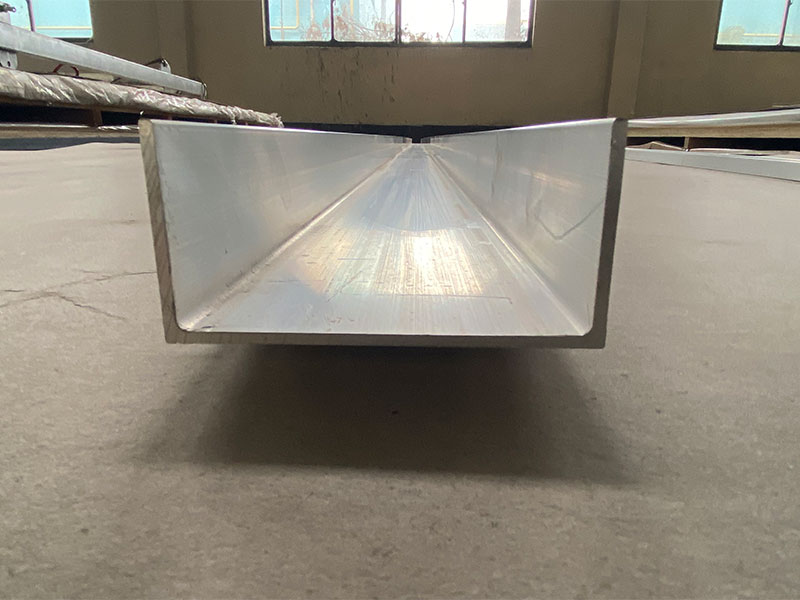

Marine Aluminum Z Shaped Sections for Custom Marine Hull Design

Marine Aluminum Z Shaped Sections are precisely engineered aluminum profiles designed to meet the rigorous demands of marine applications, particularly in custom hull fabrication. These sections serve as vital structural components in the construction of boats, ships, and other marine vessels where strength, corrosion resistance, and lightweight properties are paramount.

Constructed from high-grade marine aluminum alloys, Z shaped sections provide excellent structural support because of their unique geometrical profile. This profile offers enhanced bending resistance and load-bearing capacity, making it ideal for complex hull designs requiring custom structural frameworks.

Features

| Feature | Description |

|---|---|

| Material | Marine-grade aluminum alloy (ammonium precipitated 5xxx or 6xxx series alloys) |

| Shape | Z section profile designed to optimize structural rigidity and ease of welding |

| Corrosion Resistance | Superior resistance due to intrinsic properties of marine alloy + optional anodizing or coatings |

| Weight | Lightweight – reduces overall marine vessel weight, improving fuel efficiency and performance |

| Fabrication | Easily machinable and weldable, with stable dimensional tolerances |

| Customization | Customized dimensions and thickness available to suit unique hull design requirements |

| Environmental Stability | Retains mechanical properties in harsh saltwater and humid environments |

Chemical Composition

Typically, the marine aluminum Z sections use alloys designed for corrosion resistance and mechanical strength suited to marine conditions. The common compositions are based on the 5xxx and 6xxx series alloys.

| Element | 5xxx Series (%) | 6xxx Series (%) |

|---|---|---|

| Aluminum (Al) | 92.5 - 95.0 | 97.5 - 98.6 |

| Magnesium (Mg) | 4.0 - 5.5 | 0.8 - 1.2 |

| Silicon (Si) | 0.4 max | 0.4 - 1.20 |

| Manganese (Mn) | 0.3 - 1.0 | 0.05 - 0.40 |

| Iron (Fe) | 0.4 max | 0.35 max |

| Chromium (Cr) | 0.1 - 0.35 | 0.10 max |

| Copper (Cu) | 0.1 max | 0.15 max |

| Zinc (Zn) | 0.25 max | 0.25 max |

Note: Exact composition will vary depending on alloy grade selected.

Mechanical Properties

| Property | 5xxx Alloy Typical Values | 6xxx Alloy Typical Values |

|---|---|---|

| Tensile Strength (MPa) | 230 - 350 | 240 - 310 |

| Yield Strength (MPa) | 145 - 300 | 155 - 275 |

| Elongation (%) | 8 - 22 | 8 - 18 |

| Density (g/cm³) | ~2.70 | ~2.70 |

| Hardness (HB) | 60 - 110 | 60 - 95 |

Typical temper conditions range from F (as fabricated), H (strain hardened/annealed), to T (heat treated), depending on final applications.

