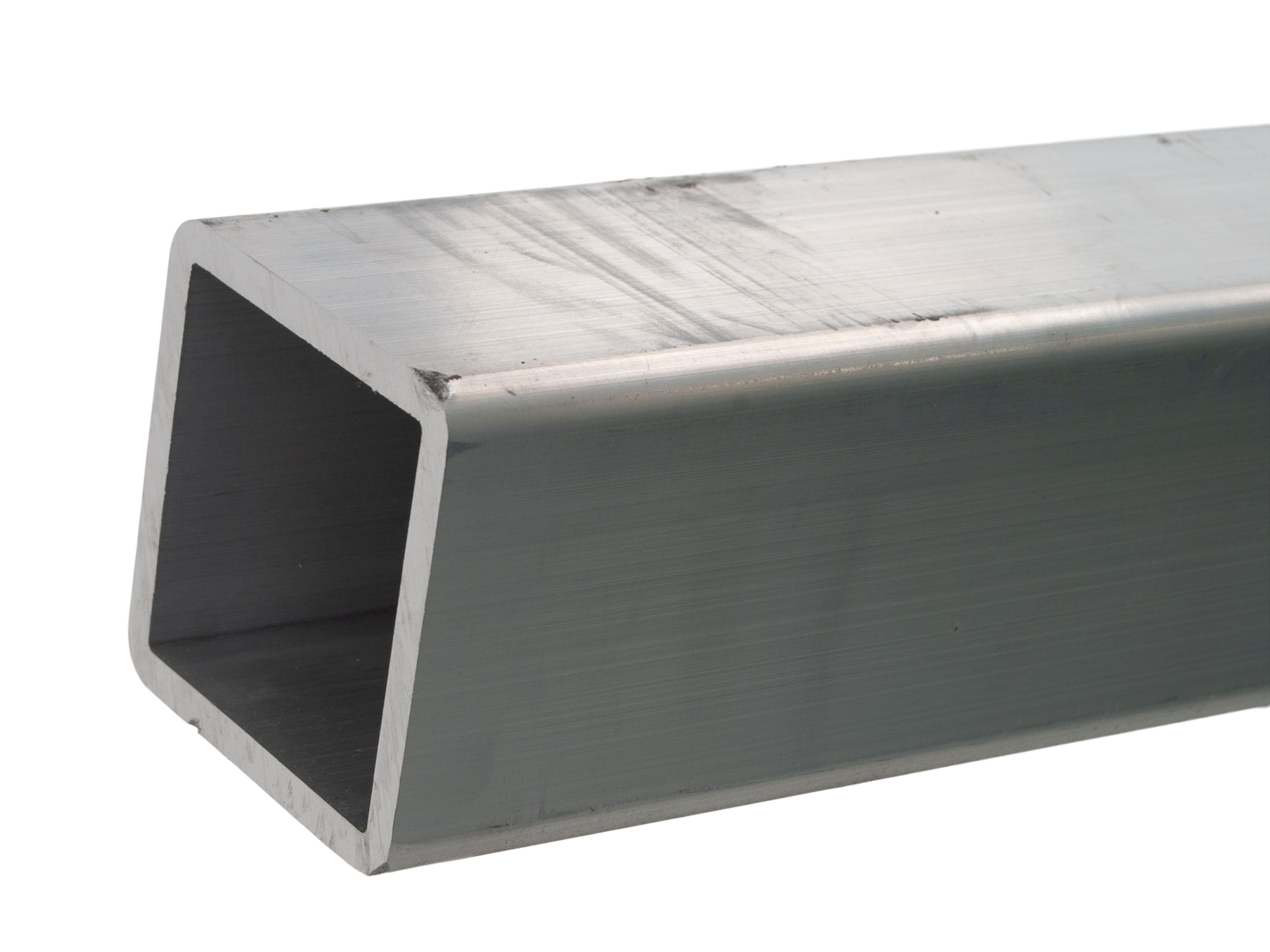

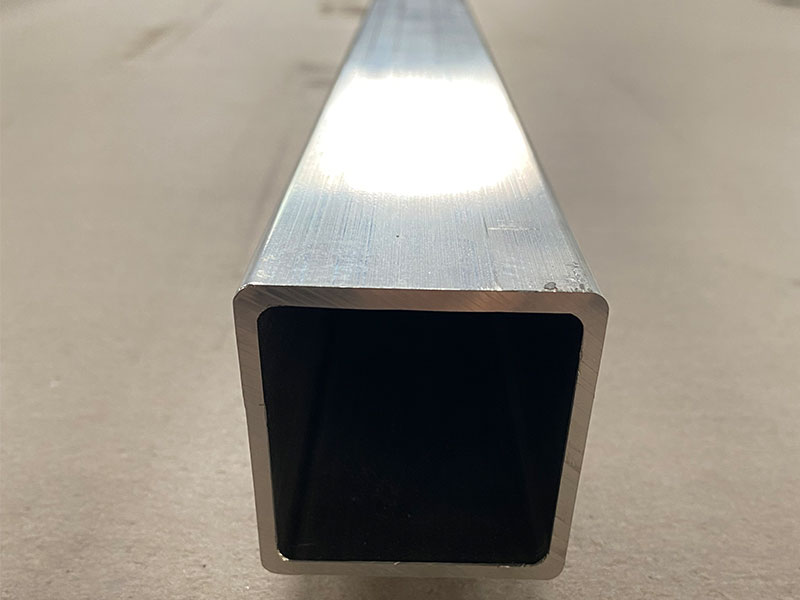

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View DetailsMarine Aluminum Pipe Elbow for Desalination Plant Connections

In modern desalination plants, the choice of piping components is critical to ensuring efficiency, longevity, and resistance to harsh marine environments.

View DetailsAluminum Elbow for Gas and Liquid Transfer on Marine Vessels

Marine vessels operate amidst some of the most challenging environments, where efficiency, durability, and safety of components in fluid transfer systems are paramount.

View DetailsMarine Aluminum Pipe Elbow for Shipbuilding

In the ever-evolving shipbuilding industry, the choice of materials plays a pivotal role in ensuring vessel performance, safety, and longevity.

View DetailsMarine Aluminum Elbow for Pressurized Water Systems on Ships

Explore our high-grade Marine Aluminum Elbow designed specifically for pressurized water systems onboard ships. Engineered for superior corrosion resistance, durability, and compliance with maritime standards, this product ensures reliable fluid dynamics

View Details

Leave a Message