Marine Aluminum Tubes for Marine Equipment Manufacturing

Marine aluminum tubes are specialized aluminum alloy tubes designed specifically for the demanding conditions encountered in marine environments. These tubes are extensively used in manufacturing marine equipment due to their outstanding corrosion resistance, strength-to-weight ratio, and durability against harsh sea conditions.

Features of Marine Aluminum Tubes

Marine aluminum tubes possess unique properties that make them the preferred material in marine engineering. features include:

- Corrosion Resistance: Excellent resistance to seawater corrosion due to protective oxide film and alloy additives.

- Lightweight: Aluminum's low density significantly reduces the weight of marine structures, contributing to fuel efficiency and easier handling.

- High Strength-to-Weight Ratio: Aluminum alloys used for marine tubes provide high mechanical strength while maintaining low weight.

- Formability and Weldability: Easily formed and welded, facilitating custom shapes and assemblies in shipbuilding.

- Thermal Conductivity: Good heat dissipation characteristics for use in heat exchangers and cooling systems in vessels.

- Recyclability: Environmentally friendly, aluminum tubes can be recycled without losing quality, aligning with marine industry sustainability.

Chemical Composition of Typical Marine Aluminum Alloy Tubes

The alloys most commonly used for marine aluminum tubes include 5083 and 6061, both known for excellent marine corrosion resistance and mechanical properties.

| Element | Alloy 5083 (%) | Alloy 6061 (%) |

|---|---|---|

| Aluminum (Al) | Balance (~94.5-97.6) | Balance (~97.9-99.0) |

| Magnesium (Mg) | 4.0 - 4.9 | 0.8 - 1.2 |

| Manganese (Mn) | 0.4 - 1.0 | 0.15 - 0.4 |

| Silicon (Si) | 0.40 max | 0.4 - 0.8 |

| Iron (Fe) | 0.4 max | 0.7 max |

| Chromium (Cr) | 0.05 - 0.25 | 0.04 - 0.35 |

| Copper (Cu) | 0.1 max | 0.15 - 0.4 |

| Zinc (Zn) | 0.25 max | 0.25 max |

| Titanium (Ti) | 0.15 max | 0.15 max |

| Others (Each) | 0.05 max | 0.05 max |

| Others (Total) | 0.15 max | 0.15 max |

Technical Specifications and Mechanical Properties

| Property | Alloy 5083 (Typical) | Alloy 6061-T6 (Typical) |

|---|---|---|

| Density (g/cm³) | 2.66 | 2.70 |

| Tensile Strength (MPa) | 290 - 350 | 290 - 310 |

| Yield Strength (MPa) | 145 - 215 | 240 - 270 |

| Elongation at Break (%) | 12 - 18 | 8 - 12 |

| Hardness (Brinell, HB) | 70 - 95 | 95 - 120 |

| Thermal Conductivity (W/m·K) | 121 | 167 |

| Poisson's Ratio | ~0.33 | ~0.33 |

| Corrosion Resistance | Excellent in seawater | Good, but less than 5083 |

Dimensions and Formats

Marine aluminum tubes are available in various shapes and thicknesses tailored to specific marine applications:

| Dimension | Range |

|---|---|

| Outer Diameter (OD) | 6 mm – 300 mm |

| Wall Thickness | 1 mm – 20 mm |

| Length | Custom cut to required lengths (standard 6 m) |

| Shapes | Round, square, rectangular, oval |

Applications in Marine Equipment Manufacturing

Marine aluminum tubes are applied widely across multiple equipment and structural components where durability, corrosion resistance, and weight savings are crucial.

| Application | Description |

|---|---|

| Shipbuilding | Structural frameworks, pipelines for fuel, oil, water, and air. |

| Railings and Handrails | Corrosion-resistant railings, ladders, and safety barriers. |

| Marine Engines | Heat exchangers, coolers, and exhaust manifolds to improve cooling. |

| Offshore Platforms | Tubular frameworks exposed to harsh corrosive saltwater conditions. |

| Boat Fittings & Fixtures | Light but strong tubes for masts, booms, spars, and hydraulic cylinders. |

| Underwater Piping | Tubes for submersible pumps and underwater transfer systems. |

| Floating Structures | Modular floating docks, pontoons benefiting from lighter load. |

Marine aluminum tubes serve as fundamental components in modern marine equipment manufacturing due to their excellent corrosion resistance, mechanical strength, and lightweight nature. The use of alloys such as 5083 and 6061 ensures that marine vessels and components meet rigorous maritime safety, sustainability, and operational standards.

Choosing marine aluminum tubes guarantees superior marine performance, lower maintenance needs, and improved lifecycle value, making them an unsurpassed material choice for the marine industry.

For detailed quotes, custom sizes, and material certifications, please contact our sales engineering team.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

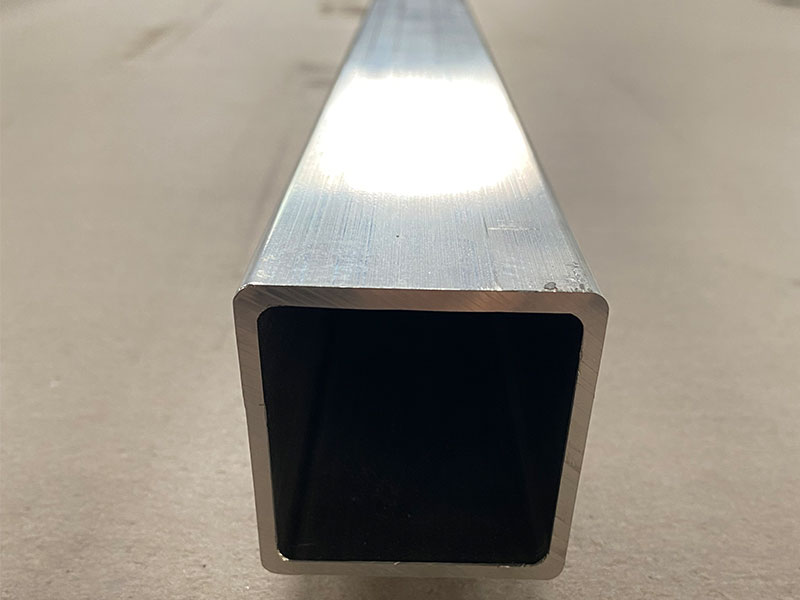

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

High Strength Aluminum Pipe Elbow for Marine Vessels

High Strength Aluminum Pipe Elbows for Marine Vessels are precision-engineered components designed to join and redirect piping systems in demanding shipboard environments.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View DetailsAluminum Elbow for Saltwater Inlet and Outlet Systems

Aluminum elbows play a critical role in saltwater inlet and outlet systems used in marine, industrial, and desalination applications. Manufactured from high-quality aluminum alloys, these fittings are engineered to provide robust, corrosion-resistant.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View DetailsMarine Aluminum Pipe Elbow for Shipbuilding

In the ever-evolving shipbuilding industry, the choice of materials plays a pivotal role in ensuring vessel performance, safety, and longevity.

View DetailsMarine Aluminum Elbow for Fuel System Installations

When it comes to designing and installing fuel systems in marine environments, using the right materials is paramount. Among these materials, Marine Aluminum Elbows is know due to their remarkable properties and advantages.

View Details

Leave a Message