Technical Specifications

| Parameter | Specification / Range |

|---|---|

| Section size (height) | 20 mm – 250 mm |

| Flange width | 10 mm – 150 mm |

| Thickness | 3 mm – 15 mm |

| Length | Customizable, typically up to 6 meters per piece |

| Surface finish | Mill finish / Anodized / Electro-polished |

| Straightness Tolerance | ± 0.5 mm per meter |

| Bend Radius min | 4 x thickness (varies with alloy) |

| Welding compatibility | TIG, MIG, laser welding suitable |

Performance Benefits

- Superior Strength-to-Weight Ratio: Combines lightness for vessel efficiency with structural robustness.

- Increased Longevity: Advanced corrosion resistance reduces degradation and maintenance costs in salty environments.

- Ease of Assembly: Precise section shaping simplifies joining, cutting, and integration within composite hull frameworks.

- Custom Adaptability: Flexibility in dimensioning ensures seamless adaptation to bespoke designs and geometric hull features.

- Fuel Efficiency: Lighter hull structures translate to less fuel consumption and improved operational economy.

Applications in Marine Hull Design

| Application | Description |

|---|---|

| Custom Sport and Fishing Boats | Framework for transoms, decks, and ribs requiring sturdy, lightweight metals |

| Commercial Vessel Hull Linings | Incorporating corrosion-resistant structural framing with high-impact resistance |

| Amphibious Vehicle Structures | Lightweight panels integration for floating and mobility function |

| Yacht Frames and Supports | Aesthetic and functional reinforcement delivering mechanical rigidity |

| Marine Deck Edging & Trim | Resists wear and harsh environmental exposure while maintaining a clean finish |

Related Products

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

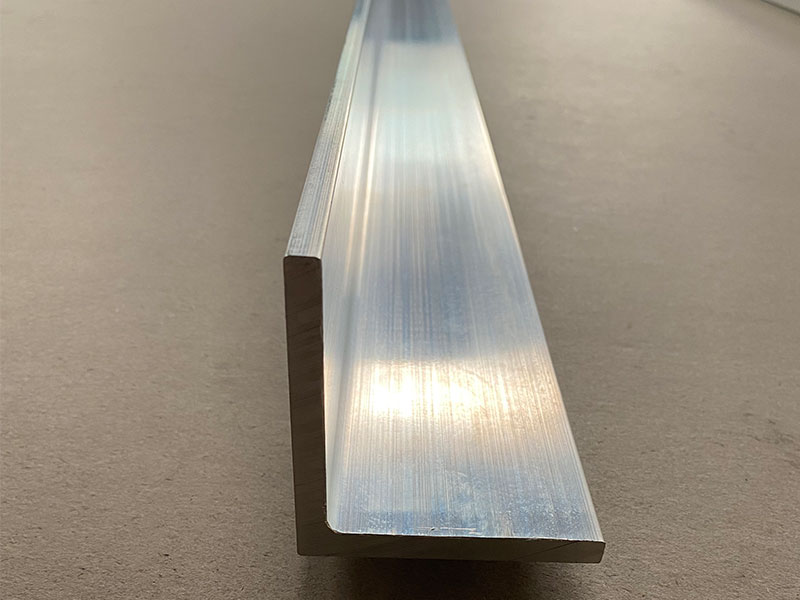

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

6061 Marine aluminum angles

6061 Marine Aluminum Angles are among the most popular and versatile aluminum alloy products used in marine and structural engineering applications. Renowned for their excellent strength, corrosion resistance, and machinability.

View DetailsMarine Aluminum Round Bar for Saltwater Resistant Boat Design

When designing boats destined for saltwater environments, materials selection is paramount for ensuring long-lasting performance and reliable structural integrity.

View Details6082 marine aluminum rod & bar

When it comes to marine applications, selecting the right aluminum material is crucial. Among the various alloys available, 6082 marine aluminum rod and bar is know as the premier choice, perfectly balancing strength, corrosion resistance.

View DetailsMarine Aluminum Flat Bar for Boat Frame Reinforcement and Repair

Superior durability and corrosion resistance of Marine Aluminum Flat Bars, specifically engineered for boat frame reinforcement and repair. Learn about alloy compositions, mechanical properties, tempering conditions, and industry-compliant standards that

View Details5052 Marine Aluminum Z Shaped Sections for Corrosion Resistant Marine Frames

5052 aluminum alloy is widely recognized in the marine industry for its excellent corrosion resistance, formability, and weldability. This lightweight alloy is particularly suitable for marine applications.

View Details5083 Marine Aluminum Z Shaped Sections for Durable Marine Deck Design

5083 marine aluminum Z-shaped sections are characterized by their high-strength properties, exceptional corrosion resistance, and light-weight nature, making them ideal for a range of marine applications, particularly in deck design.

View Details

Leave a Message